SG2 Carbon Steel Welding Wire ER70S-6

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Tons m.t.

- Supply Capability:

- 20 Tons per Week m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SG2 Carbon Steel Welding Wire ER70S-6

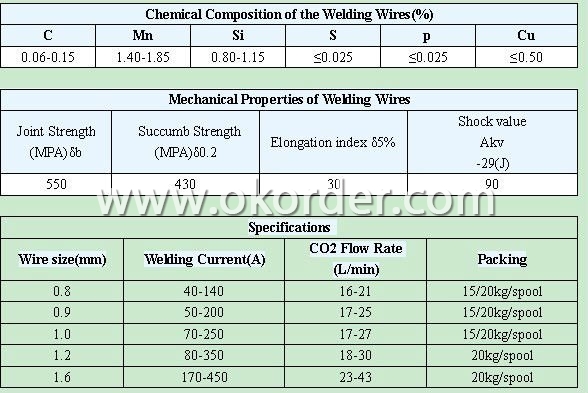

Material: copper coated carbon steel

Wire dia: 0.8/0.9/1.0/1.2/1.6mm

Packing: 15/20kgs/plastic spool/box, 72boxes/pallet

er70s-6 welding wire/ copper welding wire

1.Material:copper coated carbon steel

2.Wire diameter:0.8/0.9/1./1.2/1.6mm

3.Packing:15/20kgs/plastic spool/box, 72boxes/pallet.

4.Usage:

welding wire has excellent mechanical performance such as depositing speed and high efficiency, stable arc, little splash , good welding seam, strong resistance to surface scales and oil stains on the base metal, mainly used for welding low carbon alloy steel, industries of vehicles, bridge-engineering, machine-engineering, steel structures, shipping manufacture.

5.specification

- Q: Or welding door flower (parts) are generally much better at the factory with a welding wire of 1 mm or 0.8 mm wire is not well below the welding wire 0.8 wire is how much I used 0.8 small wire welding wire than in other plant good welding is much wire. Thank you!!!

- 0.6, it is difficult to weld again.

- Q: I would like to register the trading company, agent wire, I would like to know in the industrial and commercial registration of wire and wire, what kind of business scope is belonging to?

- Hello, if there is interest in partnership with open trading company, I also do consumables sales

- Q: What kind of wire is ER80S-G and what material is it mainly welded to?

- Carbon steel or low-alloy steel of 550MPa strength

- Q: Why is welding wire plated copper?

- Mainly to improve the conductivity of welding wire

- Q: What does "GHS-70" wire mean?

- High strength steel wire, tensile strength 630MPa.

- Q: What kind of gas shielded welding wire for Q345 steel plate?

- Carbon steel welding wire for Q345 steel using ER50-6 gas shielded welding.ER50-6 is a kind of carbon steel welding wire for gas shielded welding. It has excellent plasticity, toughness and crack resistance, especially low temperature impact toughness.Application: it can be used in various positions of pipes such as manual tungsten inert gas arc welding, grounding and arc welding, and satisfactory welding joints can be obtained. Weldable carbon steels and certain low alloy steels.

- Q: What type of welding wire should be used to weld cast iron parts with carbon dioxide gas shielded welding?

- Carbon dioxide gas shielded welding non welding cast iron.Carbon dioxide welding wire models.JY50-6 with GB/T8110-1995 (ER50-6) CO2 gas shielded arc welding is suitable for low carbon steel and low alloy steel in AWS ER70S-6.JY50-6 welding, especially suitable for vehicles, containers, engineering machinery, pressure vessel welding jie. JY-308 with GB/ T17854-1999 (H0Cr21Ni10), AWS ER308, JIS Y308. is equivalent to JY-308 for tungsten argon arc welding of stainless steel wire for welding of Cr18Ni8 stainless steel, chemical industry, petroleum equipment, little spatter, weld appearance. JY49-1 (H08Mn2SiA) conforms to GB/T8110-1995 (ER49-1) JY49-1 welding wire, suitable for low carbon steel and low alloy steel CO2 welding, such as construction machinery, bridges, vehicles, pressure vessels and other welding. JY44-8 (I) conforms to TB/T2374-1999 (H08MnSiCuCrNi I), and is suitable for weathering steel welding in railway rolling stock and automobile manufacturing industry.Welding wire specification: 1.0mm Cu. 1.2mm 1.6mm welding wire type "I" means carbon dioxide welding wire model of "8" means that the welding wire containsCarbon dioxide shielded welding wire, welding H08MnSiA welding wire for low carbon steel,H08Mn2S welding wire for welding low alloy steel,The utility model has the advantages of low cost, high production efficiency, good operation, good welding quality, etc.;Choose the appropriate welding wire, mainly to prevent spatter and affect quality, the landlord can choose as neededThe remaining flux cored wire is classified as EF-1 DC, single pass weldingEF-2 DC, single pass weldingEF-3: direct current, single pass soldering, except for core components and EF-1

- Q: What is welding wire? How to translate welding wire?

- Welding, also known as solder wire, the use of electric iron melting wire, tin solder cooling, you can complete the welding

- Q: CO2 protection wire, which brand of domestic quality is good?!In addition to the Atlantic and the Golden Bridge, and the brand of excellent quality?

- Our factory is used in Tianjin Jinqiao, the quality of products should be good, the price is relatively high, but the brand trustworthy

- Q: I am the manufacturer of stainless steel welding wire, and I have been asked by the customer - stainless steel wire outlet customs code. I do not know, please know the friend told me, I will be very grateful.

- HS coding export name, measurement unit, tax rate, tax rebate rate, starting date, expiry date, consumption tax rate, regulatory conditions7326201000 industrial iron and steel products, kg 17, 5, 2007-07-01, 2100-12-31, none

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | South America Southeast Asia Africa Mid East Eastern Asia South Asia |

| Company Certifications | ISO 9001:2000;ISO 9001:2008;ISO 17799 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | XINGANG |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

SG2 Carbon Steel Welding Wire ER70S-6

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Tons m.t.

- Supply Capability:

- 20 Tons per Week m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords