Sintered Mullite/Calcined Mullite made in China for Refractory Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief introduction of calcined mullite :

calcined mullite can be divided into shaped refractory products(Such as: Refractory brick ,Fire clay brick,High alumina brick, Heat insulation brick,Ceramic fiber products ect) and unshaped refractory materials(Such as:Refractory castable, Plastic refractory, High temperature refractory mortar ect), Widely used in metallurgy, petroleum, chemical industry, Cement, Glass, Casting,carbon,building materials, machinery processing, military, etc.

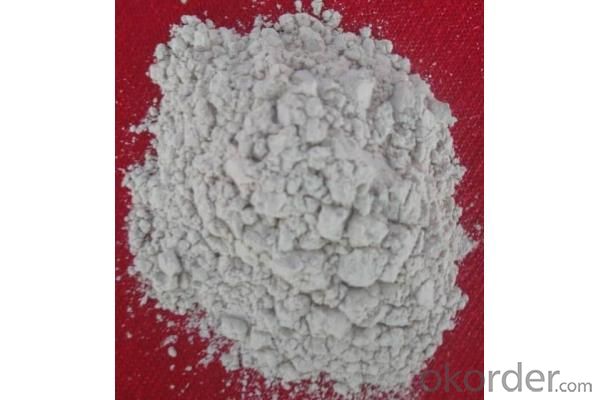

Refractory raw material of calcined mullite : The chamotte, Calcined flint clay, Calcined kaolin, Sintered mullite,Bauxite,flint clay, aggregate, fused mullite

process of calcined mullite :

Made from the natural high quality bauxite, our product is through multi-level homogenozaotpm and then calcined at about 1750 degree. it possesses many good characteristics such as high bulk density, stable quality, good thermal shock resistance, small index of high temperature creep and good resistance to cheamical corrosion, it is an ideal raw aterial for the following refractory products like a variety of shaped and unshaped refractories, advance ceramic asanitary ware body, precision casting models and so on.

Application of calcined mullite : metallurgy, petroleum, chemical industry, building materials, machinery processing, military, etc of thermal technology equipment.

Mullite, coke store and aggregate chemical analysis of calcined mullite :

Name | Mullite sand, coke store aggregate

| Mullite powder, calcined powder | |||

Super class | First class | Super class | First class | ||

AL | 45-48 | 43-45 | 45-48 | 43-45 | |

SI | 51-53 | 51-53 | 51-53 | 51-53 | |

Refractoriess | 2.60 | 2.50 | 5.60 | 2.50 | |

Dustiness | 0.10 | 0.10 | |||

Pictures:

Our air protection vertical kilns( the biggest in china)

our factory and refractory material

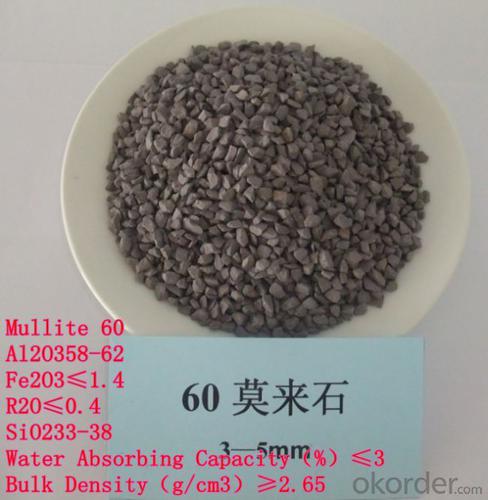

mullite sand

- Q: what's the seal of fireproofing material?

- Folded organic putty takes organic material as bond,it has certain flexibility or plasticity while using, and it's products are thick liquid or cement shaped object. Folded WXY-II is powered?solid that takes inorganic materials as main components, it has certain workability while used with admixture. Folded fire retardant bag is the packaged object made by fireproofing material, and it's suitable for fireproofing seal of larger openings or fire separation of cable?bridge(fire retardant bag also refers to fireproof bag) Folded fire retardant module is the solid made by fireproofing material with certain shape and size, and it is easy for cutting and drilling, suitable for fireproofing seal of opening and cable?bridge. Folded seal board is made by fireproofing material, it's easy for cutting and drilling, suitable for fireproofing seal of large opening. Folded foam seal is a kind of fireproofing material that can automatically expand and foam and sealed by opening after injecting the foam into opening. Folded sealing strip is a product or flexibility coiled material mede by fireproofing material with certain geometry shape. Folded sealing gum is a kind of liquid fireproofing material that has a function of fireproofing and sealing. Folded fire retardant bag is soft and windable tape-shaped product made by fireproofing material, it is winded on the external surface of plastic pipe and fixed with steel belt or other proper methods, it's the expansion, squeezing and softening pipe after contacting with fire, opening left by burning or soften of seal plastic pipe. Folded fire retardant ring is the product made by fireproofing material and metal shell, it's covered on the external surface of the plastic pipe, expanding and sealing after contacing with open fire, the opening left by burning and soften of plastic pipe when it passes through the opening of wall and floor.

- Q: What are the fire endurance requirements of class A fire resistant door ?

- Fire endurance of class A fire resistant door is 1.5h. According to the latest fire door requirements, in FMA FMB FMC three forms, A, B and C represent categories, such as FMA on behalf of Class A fire doors (ie thermal insulation fireproof door). Fire endurances of class A,B and C fire doors are 0.5 1.0 1.5 2.0 3.0. Therefore, the fire resistance of fire door needs to be designed and the design paper will make it clear in general.

- Q: Are fire materials poisonous after burning?

- High temperature oxide materials in refractory special applications, such as aluminum oxide, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, refractory compounds, such as carbides, nitrides, borides, silicides and sulfides; high temperature composite materials, including metal ceramics, high temperature inorganic coatings and fiber reinforced ceramics.

- Q: How about the prospect of refractory material?

- Area depends the market. Resource-based industry

- Q: Where is the distributing center of refractory materials in China?

- The infrastructure is perfect, service and refractory chemical industry professional market ancillary services, information, transportation, food, housing, and other one-stop perfection. The business service center, Yongan business city, Fukang company, Xu Bai Anlong logistics center and the market has been basically formed, the market in more than 200 dressing rooms at the end of September put into use, logistics center, warehouse industry nearly twenty thousand square meters can use for customers. The Fasthotel, the dormitory and the information center will be ready for delivery, and large transport teams will be built to provide accommodation, freight and other convenient services for the owners.

- Q: What's the heat conductivity coefficient of fire-resistant material?

- 5~5 (Unit: W·m-1·K-1). The symbols are λ or K. Thermal conductivity and material properties Thermal insulation material generally is 0, and is related to organizational structure and working temperature. Thermal conductivity of the material refers to the heat transferred from from one plane to another plane in 1 seconds. Generally the thermal conductivity of fire-resistant material is 1. The larger the value is, the stronger the thermal conduction performance is. If the temperature of two planses differes for 1K, then the thermal conductivity is 03~1. The plane cover 1square meter.

- Q: What things and cement mixed can act as refractory?

- Cement acts as cementing material. Itself works by refractory aggregate and stir the refractory material for its gelling refractory aggregate both should be fire-resistant.

- Q: I would like to know if there is any requirement for refractories in the crucible type high-frequency smelting furnace Worry! I hope you can help me! This time!

- Stable chemical properties. The crucible material should not be hydrolyzed at low temperature. It is difficult to be decomposed and reduced at high temperature and is not susceptible to corrosion by molten slag and molten metal;

- Q: What are the types of refractory sealant?

- Hello: I'm glad to help answer your questions! Measure fireproof material is high polymer plastic seal material which is used for seal. It has a dual performance of both sealing and fireproofing. It can be applied for fire protection construction of metal pipes, thermal insulated pipes and construction juncture. Fire-resisting sealant has an expansion rate of greater than 20% and it is resistant to nuclear radiation, LOCA, detergents, and it has radioactive decontamination performance. It has a durability of more than 40 years; It is free of halogen, sulfur and other toxic matters, watertight, anti-smoke, corrosion free, safe and environmental-friendly. It gives off no toxic smoke and is efficient in inflamming retardancy which is easy to construct. I hope my answer will be helpful to you.

- Q: what is the material of fixed first rate fire resistant window?

- Window frames and fireproofing glass, fire sealing strip, fireproofing glass mound layer, which is infexible fan, and the flexible fans have to plus folding and closing window cleaner. (3) window frames must be integral with the building, using wood or iron to connect the wall. After the installation of the steel frame, the cement mortar must be watered between the window frame and the wall, and it should conserve more than 24 hours before normal use.

Send your message to us

Sintered Mullite/Calcined Mullite made in China for Refractory Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords