Semi-Hard and Flame retardant PVC compound for fiber cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

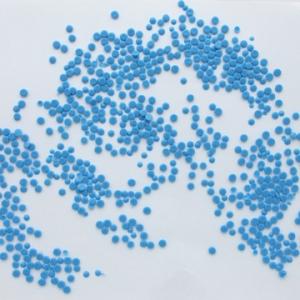

Semi-Hard and Flameretardant PVC compound for fiber cable

I. Type andapplication

Type | Product | Application and Cable Specification |

1601N | 70℃ semi-hard flame retardant PVC jacket compound for fiber cable | Applied to fiber cable as inner jacket, which is semi-hard and flame retardant. |

1823N | 70℃ semi-hard flame retardant PVC jacket compound for fiber cable | Applied to fiber cable as outer jacket, which is semi-hard and flame retardant. |

1601N-1 | 105℃ semi-hard flame retardant PVC jacket compound for fiber cable | Applied to fiber cable as inner jacket, which is semi-hard and flame retardant. |

1823N-2 | 90℃ semi-hard flame retardant PVC jacket compound for fiber cable | Applied to fiber cable as outer jacket, which is semi-hard and flame retardant. |

II. Productdescription

Semi-hard and flame retardant PVC jacketcompound for fiber cable, based on PVC resin, is made into granula by mixing,plastification and granulation with adding plasticizer, stabilizing agent,modifying agent, pigment and etc. The products meet various specialrequirements, such as different hardness, UV stable, environment friend (RoHs,REACH, PAHs, chlorinated alkanes free, phthalate free, and etc.), sub-shine and fog surface, low temperatureresistant, PS/ABS transfer proof, rodent-repellent, termite-repellent, andtransparent, and etc.

III. Processing

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20.

The following temperature(℃) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 160 | 170 | 175 | 180 | 175 |

IV. Storageand transport

Packaging:25kg/bag, PEmembrane inside bag and Kraft outside bag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, andventilated conditions.

V. Properties

Table

Item | Unit | Standard Value | |||

1601N | 1823N | 1601N-1 | 1823N-2 | ||

Tensile Strength | ≥MPa | 15.0 | 15.0 | 15.0 | 15.0 |

Elongation at Break | ≥ % | 150 | 180 | 150 | 180 |

Volume Resistivity, at 20℃ | ≥Ω.m | 1.0×109 | 1.0×109 | 1.0×109 | 1.0×109 |

Dielectric Strength | ≥MV/m | 18 | 18 | 18 | 18 |

Hot Deformation | ≤ % | 40 | 40 | 40 | 40 |

Thermal Stability Time at 200℃ | ≥ min | 80 | 80 | 80 | 80 |

Oxygen Index | ≥ % | 30 | 28 | 30 | 28 |

Hardness | A | 95±2 | 85±2 | 98±2 | 92±2 |

Thermal Aging |

|

|

|

|

|

Aging Temperature | ℃ | 100±2 | 100±2 | 135±2 | 100±2 |

Aging Time | h | 168 | 168 | 168 | 240 |

Tensile Strength after aging | ≥MPa | 15.0 | 15.0 | 15.0 | 15.0 |

Variation on Tensile Strength | ≤ % | ±20 | ±20 | ±20 | ±20 |

Elongation at Break after aging | ≥ % | 150 | 180 | 150 | 180 |

Variation on Elongation at Break | ≤ % | ±20 | ±20 | ±20 | ±20 |

Loss of Mass after aging | ≤ g/m2 | - | - | - | - |

- Q: Can olive nets be used to protect against hail damage?

- Yes, olive nets can be used to protect against hail damage. Olive nets are commonly used in agriculture to cover crops and provide protection against various weather elements, including hail. The nets create a barrier that helps absorb the impact of hailstones, reducing the potential damage to the plants.

- Q: How do olive nets affect the growth of olive tree flowers?

- Olive nets help protect the growth of olive tree flowers by preventing damage from pests, birds, and strong winds. These nets create a barrier that shields the flowers from external factors, allowing them to develop and bloom undisturbed. Additionally, the nets provide shade, regulating temperature and reducing water evaporation, which can enhance flower growth. Overall, olive nets positively impact the growth of olive tree flowers by providing a conducive environment for their development.

- Q: Can olive nets be used to reduce pesticide applications?

- Yes, olive nets can be used to reduce pesticide applications.

- Q: White plastic for a long time. Why does it turn yellow?

- So, want to make white plastic use more longer, try to avoid bright light, if and food related, try to use transparent colorless plastic. If you want to cure this phenomenon, you can add a certain smooth stabilizer.

- Q: Does high strength polyurethane belong to plastics?

- But now there are some materials that are both plastic and rubber, and it's difficult to identify which category, such as TPO, TPV, elastomer nylon (material for car tires)

- Q: Can olive nets be used to improve fruit coloration?

- Yes, olive nets can be used to improve fruit coloration. Olive nets provide shade to the fruits, reducing sunburn and heat stress, which can lead to better color development in the fruit. Additionally, the nets protect the fruits from pests and birds, allowing them to fully ripen and develop their natural color.

- Q: How does an olive net affect the overall water usage in the olive grove?

- An olive net helps reduce overall water usage in an olive grove by preventing evaporation and retaining moisture in the soil.

- Q: Why don't you put the plastic bags in the fridge?

- Don't put the plastic bags in the refrigerator, or the consequences will be serious.

- Q: Can olive nets be used for olive trees grown in greenhouses?

- No, olive nets are typically not used for olive trees grown in greenhouses as they are primarily used for outdoor cultivation to protect the fruits from birds and other pests. In a greenhouse setting, other methods such as manual pollination and controlled pest management are employed.

- Q: Do olive nets affect the quality or taste of the olives?

- Yes, olive nets can affect the quality and taste of the olives. The nets protect the olives from pests and falling on the ground, minimizing damage. However, if the olives remain on the tree for an extended period, they may become overripe and lose some of their flavor. Additionally, the nets can create a microclimate that affects the maturation process, potentially altering the taste of the olives. Therefore, while olive nets offer protection, their use should be carefully managed to ensure optimal quality and taste.

Send your message to us

Semi-Hard and Flame retardant PVC compound for fiber cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords