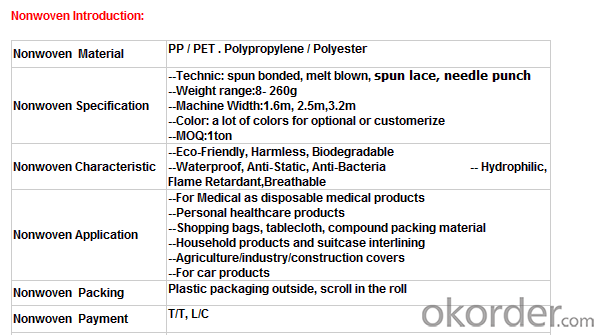

PP Spunbonded Nonwoven Fabric in Rolls, PP Spunbonded Non-Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

Nonwoven Advantage:

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q: Lin is what kind of textile

- For jacquard fabric, can not be hard brush scrubbing, to prevent yarn breakage. 3, cotton fabric with good physical and chemical properties, but also should not be soaked in the washing solution for too long, exposure time can not be too long to prevent the destruction of color. 4, cotton fabric easy to float color, washing to prevent string dyeing and pick color, affecting the fabric appearance.

- Q: What is the anti-perspiration finishing of textiles?

- Anti-perspiration finishing of textiles and we often say that the perspiration fastness is completely different concept, the anti-perspiration finishing of textiles in the printing and dyeing plant on the side of the fabric side of the hydrophilic side of the waterproof processing

- Q: What is the meaning of TOP in the textile industry?

- Polar fleece is generally the case, towel cloth fabric - dyeing - grasping hair - pull hair - cut hair - shake tablets - stereotypes ordinary double-sided cloth are generally stained + stereotypes, double-sided type too much.

- Q: Textile machine, I should use single-phase power or three-phase electricity

- Single-phase power production capacity must be almost, the security of the above words, the individual is much better, but the power to increase a little

- Q: Textile finishing TPU, TPEF film. What's the difference?

- TPU cold resistance: TPU glass transition temperature is relatively low, at minus 35 degrees still maintain good flexibility, flexibility and other physical properties.

- Q: Is there a large yarn factory or a textile garment factory?

- Textile: the subject is too large, including textile raw materials production, spinning, weaving, printing and dyeing, finishing, and then into the clothing link.

- Q: How does the chemical composition of the textile be analyzed?

- The chemical composition of a substance refers to the proportion of each chemical element, expressed in experimental form

- Q: Do you need to do environmental protection for dry textile processing?

- Family business is to all the property owned by the family, personal business is funded by the individual property.

- Q: What causes the loss of textile enterprises

- Roughly three points, each of the textile industry has its own characteristics, including the cost, including sales channels

- Q: What is the use of polyurethane TPU hot melt adhesives in textiles?

- Carpet rubber adhesive with the basic material for the ethylene and other olefinic monomer copolymer, such as ethylene - vinyl acetate copolymer, ethylene acrylate copolymer. The vast majority of cases are the use of ethylene. Vinyl acetate copolymer (EvA).

Send your message to us

PP Spunbonded Nonwoven Fabric in Rolls, PP Spunbonded Non-Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches