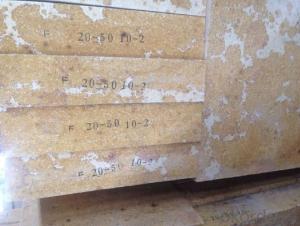

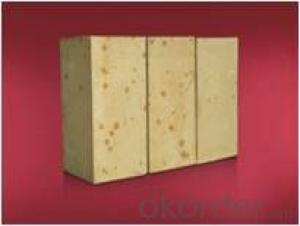

Silica Brick - Refractory Acid Resistance for Furnace Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

The silica brick can be widely used in coke oven, hot blast furnace, glass furnace and carbon furnace. In glass industry, it is mainly employed to build the doghouse crown, suspended wall of channel, top crown and inlet sealing. In metallurgy industry, it is adopted as the nozzle brick

Features

1.High purity

2.Long service life

3.Accurate size tolerance

4.Pure color

5. Luster appearance

6..Good thermal conductivity

7.Good creep resistance

Application of the Acid refractory silica bricks

The refractory silica bricks are primarily used for furnaces and kilns in the field of metallurgy, steel, power, chemical industry, and electric power and machine building etc.

Physical & chemical indexes of the Acid refractory silica bricks

Item | Unit | BGZ-65 |

SiO2 | % | ≥65 |

Al2O3 | % | ≤30 |

K2O+Na2O | % | ≤1.0 |

Permanent linear Change(1350°C×2h) | % | ±0.2 |

Apparent porosity | % | ≤24 |

Cold crushing strength | Mpa | ≥25 |

Refractoriness under load, 0.2MPa | °C | ≥1350 |

- Q: Why will expand when heated brick

- After high temperature after the formation of tridymite and cristobalite and quartz and a small amount of residual glass phase, quartz heating to 220-240 DEG C, in a certain degree of thermal expansion, brick maximum expansion occurs in 100~300 DEG C, 300 expansion before the total amount of expansion is about 70%~75%.

- Q: The introduction of silica brick

- The characteristics of silica brick:Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.The use of silica brick:Mainly used for masonry brick oven carbonization chamber, a combustion chamber and a partition wall, glass furnace and kiln roof, pool wall, high temperature hot blast furnace, glass furnace, load-bearing pool wall, hot blast stove, baking furnace of carbon bearing part of high temperature furnaces etc.. Rongsheng with refractory

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick with silicon oxide content, low melt index, mainly used for glass kiln crown, parapet, wall hanging, small furnace arch superstructure and regenerator.

- Q: Which material is good for furnace refractory?

- Basic refractories in Magnesium Oxide and calcium oxide as the main ingredient, commonly used is brick. Magnesium Oxide 80% to more than 85% containing magnesia brick, has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio. Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and high temperature equipment.

- Q: The United States of our brick anti-dumping duties?

- . According to the relevant legal procedures, the United States International Trade Commission will make a final ruling on the anti dumping industrial injury before January 6, 2014, if an affirmative determination, the U.S. Department of Commerce will be involved in product release tax anti-dumping order.

- Q: Can iron oxide be used as refractory material?

- Iron oxide can not be used as refractory material, but it can be used as refractory additive. Iron oxide can be used as pigment

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Brick, high thermal conductivity has been greatly improved in terms of morphology, crystal structure, physicochemical index. The structure and morphology of high thermal conductivity of silica brick,Structure and morphology of high thermal conductivity and the traditional brick brick magnified 20 times were compared, high thermal conductivity silica pore size distribution is more uniform and finer.

- Q: What is the silica refractory products?

- High silicon content in high temperature expansion sintering temperature between 1390-1410 in furnace arch

- Q: High temperature refractory material?

- Special materials often use AZS brick (i.e. corundum brick), corundum brick, magnesia chrome bricks, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Insulation refractories are often used diatomite products, asbestos products, insulation board. Unshaped refractories are often used refractory castable, refractory clay, refractory ramming material, refractory plastic and fettling material, fire resistance, gunning, refractory cast material, fireproof coating, lightweight refractory castable, gun mud.

- Q: The formula in the refractory brick, and firing curve, who knows?

- Add 1.8-2.2% of the total weight of the main raw material, and then add lime milk, rolling for 10-15 minutes, and finally add pulp, rolling for 10-15 minutes, out of the mill, forming billet.

Send your message to us

Silica Brick - Refractory Acid Resistance for Furnace Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords