Sk36 High Alumina Fireclay Brick for Smelting Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Physical Properties And Chemical Composition For High Alumina Refractory Brick :

| Items | Index | ||||

| SK-38 | SK-37 | SK-36 | SK-35 | SK-34 | |

| Al2O3 %,≥ | 75 | 65 | 55 | 48 | 42 |

| Cold Crushing Strength, MPa ≥ | 54 | 49 | 44 | 40 | 20 |

| Apparent Porosity, % ≤ | 23 | 23 | 22 | 22 | 26 |

| Refractoriness Under Load, °C ≥ | 1520 | 1500 | 1470 | 1420 | 1300 |

| Linear Change on Reheating, [1500°C×2h]% | +0.1-0.4 | +0.1-0.4 | +0.1-0.4 | [1500°C×2h] +0.1-0.4 | 0-0.5 |

| Refractoriness, °C ≥ | 1790 | 1790 | 1770 | 1750

| 1730

|

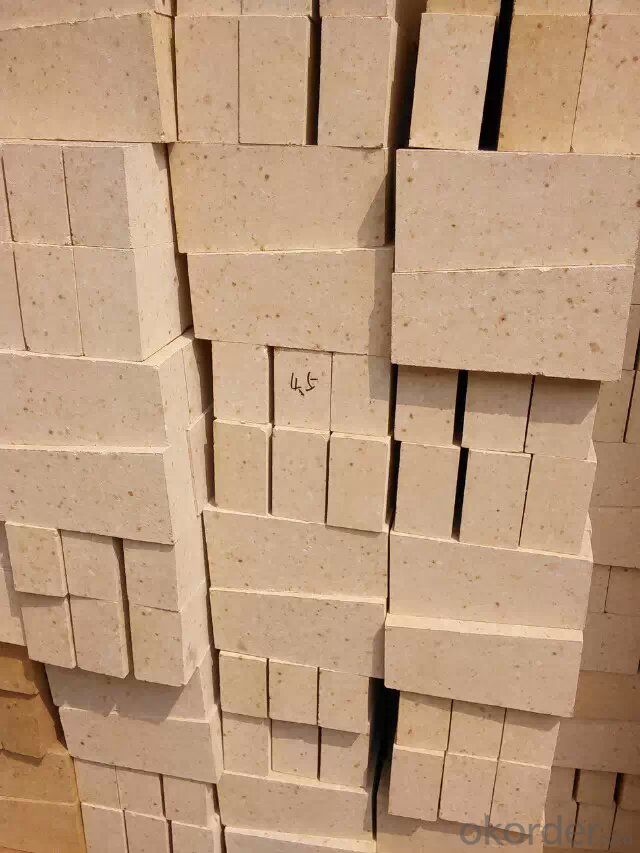

Product Photoes For Different Type:

Packaging & Shipping:

The bricks are packed on wooden pallet with papers in each layer and PP film wrapped outside of the whole pallet.

Company Information:

our company located in the hinterland of Central Plains, at the foot of Songshan Mountain, and adjacent to Zhengshao Highway, Longhai and Jingguang railways. The convenient transportation, abundant resources and high quality minerals provide favorable conditions for the production of refractory materials.

Established in the early nineties of twenty century, with continuous innovation and development, now it is a comprehensive enterprise in refractory material sindutry, covering metallurgy, building materials, electric power, chemical industry etc.

Our main products: refractory material for industrial furnaces, such as high-alumina brick, clay brick, silicon brick, high-strength diatomite brick, light weight insulation brick, low iron mullite brick, etc;anti-stripping alumina brick,alkali proof brick,phosphate brick for cement industry; For the industrial furnace and power boiler, we can provide various series of abrasive bricks,corundum brick, mullite brick, wear resistant castable, corundum castable , high strength low cement castable, impervious material,plastick refractory, etc. Our products are popular in the whole country and have been exported to India, Iran.etc.

Rong Sheng company adhering to the " integrity,innovation, hard work" and business philosophy,the " people-oriented" as the cornerstone of enterprise development, to " the pursuit of excellence" as the core values of the enterprise, will create " Rongsheng Brand" as a corporate strategic objectives.and product types rich scientific management processes, improve customer information management system, timely, efficient, to provide satisfactory service to our users.

FAQ:

1. Are you a manufacture or trading company ?

Factory+ trade(mainly factories, at the same time, we operates other related products)

2. Can we visit your factory ?

Sure,welcome at any time, seeing is believing.

3. Is your company accept customization ?

We have own factory and excellent technical team, and we accept OEM service

4. What’s the MOQ of trial order ?

No limit, we can offer the best suggestions and solutions according to your condition.

5. Will your company supply samples ?

Yes, we do. The shipping charges should be undertaken by customer.

- Q: Glass curtain wall and floor between the gap how to deal with, seeking expert solution?

- 5mm galvanized iron clad bag> 100mm thick rock wool close to the curtain wall glass, reserved 2-3mm gap, weathering rubber seal, so as to avoid thermal expansion and contraction of glass broken, the treatment of the upper available Wooden feet to do the skirting, the outside can be painted stone or aluminum plate to do decoration. The purpose of the curtain wall is to prevent the fire from going up after the disaster and then the noise. Outside the side if the curtain wall glass transparent, then in the galvanized steel outside the surface brush decorative fluorocarbon paint.

- Q: Pipeline insulation materials, which are generally several types of fire protection

- According to the relevant standards of GB8624-9, the burning performance grade of building materials is divided into the following four grades: Class A: incombustible building materials: almost no combustion. B1 level: flame retardant building materials: a good flame retardant effect, in the air case of fire or high temperature is not easy to fire, not easy to spread, and in the open fire will immediately stop burning. B2 grade: flammable building materials: a certain role in the fire, in the air in case of fire or high temperature will immediately fire burning, easy to lead to fire spread, such as wood structure housing. B3 level: flammable Building materials: no fire retardant effect method often weary end of the whole take the whole household, easy to burn, fire a great danger. Pipeline temperature material varieties can be divided into inorganic insulation materials, organic insulation materials and composite insulation materials three types: 1. inorganic insulation materials are common: rock wool board, glass beads insulation mortar, foam cement board, glass wool Plate and so on (inorganic insulation material fire rating is usually A level). 2. Organic insulation materials are common: molded polystyrene board, phenolic resin board, polyurethane board (organic insulation material fire rating is usually B1 level). 3. Composite insulation materials are common: composite silicate insulation (A) and so on.

- Q: Height greater than 60m residential building construction, when the use of B1-class insulation material, every few layers to set the level of fire isolation belt?

- Now the external wall insulation materials are required to reach A level, see "Gong [2017] 65"

- Q: Production of fire paint business should have what qualifications

- (License, organization code, tax registration certificate, system certificate, etc.) and type approval certificate, such as the new plant had to use the environmental assessment and other information (such as the use of environmental protection,

- Q: Extruded board fire B1, B2 grade material how to distinguish

- Extrusion board fire B1, B2 grade material distinction: B2 level for the slow combustion level, that is, after the fire will not become larger, and the drop will not ignite the filter paper; B1 level from the asphyxia, that is, leave the fire After the automatic extinguished, or 10 seconds off. Extruded board is extruded polystyrene insulation board, it is polystyrene resin as raw materials with other raw materials and additives, through a special process of heating at the same time into the catalyst, and then continuous extrusion (XPS), XPS has a perfect closed-cell honeycomb structure, this structure allows the XPS board has a very low water absorption. It is known as the thermal insulation with extruded polystyrene foam (XPS) (Almost no water absorption), moisture-proof, airtight, light, corrosion resistance, low thermal conductivity, high pressure resistance, anti-aging (normal use almost no aging decomposition), long life, low thermal conductivity Energy saving and environmental protection insulation materials. Due to the continuous extrusion caused by the tight closed-cell structure. Its density, water absorption, thermal conductivity and steam permeability are lower than other types of sheet metal, is the market recognized the best insulation materials. Extruded board of fire grade classification is more detailed, there are B3, B2, B1 three levels (A level on the current science and technology can not be achieved), which B3 level for the ordinary board, that is, the fire, and the fire is growing ; B2 level for the slow combustion level, that is, after the point of fire will not become larger, and the drop will not ignite the filter paper; B1 level from the asphyxiation level, that is, after leaving the fire automatically extinguished, or 10 seconds off.

- Q: Indoor to do with the gypsum board or good or good use of fire board board, fire board is made of what material ah how environmental

- Gypsum board can, low cost Of course the best for wood. Fire board is a particle board or density board paste the skin, which contains plastic, formaldehyde content of course, it is difficult to distinguish the quality of good or bad.

- Q: Fire doors with fire insulation materials which?

- Fire doors with fire insulation materials fire doors made of steel materials, door frames, door frames and door panels, doors if filled material, then fill the human body non-toxic harmless fire insulation materials, and with fire hardware accessories With a certain fire resistance of the door. Fire doors general technical conditions of the standard This standard specifies the wood fire door product classification, size specifications, technical requirements, test methods, inspection rules, logo packaging, transportation and storage. This standard applies to the use of wood or wood products for the door frame, door frame, door panel fire door. Emergency and statistical functions, the system can automatically display on the computer specified cardholder's physical location, easy to contact in time. Fire and other emergencies, the electronic fire door will automatically open, easy to escape, the entrance can also be automatically opened; when the illegal out of time, will automatically alarm.

- Q: What is a level of fire. Secondary fire, three fire (steel)

- Is to see you fire for hours. General secondary fire is 1.5 hours it

- Q: Wood-plastic material fire?

- Fire rating is classified. Can not simply say that wood-plastic material fire or not. According to the composition of wood-plastic materials, which is mainly plastic and wood powder, in order to increase the fire resistance of wood-plastic, plus a certain amount of flame retardants, but the type and number of flame retardants and a direct impact on the fire for the box The performance of the valley. At present, many wood-plastic materials, the highest level of fire should be in the B1 level, the need for a stronger fire rating, then the need for special formula, many companies can not do a class A fire rating. Detailed advice ::...

- Q: Polystyrene board is A-class or B-class fire insulation materials

- Should be C level, if the composite inorganic sheet should be B-class material...

Send your message to us

Sk36 High Alumina Fireclay Brick for Smelting Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches