Simple Single Side Bracket for Ten Level House Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

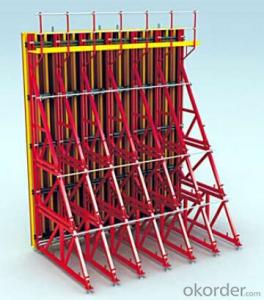

1. Structure of Simple Single Side Bracket

Compared with single-side bracket, it is small in sizes and easy to assemble & dismantlement. So the transportation and piling up is convenient. The maximal pouring height is 3.0m.

2. Main Features of Simple Single Side Bracket

Economical and safe anchoring

Stable and cost-effective for high loads

Simple and flexible planning

3. Simple Single Side Bracket images

4. Simple Single Side Bracket Specifications

The M30/D20 climbing cones have been designed especially for single-sided concreting using .SCB180 in dam construction, and to allow the transfer of high tensile and shear forces into the still .fresh, unreinforced concrete. Without wall-through tie-rods, finished concrete is perfect.

5. FAQ of Simple Single Side Bracket

1) What can we do for you?

.We can ensure the quality of Simple Single Side Bracket and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

- Q: Can steel props be used in shopping mall construction?

- Yes, steel props can be used in shopping mall construction. Steel props, also known as adjustable steel props or steel shoring props, are commonly used in the construction industry to provide temporary support to structures. They are typically used during the construction of multi-story buildings, including shopping malls, where additional support is required for heavy loads and during various stages of construction. Steel props are adjustable in height, making them versatile and suitable for different construction needs. They are designed to provide stability and safety to the structure and can be easily installed, maintained, and removed as needed. Overall, steel props are a reliable and commonly used solution in shopping mall construction.

- Q: Can steel props be used for supporting temporary fencing or barriers?

- Yes, steel props can be used for supporting temporary fencing or barriers. Steel props are sturdy and durable, making them ideal for providing support to temporary structures. They can easily bear the weight of temporary fences or barriers and ensure stability and security. Additionally, steel props can be adjusted to different heights, allowing for flexibility in setting up temporary fencing or barriers in various locations and terrains. Overall, steel props are a reliable choice for supporting temporary fencing or barriers.

- Q: Can steel props be used in temporary support of overhead cranes?

- Yes, steel props can be used in the temporary support of overhead cranes. Steel props are commonly used in construction and industrial applications to provide temporary support for heavy loads, including overhead cranes. Their strength and stability make them suitable for safely supporting the weight of cranes and ensuring a secure working environment.

- Q: Can steel props be used for temporary shoring?

- Yes, steel props can be used for temporary shoring. Steel props are adjustable supports that provide temporary support to structures during construction or renovation work. They are commonly used in the construction industry to support walls, beams, and floors, as well as to stabilize structures during excavation or demolition. Steel props are preferred for temporary shoring because they are strong, durable, and can be easily adjusted to different heights. They can also be used in a variety of conditions, including uneven ground or confined spaces. Additionally, steel props are designed to distribute the load evenly, ensuring the stability and safety of the temporary structure. Therefore, steel props are a reliable and effective solution for temporary shoring needs.

- Q: Can steel props be used for temporary support in residential buildings?

- Yes, steel props can be used for temporary support in residential buildings. Steel props are commonly used in construction to provide temporary support during building works, renovations, or repairs. They are adjustable and can bear heavy loads, making them suitable for providing temporary support in residential buildings where additional support is needed.

- Q: Do steel props require any additional accessories for installation?

- Yes, steel props typically require additional accessories for installation. These accessories may include base plates, swivel foot plates, adjustable heads, and pins. Base plates are used to provide stability and distribute the load evenly on the ground. Swivel foot plates are used to adapt to uneven surfaces and prevent slipping. Adjustable heads allow for fine-tuning the height and supporting different types of structures. Pins are used to secure the props in place and prevent them from collapsing. These accessories are essential for ensuring the safe and proper installation of steel props.

- Q: What are the potential environmental impacts of using steel props?

- The potential environmental impacts of using steel props include the extraction of raw materials (iron ore and coal), which can lead to habitat destruction and air and water pollution. The manufacturing process of steel props also consumes large amounts of energy and emits greenhouse gases. Additionally, the disposal of steel props at the end of their lifespan can contribute to landfill waste. However, steel props can be recycled, which can mitigate some of these impacts.

- Q: Can steel props be used for temporary support in stadium roof construction?

- Yes, steel props can be used for temporary support in stadium roof construction. Steel props are commonly used in construction projects to provide temporary support to structures such as walls, beams, or roofs. They are adjustable and can be easily installed and removed as needed. Steel props are strong, durable, and can withstand the weight and pressure of the roof during construction. They provide stability and support, ensuring the safety of the workers and the integrity of the structure.

- Q: How do you store steel props when not in use?

- When steel props are not in use, it is important to store them properly to ensure their longevity and maintain their functionality. Here are some steps to store steel props effectively: 1. Clean and inspect: Before storing the steel props, make sure to clean them thoroughly to remove any dirt, debris, or rust. Inspect the props for any damages or signs of wear and tear. 2. Disassemble if possible: If the steel props can be disassembled, it is recommended to do so before storage. This will help save space and prevent any possible damage during storage. 3. Keep them dry: Steel props should be stored in a dry environment to prevent corrosion. Moisture can cause rusting, which can weaken the props over time. 4. Organize and stack properly: When storing steel props, it is important to organize and stack them properly to optimize space and minimize the risk of accidents. Place the props in a secure and stable position, ensuring they are not leaning against anything that might cause them to fall. 5. Use protective coverings: If possible, consider using protective coverings such as plastic or fabric to shield the props from dust and moisture. This will help to further prevent rust and keep the props in good condition. 6. Store in a suitable location: Find a storage area that is cool, dry, and well-ventilated. Avoid areas prone to high humidity or extreme temperature fluctuations, as these conditions can accelerate rusting or other damages. 7. Label and document: To make it easier to locate and identify the props later, consider labeling and documenting them. This can be done by attaching tags or labels with relevant information such as sizes, quantities, or any specific details about the props. By following these storage guidelines, you can ensure that your steel props remain in optimal condition for future use, saving you money and time in the long run.

- Q: Can steel props be used for supporting temporary sports field structures?

- Yes, steel props can be used for supporting temporary sports field structures. Steel props, also known as adjustable steel props or steel acrow props, are commonly used in construction and temporary structures to provide support and stability. They are designed to withstand heavy loads and are adjustable in height, making them suitable for a variety of applications. When it comes to supporting temporary sports field structures, such as bleachers, temporary grandstands, or stages, steel props can be an ideal choice. They offer a high load-bearing capacity, ensuring the safety and stability of the structure even when it is subjected to dynamic loads from crowds or equipment. Steel props can be easily installed and adjusted to the required height, allowing for flexibility in accommodating different ground levels or seating arrangements. They are also durable and weather-resistant, making them suitable for outdoor sporting events that may face varying weather conditions. Moreover, steel props can be used in combination with other structural elements, such as scaffolding or bracing, to provide additional support and rigidity to the temporary sports field structures. This allows for the construction of larger and more complex structures, such as multi-tiered grandstands or elevated platforms. Overall, steel props are a reliable and versatile solution for supporting temporary sports field structures. They offer strength, adjustability, and durability, making them an essential component in ensuring the safety and stability of such structures during sporting events.

Send your message to us

Simple Single Side Bracket for Ten Level House Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches