short width and small roll pp spunbond non woven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

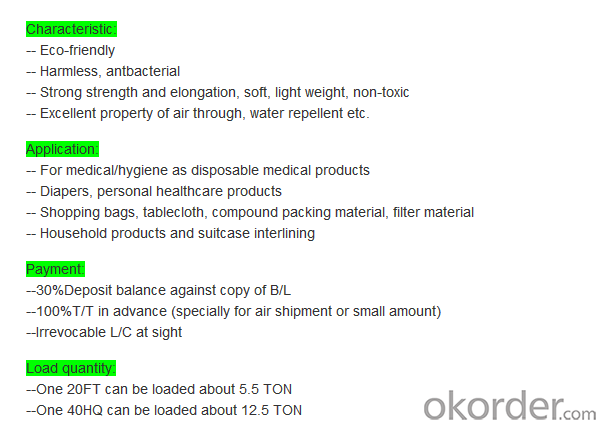

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

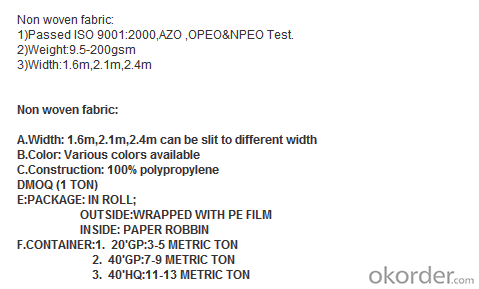

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: How can paint points be removed during textile processing?

- Paint itself is not binding on the textile, are relying on cross-linking agent, adhesive to fix.

- Q: What is the amount of alkali in the textile mill

- Silk is the softest and most breathable raw material for all textile materials. The polyester is a synthetic fiber, non-hygroscopic, airtight, feel rough

- Q: What is the textile technology profession now?

- Knitting process; This course introduces the basic concepts of knitting and knitwear, weft knitting and warp knitting machine basic structure and working principle, commonly used knitted fabric weaving methods and process analysis

- Q: What is a large circular machine and a small circular machine in the textile?

- Second, the large circular machine also has low-grade products, small round machine also has quality products. Brand knitting circular machine is in the high-end products, the size of the specifications are, and the name of the assembly of the knitting machine is also the size of the size of the specifications, but its performance, function and accuracy is far better than the brand machine.

- Q: DTY FDY POY What are the textile raw materials?

- FDY: full stretch silk. Full name: FULL DRAW YARN. The synthetic filament filaments were further prepared by spinning. The fibers have been fully stretched and can be used directly for textile processing.

- Q: What are the classification of the textile?

- Weft yarn, weft yarn, weft density - fabric width direction; the yarn is called weft yarn, the number of yarns in 1 inch is the weft density (weft density)

- Q: What are the raw materials for textiles?

- You can wall wall (tapestry), not afraid of the fire and the fire (asbestos cloth, fire clothes). Like Weng woman to Tong Yan (actor dressing veil), really for the soldiers to add wings (parachute). Can protect the rocket head (aramid fiber fabric), can be used for bulletproof clothing. Enough to filter (functional fiber), where fear of electric shock (live operation taking the pressure of silk). Beauty Kam, embroidery (embroidery), odd with tapestry.

- Q: How does the chemical composition of the textile be analyzed?

- PH value, formaldehyde content, lead content, azo dye test, heavy metal content test, water absorption, moisture content, odor, cotton mercerizing effect, hot pressing, dry heat, storage sublimation, acid spots, Spots, phenolic yellowing and so on.

- Q: What is the difference between the mesh pattern on the textile structure?

- As the chemical fiber has its own characteristics, are generally blended. Such as adding a certain percentage of natural fibers (wool, cotton, silk, linen), or different chemical fiber blends, take their own characteristics, get fine fabrics. Chemical fiber in the proportion of clothing is more polyester.

- Q: What are the products produced by the textile mill?

- From the processing of the process, said: basically the fiber - yarn - line - cloth. Yarn is divided into weaving yarn, knitting yarn. Chemical fiber yarn is sprayed with spinneret. Cloth is divided into woven fabrics, knitted fabrics, finished dyeing and finishing yarn weaving and so on.

Send your message to us

short width and small roll pp spunbond non woven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords