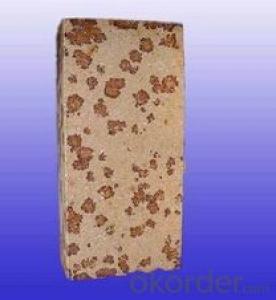

Silica Bricks for Industrial Glass Furnaces

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

It is the ideal materials , glass smelting furnace and other industrial thermal kilns.

The products are possessed of the following characteristics: stable quality, small overall dimension tolerance, high softening temperature by loading, small true density, few quartz residue, etc. It wins appreciation and compliments from the customers as home and abroad. Through the examination of the refractory material quality inspecting center of state, the physical and chemical index of this product reaches or surpasses international standard; this product has passed ISO9000 quality system authentication. It is the ideal materials , glass smelting furnace and other industrial thermal kilns.

Technical data

Silica brick for glass furnace | |||||||

Item: | GF-96A | GF-96B | GF-95A | GF-95B | |||

SiO 2 | ≥96 | ≥96 | ≥95 | ≥95 | |||

Fe 2 O 3 | ≤0.8 | ≤1.0 | ≤1.2 | ≤1.2 | |||

Apparent porosity % | ≤22(24) | ||||||

Cold Crushing Strength MPa | Brick below20KG | ≥35(30) | |||||

Brick ≥20KG | ≥30(25) | ||||||

Refractoriness under load ºC | ≥1680 | ≥1670 | ≥1660 | ≥1650 | |||

True density g/cm ³ | ≤2.34 | ≤2.34 | ≤2.35 | ≤2.35 | |||

Silica brick for coke oven | |||||||

Item: | CO-94A | CO-94B | |||||

SiO2: % | ≥94 | ≥94 | |||||

Al 2 O 3 : % | ≤ 1.5 | ≤ 1.5 | |||||

Fe2O3: % | ≤ 1.5 | ≤ 1.5 | |||||

Refractoriness under load 0.2Mpa | ≥ 1650ºC | ≥ 1650ºC | |||||

Apparent porosity: % | ≤ 22 | ≤ 24 | |||||

Bulk density: g/cm ³ | ≤ 2.34 | ≤ 2.35 | |||||

Cold crushing strength: MPa | ≥30 | ≥25 | |||||

Permanent linear change % (1450ºC ×2h) | 0~0.2 | 0~0.2 | |||||

Thermal expansion(1000ºC) | ≤1.28 | ≤1.30 | |||||

Silica brick for hot blast furnace | |||||||

- Q: The introduction of silica brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Different insulation methods can be adopted according to the length of the stop time and the location and equipment of the overhaul. Gold, refractory material factory specializing in the production of various specifications of brick

- Q: The difference between clay refractory bricks and refractory brick in the application.

- The ability of alkali resistance is poor, the thermal shock stability is the worst, and it is scrapped at one time. The brick is generally used in the coke oven, glass kiln. Other industries basically do not use.

- Q: Semisilica brick interpretation

- Good thermal shock resistance. In use, more high viscosity glass phase can be formed, and the masonry brick joint and the working surface are dense and the masonry is complete, which is beneficial to improve the impermeability of the masonry and reduce the erosion effect of the slag on the masonry.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into phosphorus and quartz. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: The brick is mainly used in the place?

- Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- The scale quartz is a spear shaped double crystal structure, very compact and favorable to the increase of thermal conductivity. The high thermal conductivity of silica brick in improving thermal conductivity and other performance indicators and traditional coke silicabrick agreement.That is to say, the high thermal conductivity of silica brick all inherited the traditional advantages of coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: What are the main constituents of refractory bricks?

- Clay brick and clay brick are mainly composed of mullite (25% ~ 50%), glass phase (25% ~ 60%) and square quartz and quartz (up to 30%). Usually with hard clay as raw material, pre calcined mature material, and then with soft clay, semi dry or plastic molding, the temperature at 1300~1400 C fired clay brick products. Can also be added a small amount of water, glass, cement and other binders to make non burning products and amorphous materials. It is a refractory brick commonly used in blast furnaces, hot blast furnaces, heating furnaces, power boilers, lime kilns, rotary kilns, ceramics and refractory bricks.

- Q: Such purpose and scope please give me detailed points thank you

- Mainly used for coke oven carbonization chamber and the combustion chamber wall, open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace, refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

Send your message to us

Silica Bricks for Industrial Glass Furnaces

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords