High Strength SMC Sheet / FRP Sheet Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

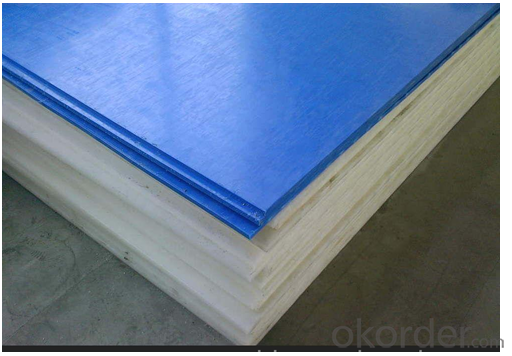

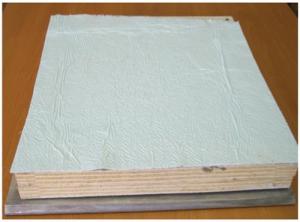

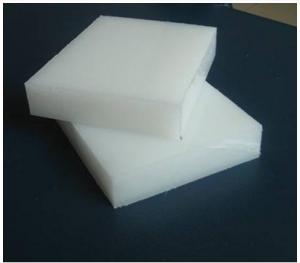

SMC is the short form of sheet mounding compound. This is a raw material for mold pressing. The core is chopped strand and unsaturated polyester resins paste that are covered by LDPE & HDPE sheet. It is 3mm-6mm thick , 600mm-1200mm wide and packing in rolls or boxes. When using , be sure to cut , weigh , uncover film, and join in the heat up mould, after adding high pressure and preserve a time, then you can take off membrane to get the product.

Feature

l Higher mechanical strength

l Excellent leak-proof electrical

l Excellent thermal stability, chemical corrosion resistance

l Low water absorption, good dimensional stability, war page small

l Reliable arc resistance and voltage withstand, high dielectric strength

Specification

Product name | Fiberglass Reinforced Polyester Corrugated Sheet |

Material | High-performance protective film, unsaturated polyester resin, fiberglass |

Layer | 1 layer |

Width | 900mm,930mm,1100mm |

Thickness | 0.8mm,1.0mm,1.2mm,1.5mm,2.0mm,3.0mm |

Length | 5800mm,11800mm or customized according to requirement of customers |

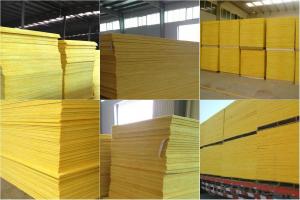

Color: | Clear, Red, Yellow, Green and opal |

Guarantee: | 10 years |

Certification: | ISO9001 SGS ROSH |

Delivery time | 5-7days(general) depend on the style and quantity |

detail features | 1.The light transmission It is between 60-85%. Light through FRP lighting sheet scatters and is mild. It will not form a light band so as to make the indoor brighter. |

Advantage

l Solution of wood steel plastic meter box easy to aging, easy corrosion, poor insulation, poor cold resistance, poor flame retardant, the short life of the shortcomings

l Beautiful appearance, long service life

Application

1. Application in automobile industry

(1) Suspension parts, front and rear bumpers, instrument panels and the like

(2) Car body and body parts, body shell, hard shell roof, floors, car doors, cooling air grille panels, fore plate, spoiler, luggage hatch cover, sun shade, SMC fender, engine bonnet, headlight reflector

(3) The engine cover under parts such as air conditioner shell: wind shield, the intake manifold cover, Fan vanes ring, heater cover, tank parts, brake system components, and the Battery bracket, engine noise barriers and so on

2. Application in electric industry and communication engineering

(1) Electrical housings: electrical switch box, SMC electrical wiring boxes, dashboard cover, etc

(2) Electric elements and electrical parts: SMC insulator, insulated tools, motor cover, etc

3. Application in the explosion-proof electrical equipment shell

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

FACTORY

PACAKGE

- Q: Where are the differences between the products made of stone and resin?

- If the quality of the tree ester products, the release of toxic substances will be more, longer.Of course, the stone now has man-made, with resin produced all kinds of marble and sheet metal.

- Q: What composite material is used for composite manhole covers?

- Composite manhole cover characteristics:The composite manhole cover is reinforced with mesh reinforcement, the key force part is specially strengthened, and the pressure can be quickly dispersed in order to ensure the safety of the vehicle when the inevitable external force impact occurs.No metal, stone plastic well covers and concrete covers, steel skeleton is not enough to cover the total weight of 1/10. Not much of a steal. And because of the high strength of the manhole cover, it is extremely difficult to remove the small steel bar from the well cover. Therefore, thieves do not steal.The inorganic magnesium composite covers high strength, low price, beautiful appearance. The utility model can be painted at will, convenient for installation, maintenance and identification, and completely solves the problem of anti-theft because of no recycling value. Our country will gradually change the composite manhole cover in the next three to five years, and the market potential is enormousInorganic composite manhole cover. Honi is made of a new type of high strength inorganic composite material and glass fiber. Belongs to mid-range manhole cover products.

- Q: What is the difference between plastic die casting and compression molding? Please be specific

- In recent years, press molding has been applied to thermosetting blends such as urea formaldehyde plastics, phenolic resins, epoxy resins, melamine resins, and rubber. Although some materials are available for injection molding, compression molding is still very common. Die casting material is more flexible than plastic material. Many thermosetting materials with high impact (1.0ft lb) and good notched impact strength retention, only in the limit under pressure will flow.

- Q: Is the quality of the resin wall the same?

- From the material, divided into SMC sheet processing background wall and BMC group processing background wall, in which the SMC background wall high strength, board size can do relatively big, and BMC background wall can only do small size board.

- Q: Which is good for SMC composites and honeycomb composites?

- 3D printing can now print cellular structures directly.

- Q: What are the raw materials for composite manhole covers?

- The composite manhole cover adopts high temperature and high pressure molding technology with high degree of polymerization, large density, good impact resistance and tensile strength, and has the advantages of wear resistance, corrosion resistance, no rust, no pollution, no maintenance, etc.. General composite manhole covers are also BMC composite cover and SMC composite manhole cover. SMC polymer composite manhole cover, Beijing Pan Asia Telecom's reliable, but also applied for the color of the patent

- Q: Who knows what is the process flow of FRP splicing water tank?

- Description of production process of glass fiber reinforced plastic water tank:Raw material purchasing: resin paste, glass fiber, laminating, coiling, thickening, cutting, weighing, molding, dressing, drilling, assembling.The prepared raw material is prepared according to a prescribed proportion, and then the paste is stirred into a resin paste; the resin paste and the glass fiber yarn are impregnated with SMC sheets to form a SMC sheet;

- Q: Where can I supply the SMC sheet machine set?

- If it is here in Shandong, Yantai, I know that Yantai Laizhou Feng based Machinery Co., Ltd., the production of SMC sheet machine set is good. Before, with the company Yang boss had traded

- Q: What is the use of resin fiber powder extracted from the circuit board without breaking the law?

- (1) high tensile strength and small elongation (3%).(2) high elasticity and good rigidity.(3) the elongation within the elastic limit is large and the tensile strength is high, so the impact energy is large.(4) for inorganic fiber, with non flammable, chemical resistance.(5) water absorption is small.(6) the scale stability and heat resistance are excellent.(7) good processability, can be used as stock, bundle, felt, weaving and other forms of products.(8) transparent and permeable to light(9) the development of surface treatment agents with good resin properties.(10) the price is cheap.

- Q: Composite manhole cover or cast iron well cover?

- The raw material of the composite manhole cover is made of resin, which is cheaper than the increasingly scarce steel material, so the color composite manhole cover is cheaper than the cast iron manhole cover.

Send your message to us

High Strength SMC Sheet / FRP Sheet Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches