Sodium Carboxymethyl Cellulose CMC in Paper Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description:

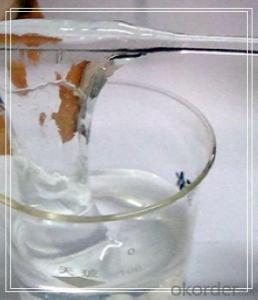

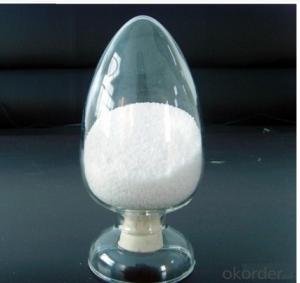

Sodium CarboxymethylCellulose (CMC) is white or yellowish powder that is odorless, tasteless and non-toxic. It has high hygroscopicity and is soluble in water to form a thick liquid. It is a poly anionic electrolyte and not fermented. It has good heat-stability, resistance to salt and film-forming property.

Applications

CMC is used in making pulp so as to improve the retention rate and increase humidity and strength; when used in surface sizing, CMC can improve internal adhesion, decrease printing dust and enhance printing quality as molding reagent. In paper coating, CMC also helps the dispersion and fluidity of paint, improves appearance of paper and smoothness, upgrades optical performance and printing adaptability. Addition: 0.3-1.5%.

.

Properities:

A.CMC is a nonionic water soluble cellulose ether

B.It can be dissolved in water below 60 Deg.C

C.Hardly dissolved in alcohol,chloroform and ether.

D.True specific gravity:1.26-1.31

E.Bulk density:0.25-0.7g/cm3.

F.Charring temperature:225-230 Deg.C.

Specification

Type | Viscosity,cps(25°C) (Brookfield) | PH | Loss on Drying,% | Degree of Substitution | Chloride (cl, %) | purity,% | Usage field |

NX-BW1 | 500-1500(4%) | 6.0-8.5 | ≤8.0 | ≥0.60 | ≤20 | ≥72 |

pulping |

NX-BW2 | 1000-2500(4%) | 6.0-8.5 | ≤8.0 | ≥0.70 | ≤5 | ≥90 |

pulping |

NX-30 | 250-500(4%) | 6.0-8.5 | ≤8.0 | ≥0.80 | ≤2 | ≥98 | Topsizing,coating |

NX-150 | 1000-2000(4%) | 6.0-8.5 | ≤8.0 | ≥0.80 | ≤2 | ≥98 | Top sizing |

NX-300 | 2000-4000(4%) | 6.0-8.5 | ≤8.0 | ≥0.80 | ≤2 | ≥98 | Top sizing |

NX-700 | 400-1000(2%) | 6.0-8.5 | ≤8.0 | ≥0.80 | ≤2 | ≥98 | Top sizing |

NX-5 | 20-50(4%) | 6.0-8.5 | ≤8.0 | ≥0.85 | ≤2 | ≥98 | coating |

NX-10 | 100-250(4%) | 6.0-8.5 | ≤8.0 | ≥0.85 | ≤2 | ≥98 | coating |

NX-BW | ≤20 (2%) | 6.5-9.0 | ≤10.0 | 0.9-1.1 | ≤20 | ≥72 | pulping |

Packaging & Shipping

25kg net Paper bags inner with PE liner.

FAQ

1.When can I get theprice?

We usually quote within 24 hours after getting your inquiry.

If you’re urgent to get the price, please call us or tell us in your email so that we provide price to you priority.

2.What is the terms of payment?

We can aceept the TT ,LC and DP ,you can choose the one which you feel convenient .

Send your message to us

Sodium Carboxymethyl Cellulose CMC in Paper Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords