Lifting Tank Semi Trailer with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

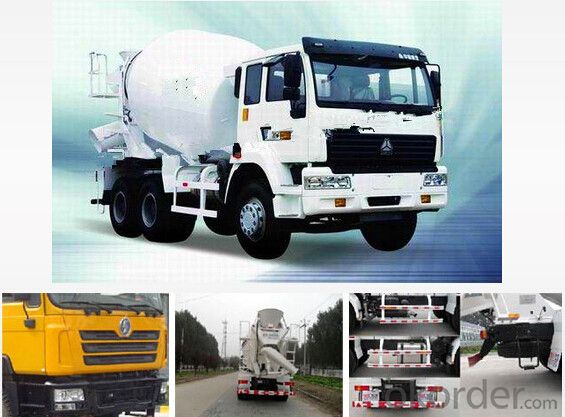

Product Name: Lifting Tank Semi Trailer with Good Quality

1. Specification

Overall size (mm) | 12990(L)*2500(W)*3960 (H) |

Wheel base (mm) | 6900+1310+1310 |

Tread (mm) | 1840 |

Kerb mass(Kg) | 10000 |

Min. turning diameter(m) | 20 |

Min. ground clearance | 360 |

Main configuration parameters | |

Axles | BPW 14T��3 axles |

Towing pin | Jost brand, 50mm or 90mm |

suspension | Leaf spring suspension or air suspension |

tyre | 12R22.5, 12+1 |

Brake system | dual circuit, drum brake, air drive with ABS |

ABS | 4S/2M |

Tank body parameter | |

Tank actual volume��m3�� | 55 |

Tank actual dimension(mm) | 12150*2500*2300 |

Maximum lift angle(��) | 46 |

Unloading speed | More than or equal to 1.2m3/min |

Discharge residue rate | Zero(less than 20KG) |

Tank material | Aluminum alloy, optional for stainless steel |

Tank mouth | One compartment and four tank mouth |

Air supply | External source |

2. Application

Cement Container and delivery.

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce Lifting Tank Semi Trailer with Good Quality according to customers request?

A4: Yes, we can produce Lifting Tank Semi Trailer with Good Quality according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q: What is the normal speed in the transportation of the concrete mixer

- 12 square concrete mixer, 6 * 4 maximum wheelbase can be installed 12 square 14 square, must use 8 * 4 chassis (don't want to type to copy a bit!) ! Note: 1, the mixer has a low gear, and the novice should pay attention. No more than 30 yards for the car turning. The car itself is in control. 3, pay attention to the car. You must get out of your car to see the road, otherwise you will be miserable. 4, 24 hours to the sleepy at night, but must put the material to the site after finishing Can have a rest. On the way or captain will drive to you ha ha! I am ~, Other things like the road should be familiar, the road is the most important.

- Q: How many years does the concrete agitator truck go away?

- Depending on how you use it, it doesn't matter if you take care of it for more than a decade

- Q: The concrete mixer transporter is running continuously for no more than one hour

- The concrete mixer transporter is running for no more than 8 hours. Concrete mixing is divided into two kinds: artificial mixing and mechanical stirring Manual stirring search When stirring, try to be quick, stirring time from adding water, should meet the following rules in general: The volume of the mixture is 4 ~ 5min (minute) under 30L. The volume of the mixture is 30L - 50L at 5-9min The volume of the mixture is 51L - 75L at 9 ~ 12min After mixing, it is required to do the slump measurement or the specimen forming according to the test requirement. The total operation must be completed in 30min from the beginning of the addition of water.Mechanical agitation First, it is the first batch, which is to make the ripper first, so as not to affect the mixing ratio of the mix. Start the mixer, blender, in turn, to join the gravel, sand and cement, stir evenly, add the water slowly again, all charging time not more than 2 min, water after all to join, to continue mixing 2 min.

- Q: How does the concrete mixing truck work?

- Working principle is that by taking power device to take out car chassis power, and drive hydraulic system of the variable pump, the mechanical energy into hydraulic energy to quantitative motor, motor and drive reducer, driven by speed reducer mixing plant, for mixing concrete

- Q: s the collapse of four concrete mixer trucks

- Do you mean the concrete can be transported by the concrete mixer? If that's the case, then I say clearly, no, it's a problem that the slump is put in and out of the car. The average slump is 100 to 120mm, and it is better not to transport the concrete transporter, and the best way to do it is to search for it.

- Q: What are the three main parts of the concrete mixer car

- The speed reducer, the pump radiator, is to make the mixing tank turn

- Q: How did the concrete agitate the concrete

- By rotating the concrete from the tank through a turbine fan, it can control the gears to adjust the speed of the material.

- Q: How many cubic meters of concrete mixer transport vehicle

- Between 4m and 12m cubed, it is generally chosen according to the scale of the project, the use of the road environment and a concrete casting.

- Q: Does it affect the ease of mixing too long?

- Are now using concrete products, easy to control the quality, intensity can be measured, can also add additive, etc., only their own building the in-situ mixing, transportation for a long time will affect the workability, so the project will adopt water mud and water reducing agent, etc.

- Q: What is the driving license for a concrete mixer truck?

- B2, you can do it directly. But it must be 21 years old and must be taught in permanent residence. The temporary residence is limited to the C series. The tuition fee for Beijing is 2,800 to 3100.

Send your message to us

Lifting Tank Semi Trailer with Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords