XY-44C Core Drilling Machine Of Spindle Type (1000m water well)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

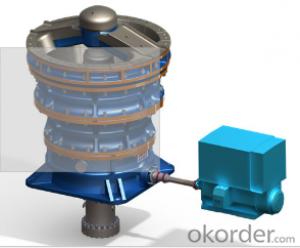

XY-44C Core Drilling MachineOf Spindle Type (1000m water well)

Application:

◊ TheXY-44C Bore Pile Drilling Machine is developed and designed newly based onXY-4,

XY-44 drilling rig of thousandmeters by Chongqing Exploration Machinery Factory.

◊ Itis suitable for large and small caliber of core drilling with diamond, tungstencarbide bits, andengineering geological technology, hydrology, water wells andlarge-caliber engineering construction hole drilling.

Features:

1. Reasonablestructure, light weight

2. Large capacity drilling, wide range of performance, goodversatility, and better quality.

3. Thewhole drilling equipment can be moved in whole, increasing drilling efficiencyand reducing labor intensity.

4. Having mast landing and folded function, it is easy to walkand transport.

5. Thedrilling rig is spindle type, mechanical transmission, hydraulic feeding, andhydraulic clampingdrilling tool. When rotary drilling it can carry out alloy-bit drilling anddiamond drilling. When impact drilling it can achieveimpact—vibration casing while drilling.

Technical Specifications:

Drilling depth( m ) | 750-1400 | |

Spindle speed (r/min) | Forward | 83;152;217;254;316;468;667;970 |

Reverse | 67;206 | |

Max. spindle torque(Nm) | 4250 | |

Spindle stroke (mm) | 600 | |

Inner diameter of spindle (mm) | Φ93 | |

Max. pull/push force(KN) | 120/90 | |

Max. hoisting force (single wire rope(KN) | 45 | |

Hoisting speed(the third layer)(m/s) | 0.70,1.29,1.84,2.68 | |

Drum capacity and wire rope dia.)(m) | 17.5mm(170kg/mm2)110 m | |

18.5mm(170kg/mm2)90 m | ||

Speed of water brake (r/min) | 700~1800 | |

Water brake balance speed of single rope / single rope balancing load | 3~8m/s/45KN | |

Rated pressure of hydraulic system(Mpa) | 8 | |

Driving stem | Driving stemΦ89×79×6000mm | |

Power unit | Electric motor | Y225S-4 37Kw 1480r/min |

Diesel engine | R4105G54 42Kw 1480r/min | |

Diesel enige | YC4108ZD 50Kw 1500r/min | |

Weight(excluding power unit) (kg) | 2200 | |

Max. detachable subassembly(kg) | 350 | |

Dimension(LXWXH) (mm) | 3038×1100×1938 | |

- Q: Rotary drilling rig piling generally dozens of meters deep, when the next reinforced concrete generally divided into several times? In other words, a few meters per hour of reinforced concrete?

- The hole depth can reach 90 meters maximum rotary drilling rig, played more than 10 meters to 30 meters for building foundation above, for the majority of the viaduct, high-speed railways are, according to the bearing capacity and the design requirements of the formation of uncertainty, all possible. Generally, the pile diameter of rotary excavation is 0.8m, 1M, 1.2m, 1.25,1.5,1.8,2 meters in the majority, 2 meters, 5 also have, or larger and smaller.

- Q: Why not use rotary drilling rig instead of manual digging pile?

- 1, can not find the right rig.2, on a drilling rig drilling too difficult.3, have luck, want to save money.

- Q: Tire type rotary drilling rig, drilling depth of 15 meters, diameter 1.2. This machine is how much money.

- I have been to the factory, and I can not say it is a lie. The equipment may be used in local geological conditions.

- Q: What's the difference between rotary drilling rig and rotary drilling rig? What's the model?

- Essential difference: 1, mud 2, move 3, drill pipe 4, drive 5, efficiency

- Q: Rotary drilling rig new steel rope appeared a strand of steel wire, what is the reason for the stock?

- Manganese phosphating belongs to wear, corrosion, phosphating, automobile transmission, steel gear is through the manganese phosphating treatment, can ensure that the car gear for more than ten years without damage. Phosphating coating of steel wire rope China patent technology production, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just add the last bonderizing process, steel wire for rope wear resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope. The fatigue test data show that the fatigue life of the phosphating coating of steel wire rope is about 3-4 times the same structure of domestic smooth steel wire rope, wire rope surface is 2-3 times of imports, (laboratory comparable conditions) with the research on the wear resistance of phosphating, and greatly enhance the possibility, is currently the most advanced technology in the world of steel wire rope field. Manganese phosphating is bonderizing, can solve the problem of wire rope wear during use, smooth wire rope being eliminated, because the phosphating coating steel wire rope in short supply, the more sought after, need to ask a few companies. For reference only

- Q: Rotary drilling rig deep hole Doumen difficulties what happened?

- It is better to take the way of impactor + water injection drilling, according to the formation conditions, match the appropriate proportion of water injection, while the impactor breaks the rock, while retaining the shaft lining with proper viscosity to prevent collapse

- Q: What is the difference between punched pile and rotary pile?

- Punching pile is the impact of heavy hammer falling, the soil or rock to disperse or break, and then floating through the mud of these debris floating, and then pumping, the pile side of the soil compaction, I think it can be ignored. Punching piles are usually rock - in. They just break the rock and squeeze it out.

- Q: What is the difference between bored pile and rotary pile?

- The construction methods of mechanical drilling pile and rotary drilling pile are different.

- Q: What is a rotary cast in place pile?

- For the good cohesive rock soil layer, dry or clear water drilling technology can be adopted, without mud wall protection. For loose and easy to collapse formations, or groundwater distribution, unstable wall, it is necessary to use static mud wall drilling technology, and put in protective wall slurry or stabilizing liquid into the hole.

- Q: The overall structure and working principle of rotary excavation?

- The auger drills, such as short auger bit, ordinary drill bit, sand drill bit, core and so on, can be drilled into different layers of clay, gravel, pebble and medium weathered mudstone.

Send your message to us

XY-44C Core Drilling Machine Of Spindle Type (1000m water well)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches