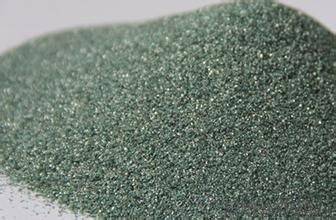

Raw Materials for Refractory:Silicon Carbide Black and Green

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Black SiC Specifications

Chemical Composition(%) | Chemical Composition(%) | Chemical Composition(%) | |

SiC | F.C | Fe2O3 | |

≥ | ≤ | ||

SiC99.5 | 99.3 | 0.20 | 0.14 |

SiC98.5 | 98.5 | 0.20 | 0.60 |

SiC98 | 98 | 0.30 | 0.80 |

SiC97 | 97 | 0.30 | 1.00 |

SiC95 | 95 | 0.40 | 1.00 |

SiC90 | 90 | 0.60 | 1.20 |

SiC70 | 70 | 3 | |

SiC65 | 65 | 5 | |

SiC60 | 60 | 10 | |

SiC55 | 55 | 10 | |

SiC50 | 50 | 10 | |

Green SiC powder specifications

Grade

| Size Distribution(µm) | Chemical Composition | |||||

D0 Max | D3 Max | D50 Median | D94 Min | SiC≥ | F·C≤ | Fe2O3≥ | |

#360 | 86.0 | 66.0 | 35.0±2.0 | 23.0 | 99.0 | 0.12 | 0.12 |

#400 | 75.0 | 58.0 | 30.0±2.0 | 20.0 | 99.0 | 0.12 | 0.12 |

#500 | 63.0 | 50.0 | 25.0±2.0 | 16.0 | 99.0 | 0.12 | 0.12 |

#600 | 53.0 | 43.0 | 20.0±1.5 | 13.0 | 98.90 | 0.13 | 0.13 |

#700 | 45.0 | 37.0 | 17.0±1.3 | 11.0 | 98.90 | 0.13 | 0.13 |

#800 | 38.0 | 31.0 | 14.0±1.0 | 9.0 | 98.80 | 0.14 | 0.14 |

#1000 | 32.0 | 27.0 | 11.5±1.0 | 7.0 | 98.80 | 0.14 | 0.14 |

#1200 | 27.0 | 23.0 | 9.5±0.8 | 5.5 | 98.80 | 0.14 | 0.14 |

#1500 | 23.0 | 20.0 | 8.0±0.6 | 4.5 | 98.70 | 0.15 | 0.15 |

#2000 | 19.0 | 17.0 | 6.7±0.6 | 4.0 | 98.70 | 0.15 | 0.15 |

#2500 | 16.0 | 14.0 | 5.5±0.5 | 3.0 | 98.70 | 0.17 | 0.17 |

#3000 | 13.0 | 11.0 | 4.0±0.5 | 2.0 | 99.30 | 0.03 | 0.03 |

#4000 | 11.0 | 8.0 | 3.0±0.4 | 1.3 | 99.30 | 0.03 | 0.03 |

#6000 | 8.0 | 5.0 | 2.0±0.4 | 0.8 | 99.30 | 0.03 | 0.03 |

#8000 | 6.0 | 3.5 | 1.2±0.3 | 0.6 | 99.30 | 0.03 | 0.03 |

#10000 | 4.0 | 1.2 | 0.6±0.1 | 99.30 | 0.03 | 0.03 | |

Our Services

1. Professional machine produce qualitied goods.

2. Professional worker gurantee finish production on time.

3. Professional transport term gurantee safe transport.

4. Professional sales team supply satisfied services.

Packaging & Delivery

Packaging Details: 25kg per small bag in jumbo bag or as customer's demand

Delivery Detail: Within 15 days after receipt of prepayment

Pictures

- Q: Urgent question: could you tell me that the export of refractory materials to Vietnam is to be packed in wooden cases and smoked?

- Strictly speaking, as long as there are solid wood packaging, you need to do fumigation inspection, proved not necessarily used, there are IPPC chapters on it.

- Q: What is the function of refractory material?

- Refractory is a basic material in the field of high temperature technology. Generally, the refractory is used as structural material or lining to resist high temperature in various thermal equipment and high temperature container. In the iron and steel industry and metallurgy industry, coke ovens are mainly composed of refractory materials. Various refractories that meet the requirements are essential in blast furnace for ironmaking, hot stove, all kinds of steel-making furnaces, soaking furnace and heating furnace. Not only the die casting for molten steel needs lots of refractory materials, but also the continuous casting needs some high-quality refractory materials. Without high-quality refractory materials, external refining is also not impossible to achieve. Statistics show that the steel industry is the sector that needs the most refractory. Pyrometallurgy and thermal processing of ferrous metal also needs refractories. All high-temperature furnaces or lining in construction materials industry or other high temperature industries that produce silicate products such as glass industry, cement industry, and ceramics industry must be constructed with refractory materials. All kinds of roasting funaces, sintering funaces, heating furnaces, boilers, flues, chimneys and protective layers in chemical, power and machinery manufacturing industry need refractories. In short, when some kind of structures, devices, equipments or vessels are used under high temperature, they all should utilize refractory to resist the high temperature because those materials will deform, soften and fuse or will be eroded, scoured or broken due to the physical, chemical, mechanical effects, which may stop the operation, affect the production, contaminate processed objects and impact the quality of products.

- Q: What's the difference between refractory metal raceway and fireproof raceway?

- Refractory metal is used to lay and control cables, while trunking is used to lay wires and communication cables; refractory metal is bigger (200*100-600*200), while trunking is smaller; refractory metal has bigger turning radius, while trunking mostly turns a right angle; refractory metal has larger span, while trunking has smaller span; their fixation and installation ways are also different.

- Q: What do we mean by saying that a ladle cover knots, elbow knots, blowpipe knots in refractory materials? What is the “knot”?

- A less accurate view of the statement is probably the meaning of the “construction of refractory material" , for example, pouring castable can be called “knot”, the pounding of the construction can also be said that, so it is with spraying paint.

- Q: Is the linear change on reheating the same as heating permanent linear change of refractory material?

- “+”represents expansion. the afterexpansion and aftercontraction after cooled to be at room temperature. The change may significantly damage the masonry of thermal kiln. There are regulations on the linear change on reheating of common refractory material in the national standard. Some physical chemical changes may continue. It is defined as the change from being heated to the specified temperature of refractory material sample. Heat preserving for a while till afte cooling to be at room temperature, then the residual will expand or contract in its length, heat preservation for a while, organization vitrification, the irreversible changes of its length refers to heating the firing refractory to be at high temperature, so as to make the volume of refractory materials expand or contract, due to the influence of uneven temperature or lack of time, otherwise it will cause the deformation of the refractory ball and make this indicator within standard even reach smaller value, so firing control must be strengthened in product production. But it is should not be too high. For refractory materials with same chemical composition, the linear change on reheating is produced in the heating process. Properly increasing sintering temperature and prolonging the holding time is an effective process measures, make its firing inadequate. When subjected to high temperature, it can reduce the thermal shock resistance. Minus sign "-" represents contraction. The permanent line rate refers to heating the fire refractory ball to the specified temperature. Linear change on reheating, also known as residual linear change, is an important indicator to assess the quality of refractory in the long time use. To control the permanent line rate within the standard or reach the minimum value.

- Q: Who can introduce the external wall thermal insulation materials fire rating regulations?

- According to public fire-fighting [2007] No. 182, the contents of the notification on the implementation of a number of issues of national standards GB8624-2006 "building materials and products combustion performance classification", since there is large differences between the new version of the standard GB8624-2006 and the old version of GB8624-1997 in the principle, hierarchical structure and test methods. According to the cintent of notification, in order to ensure a smooth transition between the old and new standards, the current national standard "Fireproof? Specification of Building Interior Decoration?Design" GB50222, "fire?safety?rules of tall civil buildings design" GB50045, "Fireproof? Specification of Building Design" GB50016 have not completed the relevant amendments, the new classification method of GB8624-1997 and GB8624-2006 can be used for temporary reference in terms of combustion performance of materials . From GB8624-2006 standard implementation, the classification of combustion performance is too granular, which do not match to the actual construction of the current project in our country. Therefore, the relevant departments carry on the 3rd amendment for the GB8624-2006 standards, namely GB8624-2012, and it will be released on December 31, 2012 and implemented on October 1, 2013. The combustion grading requirements in the standard: Level A is non-combustible materials (products); level B1 is nonflammable material (products); level B2 is combustible materials (products); level B3 is flammable materials (products).

- Q: What substitutes are available for high-end refractories in addition to zircon sand?

- If you want to use environmentally friendly products, please use recycled Mo powder.

- Q: Which kind of external wall fire barrier zone material is better?

- The following types are: rock wool, aerated concrete, phenolic aldehyde and foam cement rock wool fire barrier zone "rock wool board" mainly uses water-repelling rock wool board produced by pendulum method as thermal insulation layer materia, and connecting and fixing base wall by binding and nail bonding, it is composed level A non-combustible building energy efficiency thermal insulation system by plastering layer composed by plastering mortar and glass?fiber mesh and decorative mortar finishing layer or coating. Good air permeability

- Q: Does refractory belong to metallurgical auxiliary materials?

- Refractory includes metallurgical auxiliary materials.

- Q: What are the advantages of refractory material?

- Jingute WHL type, GDS type

Send your message to us

Raw Materials for Refractory:Silicon Carbide Black and Green

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords