Silica Brick - Acid-Resistant / Proof Refractories

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

Refractory Acid-resistant brick is the main refractory materials of steel processing system cold-rolled sheet,

silicon steel line, etc. used for acid reproduction baking furnace, and its performance will directly

affect the service life and economic benefits of acid reproduction baking furnace.

It is used as working lining for anti erosion and acid proof pickling groove,acid storage tank,leaching tower,anti-erosion and acid proof floor,tubes and etc, Except hydrofluoric acid as the medium in chemical, petroleum, metallurgic, smelt, electric power, fertilizer, fiber, pharmacy, and alkaline system industries.

Applications

The reaction boilers, columns & tanks.

Mixing pools

Acid-resistant walls in non-ferrous metal industry

Acid-resistant structures in chemical industry.

Feature

1.Good acid resistance

2.High compression strength

3.Good abrasion resistance

4.Good corrosion resistance

Technical Data

| Bulk Density | (g/cm3) | 2.21-2.24 |

|---|---|---|

| Pore Ratio | (%) | 9.3-10.5 |

| Water Absorption Ration | (%) | 4.2-4.7 |

| Modulus of Elasticity | (mpa) | 2138 |

| Compressive Strength | (mpa) | 123 |

| Acid Resistance Degree | (%) | 99.8 |

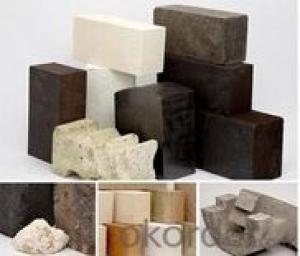

Photos for Workshop

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Different insulation methods can be adopted according to the length of the stop time and the location and equipment of the overhaul. Gold, refractory material factory specializing in the production of various specifications of brick

- Q: The specific content is what gb/t2608-2012 brick

- Quality assessment procedures, packaging, marking, transport, storage, and quality certificates. Suitable for siliceous refractory bricks.

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- Small fluctuations in the chemical composition do not have a significant effect on use. The key is the operation of the electrolyzer in production to determine whether the side wall will be damaged.

- Q: How much is the highest melting point of silicon?

- Acidic silica brick refractories, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature. More than 94% silica content.

- Q: Can iron oxide be used as refractory material?

- Iron oxide can not be used as refractory material, but it can be used as refractory additive. Iron oxide can be used as pigment

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- To improve the thermal conductivity of silica brick for coke oven rate method:Manufacture of high density and high thermal conductivity of silica brick, adding additives such as CuO, Cu2O, TiO2, Fe2O3, (FeO), can improve the thermal conductivity of silica brick.

- Q: What is the silica refractory products?

- Refractory brick with silica content greater than 90%.

- Q: Why in the production of the brick to detect the volume density

- Fast density test, please consult an instrument.

- Q: The formula in the refractory brick, and firing curve, who knows?

- Add 1.8-2.2% of the total weight of the main raw material, and then add lime milk, rolling for 10-15 minutes, and finally add pulp, rolling for 10-15 minutes, out of the mill, forming billet.

Send your message to us

Silica Brick - Acid-Resistant / Proof Refractories

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords