Semi Gloss PVC Electrical Insulation Tape with Good Adhesion

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Tape

PVC tapes are made of soft pvc film coated with rubber pressure-sentitive adhesive.

Application of PVC Tape

PVC tapes are widely used in auto harness, wrapping of wire, and insulation protection. It is the main insulation material of automobilehousehold electrical apparatus.

Advantage of PVC Tape

Corrosion protection for metal piping systems above and below ground.

Corrosion protection for fittings and joints on mill coated pipe.

Corrosion protection of electrical conduit & fittings.

Resists corrosive action by salt water, soil acids, alkalies and salts.

Prevents dielectric corrosion between buried steel pipe and soil minerals.

Pictures of PVC Tape

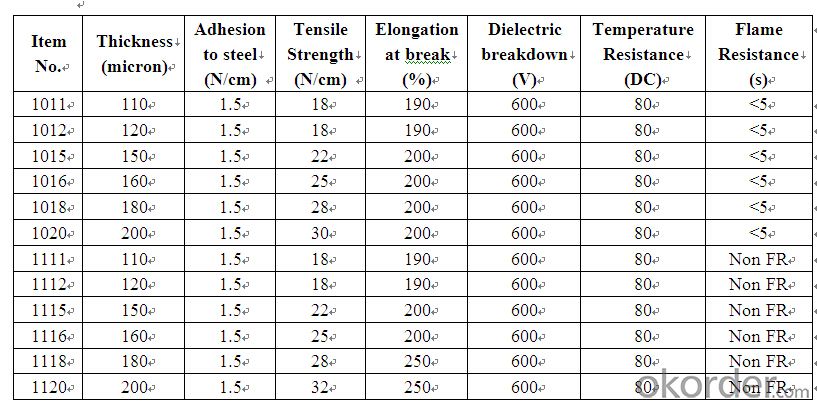

Specification of PVC Tape

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

- Q: Are there specific brands of packaging tape that are recommended?

- Certainly, there exist specific brands of packaging tape that are frequently suggested due to their quality and dependability. Noteworthy and highly respected brands encompass Scotch, Duck, 3M, Gorilla, and Uline. These particular brands are renowned for crafting packaging tapes that possess robust adhesive properties, exceptional durability, and the capability to effectively seal boxes and packages. Moreover, these brands frequently provide an array of options, including diverse widths, lengths, and types of tape (e.g., clear, colored, or reinforced), catering to various packaging needs. Nevertheless, it is always advisable to take into account the specific demands of your packaging task and peruse customer reviews prior to settling on a brand of packaging tape.

- Q: Does packaging tape come in different materials for specific applications?

- Yes, packaging tape does come in different materials for specific applications. These materials include polypropylene, PVC, paper, and filament tape. Each material has unique properties that make it suitable for various purposes such as sealing lightweight packages, securing heavy boxes, or providing extra strength and tear resistance.

- Q: Can packaging tape be used for sealing perishable food items?

- No, packaging tape should not be used for sealing perishable food items. It is not designed to provide airtight or food-safe seals, and it may contaminate the food with adhesives or chemicals. It is recommended to use proper food-grade packaging materials such as plastic wrap or food storage bags for sealing perishable food items.

- Q: How does packaging tape adhere to surfaces?

- Packaging tape adheres to surfaces through the use of adhesive materials. The adhesive on packaging tape is typically made from a synthetic rubber or acrylic-based material. These materials are designed to have a strong bonding ability to various surfaces such as cardboard, plastic, or metal. The adhesive on packaging tape works by creating a bond between the tape and the surface it is applied to. When pressure is applied to the tape, the adhesive material spreads and makes contact with the surface. This contact allows the adhesive to interact with the surface's molecules, creating a bond through intermolecular forces. The most common type of adhesive used on packaging tape is pressure-sensitive adhesive (PSA). PSA is designed to stick to surfaces with the application of light pressure. When pressure is applied, the adhesive material flows and conforms to the surface, creating a strong bond. The adhesive on packaging tape is also designed to be resistant to various environmental factors such as temperature, humidity, and moisture. This ensures that the tape remains securely adhered to the surface even under challenging conditions. In summary, packaging tape adheres to surfaces through the use of adhesive materials, typically synthetic rubber or acrylic-based. These adhesives create a bond between the tape and the surface through intermolecular forces, allowing the tape to stick securely.

- Q: Is packaging tape resistant to chemicals?

- Yes, packaging tape is typically resistant to chemicals. It is designed to withstand various substances and maintain its adhesive properties, making it an effective choice for securing packages and protecting their contents.

- Q: Can packaging tape be used for sealing plastic garment bags?

- Yes, packaging tape can be used for sealing plastic garment bags. It provides a strong and reliable adhesive that helps keep the bags securely sealed.

- Q: Can packaging tape be used for sealing poly mailers?

- Yes, packaging tape can be used for sealing poly mailers. It provides a secure and durable seal that helps protect the contents of the poly mailers during transit.

- Q: What are the considerations for using packaging tape on temperature-sensitive items?

- When using packaging tape on temperature-sensitive items, there are several considerations to keep in mind. Firstly, it is important to choose the right type of packaging tape. There are temperature-resistant tapes available specifically designed to withstand extreme temperatures. These tapes are usually made with materials that can withstand high or low temperatures without losing their adhesive properties or deforming. It is crucial to select a tape that is suitable for the temperature range the item will be exposed to during storage, transportation, or any other handling processes. Secondly, it is important to properly store the packaging tape. Extreme temperatures can affect the adhesive properties of tape, causing it to become less effective. It is advisable to store the tape in a climate-controlled environment, away from direct sunlight or areas with excessive heat or cold. This will help maintain the adhesive strength and overall quality of the tape. Additionally, when applying packaging tape to temperature-sensitive items, it is important to ensure that the surface is clean and dry. Any moisture or dust particles on the surface can compromise the adhesion of the tape and lead to inadequate sealing. Properly preparing the surface will help ensure a secure and reliable bond between the tape and the item. Furthermore, it is essential to consider the duration of exposure to extreme temperatures. If the item will be exposed to high or low temperatures for an extended period, it may be necessary to use additional protective measures such as insulation or specialized packaging materials to provide extra insulation. Lastly, it is important to test the tape's performance before using it on temperature-sensitive items. Conducting a small-scale trial or using a sample item can help determine if the tape is suitable for the specific temperature conditions. This will help identify any potential issues or limitations before using the tape on valuable or delicate items. In conclusion, when using packaging tape on temperature-sensitive items, it is crucial to select the appropriate tape, store it properly, prepare the surface adequately, consider the duration of temperature exposure, and test the tape's performance. By considering these factors, one can ensure the safe and secure packaging of temperature-sensitive items.

- Q: What are the different types of packaging tape available?

- There are several different types of packaging tape available, each designed for specific purposes and applications. Here are some common types: 1. Clear packaging tape: This is the most commonly used type of packaging tape. It is transparent and provides a strong adhesive bond for sealing boxes and packages. Clear tape is versatile and suitable for a wide range of applications. 2. Brown packaging tape: Also known as "brown tape" or "packing tape," this type of tape is made from brown or tan-colored material, usually reinforced with fiberglass. It offers excellent strength and durability for securing heavy or bulky packages. 3. Masking tape: While not specifically designed for packaging, masking tape can be used for light-duty sealing or labeling purposes. It is easily removable and leaves no residue, making it ideal for temporary applications. 4. Duct tape: Often recognized for its strength and versatility, duct tape is not primarily designed for packaging but can be used in certain situations. It has a strong adhesive bond and is known for its ability to stick to a wide range of surfaces, including uneven or rough ones. 5. Filament tape: This type of tape is reinforced with fiberglass filaments, providing exceptional strength and resistance. Filament tape is commonly used for bundling or reinforcing heavy or irregularly shaped items. 6. Double-sided tape: Unlike other types of packaging tape, double-sided tape has adhesive on both sides and is used for various applications, such as bonding two surfaces together or mounting objects. 7. Kraft paper tape: Made from a renewable resource, kraft paper tape is an eco-friendly alternative to plastic tapes. It is water-activated and requires moistening before application. Kraft paper tape provides a strong seal and is often used for sealing cartons or packages containing valuable or fragile items. 8. Colored packaging tape: This type of tape is available in various colors and is commonly used for color-coding packages, labeling, or adding aesthetic appeal to packages. These are just some of the different types of packaging tape available in the market. Each type has its own unique characteristics and is suitable for specific packaging needs. When choosing the appropriate tape, it is important to consider factors such as the weight and nature of the package, the environment it will be exposed to, and any specific requirements or regulations that may apply.

- Q: Can packaging tape be used for sealing plastic storage bags?

- Yes, packaging tape can be used for sealing plastic storage bags. It provides a strong adhesive bond that helps keep the bags tightly sealed, preventing any air or moisture from entering. This can be particularly useful when storing food, clothes, or other items that need to be protected from dirt, dust, or potential damage. However, it is important to note that using packaging tape may not provide as secure of a seal as using specialized bag sealers or sealing clips. These alternatives are designed specifically for plastic bags and may offer a more reliable seal.

Send your message to us

Semi Gloss PVC Electrical Insulation Tape with Good Adhesion

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches