Sewage Sucking Truck 14m3 SINOTRUK 4x2 QDZ5250GXWZ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description for QDZ5250GXWZ

Place of Origin: Shandong, China (Mainland)

Model Number: QDZ5250GXWZ

Features for QDZ5250GXWZ

This sewage suction truck is mainly used to suck, transport, unload, and load sewage and sludge existing in the sewer lines and rainwater wells, and it can also be used to suck and transport wastewater, industrial waste oil, and sewage in large factories. Furthermore, sometimes it can even be used to dredge and clean small watercourses.

It is mainly composed of chassis, tank, hydraulic system, high-pressure system, and electrical system.

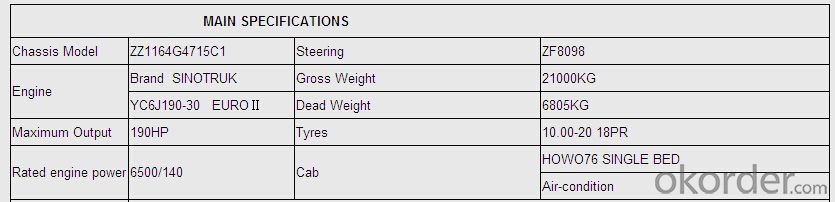

Specification for QDZ5250GXWZ

Pictures for QDZ5250GXWZ

MOQ for QDZ5250GXWZ

Q:What is the advantages of this type of sewage suction truck?

A:Sewage suction truck installs force taking device, transmission shaft, vacuum pump, pressure tank,

hydraulic parts, pipe network system, and equipped with a vacuum pressure gauge,dung window (pipe) device.

9meter long 360 degree swivel suction tube,Hangzhou Weilong vacuum

double pump,model:68/7000,with the anti overflow valve, oil and gas separator, moisture separator, four

way valve.Tank head is 6mm,body size: length 7080mm* macro axis 2400 mm* minor axis1620 mm,four partition boards,

turtle heads,rear head with a 6 Inch disc valve excrement outlet.

- Q: What is the meaning of the word "concrete" in the concrete mixer jar?

- In a large number of academic articles, the use of "concrete" is frequently used. In an academic seminar, the concrete was officially replaced with concrete. The "concrete" reads "TONG". Bituminous concrete meaning of commercial concrete, certain mixing station at the time of order mixers to manufacturers on their own brand, for instance the mixers in dacheng mixing station tanks on "dacheng bituminous concrete. If it is a part of nanjing city, it can also be printed on the tank. This is not a very demanding, different person.

- Q: How many layers of steel wire tyres are used in concrete mixers

- For example; 1200 the r20 pr M588 18 1200 is the outer circle size R is the radial tire 20 is the inner circle size, Should be 18PR!!!!!! This is the level of the wire in the tyre. M588 is the symbol of tire tire!! Concrete agitator truck tyres are usually used in 18 levels of steel wire tyres, which is used in 20 levels I'm selling tyres, I hope to help you

- Q: What is the normal speed in the transportation of the concrete mixer

- 1 to 3 RPM for transportation Normal 0 -- 6 is all right

- Q: Is it possible to mix the concrete in a mixing truck for eight hours?

- The concrete was stirred in the blender truck for eight hours and if it was added, there was no problem. In the case of not add water to let out a bit to see, if haven't lost the plastic concrete, slump of qualified, can continue to use, otherwise, had to be abandoned, or as aggregate, points repeatedly to stir.

- Q: What is the car for concrete

- It is called mixer truck concrete mixer truck There are also some people called muck mixer truck

- Q: Is a tanker and a mixer a thing

- The tank car is packed with concrete, only for short distance transportation. The mixer can be carried by water and can be transported over long distances

- Q: What are the three main parts of the concrete mixer car

- Oil pump, motor, speed reducer... Please do not hesitate to adopt

- Q: How did the concrete agitate the concrete

- Is not fully mixing concrete concrete truck mixer, concrete mixing transporter in the moving process of mixing is just to prevent tank (concrete mixer truck loaded tank is provided by the ready-mixed concrete mixing station) concrete segregation phenomenon.

- Q: What is the driving license for a concrete mixer truck?

- It requires a B2 photo, and the corresponding driving model is a large van. Heavy-duty, medium sized special operations vehicle, quasi-driving and code name:

- Q: What can be done to remove the concrete from the concrete mixer truck

- It consists mainly of agitator and auxiliary supporting parts. Mixing drum of concrete loading container, it is made from high quality wear-resistant steel sheet, in order to be able to automatic loading and unloading of concrete, the lining welding spiral blade with special shape. When the concrete moves in the direction of the blades, it is mixed and stirred in the process of increasing and turning. In the process of feeding and transportation, the mixing cylinder is turning, the concrete is moving in the blade, and the mixing cylinder is turned and the concrete is removed out of the blade. The rotation of the mixer is guaranteed by the hydraulic actuator. The load is 3-6 cubic meters. Of commonly used concrete mixer truck passed by the car engine power output shaft to drive hydraulic pump, and driven by hydraulic motor with high pressure oil push the mixing barrel, loading capacity for 9 ~ 12 cubic are driven by automotive auxiliary diesel engine driven hydraulic pump hydraulic motor. The blades are the main parts of the mixing plant, and the damage or severe wear and tear can cause the concrete to be mixed. In addition, if the design is unreasonable, the concrete will be isolated.

Send your message to us

Sewage Sucking Truck 14m3 SINOTRUK 4x2 QDZ5250GXWZ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches