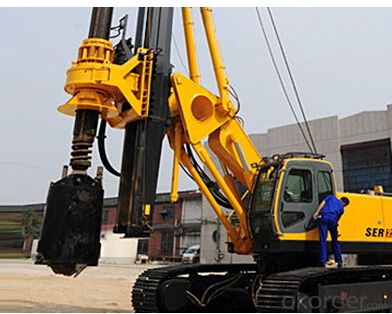

SERIE OTR560D OTR HYDRAULIC PILING RIG MACHINE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OTR560D:

①. Base: CAT 329D(HHP)

②. Max pile diameter (mm): 1800

③. Max pile depth (m): 60

④. Engine: CAT C7 ACERT 187KW

⑤. Maximum nominal torque (kNm): 200

⑥. Undercarriage with expandable (mm): 3000-4300

……More info

1. Adopts the complete OEM Caterpillar retractable-crawler dedicated chasis,Its telescopic scope between the two crawler ends extends from 3000mm(at transportation) to 4400mm(at work). Undercarriage with expandable and removable tracks by means of hydraulic cylinders, guarantee exception stabbility in any type of ground. It has considerable traction force which allows easy movement even in the most difficult job sites.

2.Takes international top CAT Diesel engine with electric injection, turbocharged and air inter-cooling system. It is high reliability, fuel economy and power reserves. Emissions meet standard EPAC-Ⅲ.

3.The winches are positioned in the lower part of the mast, in front of the cabin, so that the operator can constantly check the proper operation. Thanks to the fact that the cable moves parallely to the mast, flection is not created on the upper part of the mast and operating life of the cable is therefore much longer. Tail positioned winch is available for heavy-duty type.

4.New design parallelogram system, computer optimized design and simplified pin connection system featured with nice appearance, great driving force and good stability, especially shaped to fit crowd system, allowing working radius adjustment always maintaining the mast in vertical position. The parallelogram system is easily for convenient transform between transportation and working conditions.

5.Self-erecting mast, high level anti-shock technology and high-strenth material steel attribute to that max torque can be applied all over the mast length. Multipurpose design for cylinder crowed system. Sensor and control center realize real-time measurement of the inclination angle, auto adjustment of mast verticality and inching adjustment.

6.Crowd system by means of long stroke hydraulic cylinder or crowd winch separately, are option for your exact request.

7.Rotary head with variable displacement motors and one high spin off speed. And rotary is extremely reliable, it has been disgned in order to gurantee a very compact, efficient and powerful rotary. The transmission group of rotary is made up of a hydraulic motor and new power shift purposely studied and designed to obtain maximum perfomance. During the drilling phase, the rotary has the entire power of the diesel at its complete disposal. Adapter of rotary is essential to absorb the considerable shock connected to the high speed of the main winch.

8.Telescopic kelly bar with guide made by high quality specially for high boring strength and torque force. Available with friction or inter-locking type.

9. All the main hydraulic components(pumps, valve, motor, connector) are from well-known international brands such as Bosch-Rexroth, brevini, which ensure the stability, reliability, high-efficiency and energy-saving of the entire system

10.Electronic controlling system is an innovative system, developed by Osaint, which controls and monitors the operation of the machines. For ease of operation, the system is controlled by a touch screen located in the cab. The system function is to enable the machines to perform different functions more efficiently. A dedicated power module electronic control and CAN-Bus system ensures the main pumps and Disel engine to work at their most effective and productive stages.

- Q: What happened to the black smoke from the exhaust pipe of the rotary drilling rig?

- Lack of cylinder, cylinder, work or work to check the spark plug and ignition coil work, no change in the spark plug phenomenon, accompanied by hair shaking and force, foot relatively failure

- Q: What is the minimum diameter of a bored pile?

- The minimum diameter of the bored pile is 310 mm;

- Q: Why is the rotary drilling rig put into the steel cage before pouring?

- When pouring concrete to the reinforcement cage, if this time to improve the catheter, catheter at the bottom of the reinforcement cage distance is only about 1m distance, due to pouring concrete pipe after homing large impact force, promote the rebar cage floating;

- Q: The Montreal rotary drilling mud powder special effect is good

- My site is based in Northampton, and it feels good

- Q: What is a rotary pile?

- In China, it is an advanced pile foundation construction technology, which is widely used in recent years. It is widely used in highway, railway, bridge and large building foundation pile construction. In the early days, most of the rotary drilling rigs were imported from Germany and Italy, or Japanese second-hand rotary drilling rigs. In recent years, with the Qinghai Tibet railway, Beijing bird's nest and other projects to promote the influx of foreign brands, China's similar products are gradually developed.

- Q: What's the difference between rotary drilling rig and rotary drilling rig? What's the model?

- Drill pipe: the drill pipe of the rotary rig is 3 meters per section, and the section of the rotary drilling rig is telescopic. It is in place

- Q: How should we deal with the abnormal encountered during the construction of rotary drilling and drilling?

- When the hole is not serious, the drilling can be continued by adopting the measures of increasing the specific gravity of the mud, heightening the water head and burying the deep protecting cylinder. When the hole is serious, the backfill will be drilled again.When drilling and bending holes occur in the drilling hole, the drill bit of the rotary drill can be raised to the inclined position for repeated hole sweeping until the drilling is upright. In the event of serious bending hole, plum blossom hole, probe stone, the small stone or gravel and clay mixture backfill to deflection, to be heavy filler after re drilling deviation.When drilling, it is not strong lifting. The cause and location of the bit shall be ascertained, and large ropes shall be moved, small bit impact shall be taken, and other measures taken to make the drill loose and brought up.

- Q: In the middle of the 220 rotary drilling rig, sometimes the drill pipe slipped down 5~6 meters at work, as if the rope was broken. What's the matter?

- The first is when the card drill rod, then the clamping rod parts will appear suddenly from the above phenomenon. Generally, the drill rod is worn out, and the biggest damage to the rod is the power head and the steel wire rope.

- Q: On the cleaning of rotary drilling rig

- Rotary drilling, which meet the design requirements when the rotary drill is a few laps and idling; after several hours of the cage and the catheter after the hole and some sediment, have to clean the hole, now called the two hole cleaning. However, with the development of science and technology, the popularization and application of new technologies and materials. With the new wall protecting liquid, not only the wall is well protected, but also the hole and the sediment behind the cage seldom meet the requirements, the two cleaning procedures can be omitted, and the pile forming speed is greatly improved. For example, we use the Montreal chemical mud in construction after the Zhengzhou Xinzheng Airport, nearly 70 meters of sediment pile placed for 2 days no more than 20 cm. It brings great convenience to the construction.

- Q: 31 rotary drilling rig, 280 pairs of steel wire rope, how long?

- The main varieties of steel wire rope with manganese phosphating coating of steel wire rope, galvanized steel wire, stainless steel wire rope and coated steel wire rope, atmospheric environment, manganese phosphating coating can improve the wear resistance and corrosion resistance on the surface of the wire, inhibit the occurrence of fretting fatigue, and large increase in the fatigue life of wire rope, for reference only

Send your message to us

SERIE OTR560D OTR HYDRAULIC PILING RIG MACHINE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords