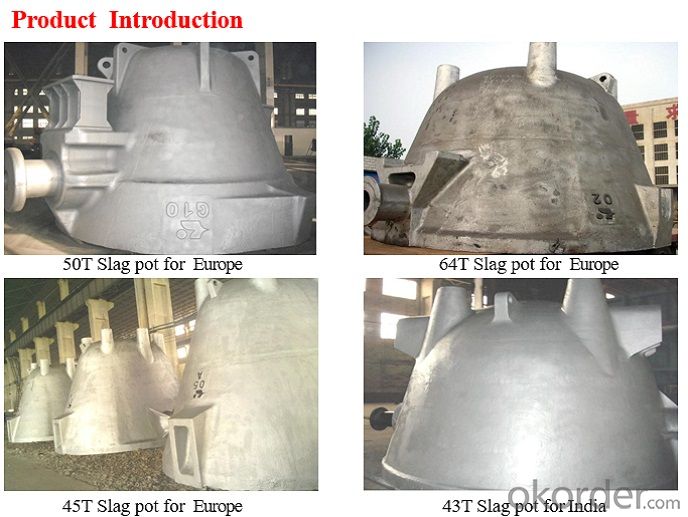

Slag Pot with Good Quality Hot Sale for Steel Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Slag Pot

The slag pot is a metal ladle for collecting molten slag flowing from the taphole of a steel-smelting furnace during smelting. It is positioned under the furnace on a car that moves along a special trestle.

Company Profile

CNBM International Corporation (CNBM International) is one of the primary subsidiaries of CNBM Group, and has established strategic partnerships with hundreds of domestic manufacturers and sounded business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches more than 5 countries with a view of achieving localization, which also represents an essential progress in our globalization target.

We specialize in Metallurgical product, such as Slag pot, Valve, pump, BOF Lance Tip, Slag pot transfer car, Mill rolls, Bearing etc. We supplied our Slog pot to Korea, Europe, Japan , America, Mexico, India, Vietnam, Australia etc.

Our products comply with relevant European and International standards and are all manufactured under the quality management system ISO 9001. Very proud to say that each one of our products possesses high quality and competitive price, let alone having been exported worldwide and built up great reputation in quality and service among global customers.

Lab&Test Equipment

Inspection requirements and standards

Nondestructive Testing (NDT) requirements

1) The magnetic particle inspection (MT) and ultrasonic inspection (UT) of trunnion are conducted according to the general technical conditions of heavy machinery JB / T 5000.15-2007, and the forged steel parts are not damaged. The test was carried out at level II.

2) Magnetic particle inspection (MT) and ultrasonic inspection (UT) of slag tank body shall be in accordance with GB / t9444-88 grade III and GB / t7233-87 grade III respectively. Magnetic particle inspection area

Domain: trunnion area of slag tank, all r-corners outside and inside of slag tank.

3) Ultrasonic flaw detection area: inner bottom diameter of slag tank is 1m: wall thickness of 9 places randomly measured by ultrasonic testing. (the Seller shall provide corresponding rulerInch report and NDT report)

4) Ensure that the slag tank is cast and formed at one time without cold separation; after finishing, no welding point is allowed.

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- You oily sludge!Is not the general market on the soil?If it isPlease use two groups of chemicals to reinforce the soilOr suggest your company?Do the putty or paint film after doingThat's better

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- Good welding of low carbon steel (alloy), probably because the weld workpiece rigidity, fast cooling, the weld internal crystallization of brittle microstructure (martensite), so after welding or welding process welding using self heat, reasonable arrangement of weld, welding seam and heat affected zone heat treatment. The welding heat treatment is often used to preheat before welding, after welding withasbestos cloth covering slow cooling annealing, reach the purpose, its main function is to reduce the internal stress, improve the weld microstructure of martensite formation, reduce brittle tendency, preventing welding cracks.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angleEspecially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- 3, weight: if reinforcement in products, casting weight is generally greater than the welding parts (the internal organizational structure and mode of production determines the mechanical properties of materials, so it determines the weight of the product), considering the cost of transportation, certain priority structure.

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- Yes, casting drawings are casting drawings with machining allowances, slopes, and gating systems

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- Not processed, do not understand your problem... There's something wrong with the drilling machine. Please call me

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- If is casting, internal shell mold may be not completely dry, strength is not enough, resulting in shell mold collapse into molten steel.It is also possible that the refractory is not refractory enough.

- Q: How can the casting be free of trachoma?

- 2, pouring temperature should be enough, otherwise the sand can not float up;

Send your message to us

Slag Pot with Good Quality Hot Sale for Steel Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches