Raw Materials for Refractory:Sintered Spinel Al2O3 58-62 MgO 28-32

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Shandong, China

· Shape:particle or powder

· Material:Alumina

· Al2O3 Content (%): 58-62%

· Mgo Content (%): 28-32%

· Fe2O3:1.8%max

· SiO2Content (%): 2.7max

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy or Refractory

· Product name:Sintered spinel

· Color:White or grey yellow

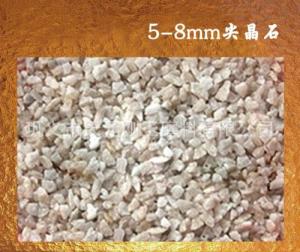

· Size:100MESH/200MESH/0-1MM/1-3MM/3-5MM/0-40MM or as customer's request

· Certificate:ISO9001

· Usage:Refractory

· Type:Refractory raw materials

· shape:particle or powder or clinker

· Packaging Details:Bags/In bulk/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

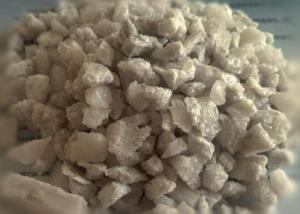

Q: Do you have pictures?

A: Yes, please check the pictures:

- Q: What is the best refractory company?

- Recently, many of the activities of palladium ah, find a few big beauty shoot videos, but also to send jewelry, and draw, seems to be the need to vigorously develop the market China.

- Q: how to divided the external wall thermal insulation materials fire rating

- Level A: Incombustible building material: It is a kind of material that almost does not occur burning. Level B1: Nonflammable building material: Non-flame material has good flame resistance. It is difficult to fire under the condition of open fire in the air or high temperature, and it is not easy to quickly spread, and when the combustion?source is removed, the combustion will stop immediately. Level B2: Combustible?building?materials: Flame material has a good flame resistance. In case of fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as wooden column, timber roof truss, timber beam and wooden stairs. Level B3: Combustible?building?materials: It has no any flame resisting effects, and is easy to burn, so the fire risk is high.

- Q: The development prospect of fire-resistant material

- Concrete has a broad employment direction while refractory material is not in popular demand. But if you do well, you are one of ethe experts.

- Q: What is the most reasonable drying heating curve of magnesia refractories? Products of less than 0.5T

- o

- Q: What's the material of electrical fire prevention board?

- Industrial electrical fire prevention board is mainly aimed at fire protection and thermal insulation. Iron plate is electrically conductive with good thermal conductivity, which will cause the result that the equipment is not insulated and suffers larger superheating surface! ! ! !

- Q: What do refractory materials include?

- What refractories are included? Refractories include AZS brick, corundum brick, direct-bonded?magnesia-chrome, carborundum brick, silicon nitride bonded silicon carbide brick, non-oxide refractory materials such as nitride, silicides, sulfides, borides and carbides, oxidation calcium, chromium oxide, aluminum oxide, magnesium oxide and beryllium oxide.

- Q: What's the type of fire proofing thermal insulation materials?

- Aluminum silicate: AlSiO3 With flint clay clinker as raw material, aluminum silicate is made by resistance or electric-arc furnace fusion and then spraying processing. Aluminum silicate fiber, also known as ceramic fiber, is a new lightweight refractory material featured by light weight, high temperature resistance, good thermal stability, low heat conduction rate, small heat capacity, good mechanical vibration resistance, small thermal expansion and good thermal insulation. It can be processed into aluminum silicate fiber board, aluminium silicate fiber felt, aluminium silicate fiber rope, aluminium silicate fiber blanket, etc. Featured by high temperature resistance, low heat conductivity coefficient, light weight, long life, good tensile strength and elasticity and no toxin, this new sealing material is an alternative of asbestos and widely used for thermal insulation of thermal energy equipment in metallurgy, electric power, machinery, chemical industry, etc.

- Q: What are the fireproofing materials of the external wall included?

- According to the external wall thermal insulation materials, the external insulation materials is in general divided into Class A and Class B. The A class is non-combustible material. The B class is combustible materials. The fire disasters of the CCTV building and Shenyang hotel are both caused by the B level materials. Generally, the A level material will be used, and some prices are even cheaper than the B-grade material. A level is roughly divided into thermal?mortar, phenolic foam Board, rock wool board, foam cement board, and so on. I hope my answer will help you!

- Q: What is neutral refractory? Can refractory suppliers tell the main components of it?

- The material using Al2O3, clay, bauxite and corundum as the main components is neutral material; the material using MgO and CaO as the main components is basic material; the material using SiO2 as th emain component is acidic material.

Send your message to us

Raw Materials for Refractory:Sintered Spinel Al2O3 58-62 MgO 28-32

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords