Silica Brick for Furnace Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

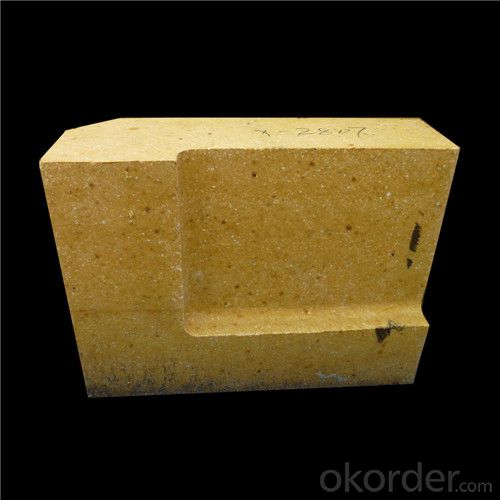

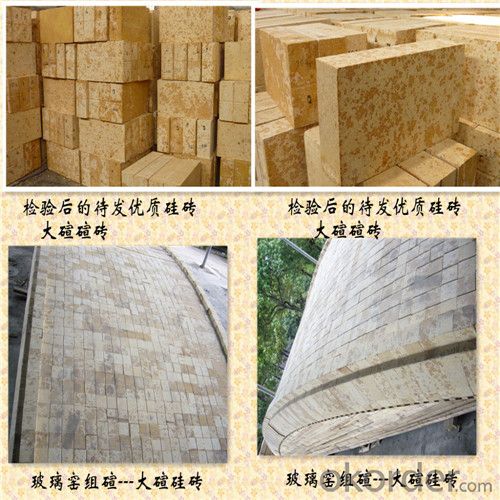

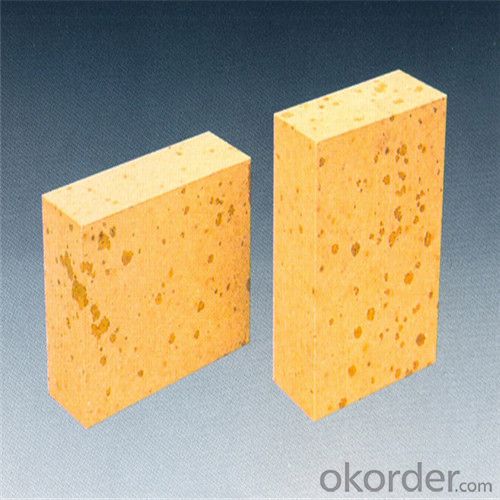

With dense and smooth appearance, uniform corner and edge, pure color and luster and accurate size

1)Silicon oxide is above 95%.

2) Good acid erosion resistance.

3) High softening point with temperature.

4) No shrink in burn repeatedly.

5) Temperature of refractoriness under load is above 1650º C

Stable Capability, High Quality, Excellent Service, Competitive price is the most important advantage of our products

Item | BG-94 | BG-95 | BG-96A | BG-96B | |

Chemical composition | SiO2 | ≥94 | ≥95 | ≥96 | ≥96 |

Fe2O3 | ≤1.5 | ≤1.5 | ≤0.8 | ≤0.7 | |

Al2O3+TiO2+R2O | ≤1.0 | ≤0.5 | ≤0.7 | ||

Refractoriness °C | 1710 | 1710 | 1710 | 1710 | |

Apparent Porosity% | ≤22 | ≤21 | ≤22 | ≤22 | |

Bulk Density g/cm3 | ≥1.8 | ≥1.8 | ≥1.8 | ≥1.8 | |

True Density,g/cm3 | ≤2.38 | ≤2.38 | ≤2.34 | ≤2.34 | |

Cold Crushing Strength Mpa | ≥24.5 | ≥29.4 | ≥35 | ≥35 | |

0.2Mpa Refractoriness Under Load T0.6 °C | ≥1630 | ≥1650 | ≥1680 | ≥1680 | |

Permanent Linear Change On Reheating (%)1500°CX2h | 0~+0.3 | 0~+0.3 | 0~+0.3 | 0~+0.3 | |

20-1000°C Thermal Expansich10-6/°C | 1.25 | 1.25 | 1.25 | 1.25 | |

Thermal Conductivity (W/MK) 1000°C | 1.74 | 1.74 | 1.44 | 1.44 | |

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

- Q: The introduction of silica brick

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature.

- Q: Physical solid waste disposal

- Reduce crack production and improve yield. The amount of addition is related to the shape and weight of the brick. The bricks can be added to 20% weight less than 25kg; bricks above 25kg can be added to 30%; for the specific type of brick can be added 30%. into waste silica brick should pay attention to this problem

- Q: The specific content is what gb/t2608-2012 brick

- The provisions of the brick classification, technical requirements, test methods,

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- Small fluctuations in the chemical composition do not have a significant effect on use. The key is the operation of the electrolyzer in production to determine whether the side wall will be damaged.

- Q: The brick is mainly used in the place?

- Partitions used in coking and combustion chambers for coke ovens

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Brick, high thermal conductivity has been greatly improved in terms of morphology, crystal structure, physicochemical index. The structure and morphology of high thermal conductivity of silica brick,Structure and morphology of high thermal conductivity and the traditional brick brick magnified 20 times were compared, high thermal conductivity silica pore size distribution is more uniform and finer.

- Q: What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon, aluminum, clay and so on:

- Q: Why in the production of the brick to detect the volume density

- Product quality control of silica brick.

- Q: Such purpose and scope please give me detailed points thank you

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

Send your message to us

Silica Brick for Furnace Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords