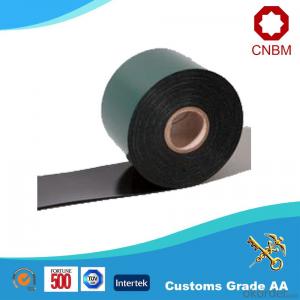

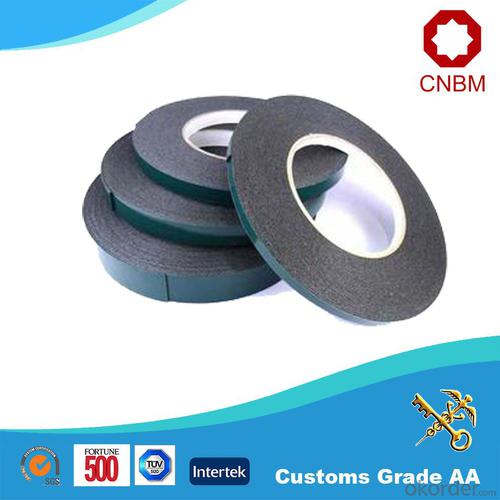

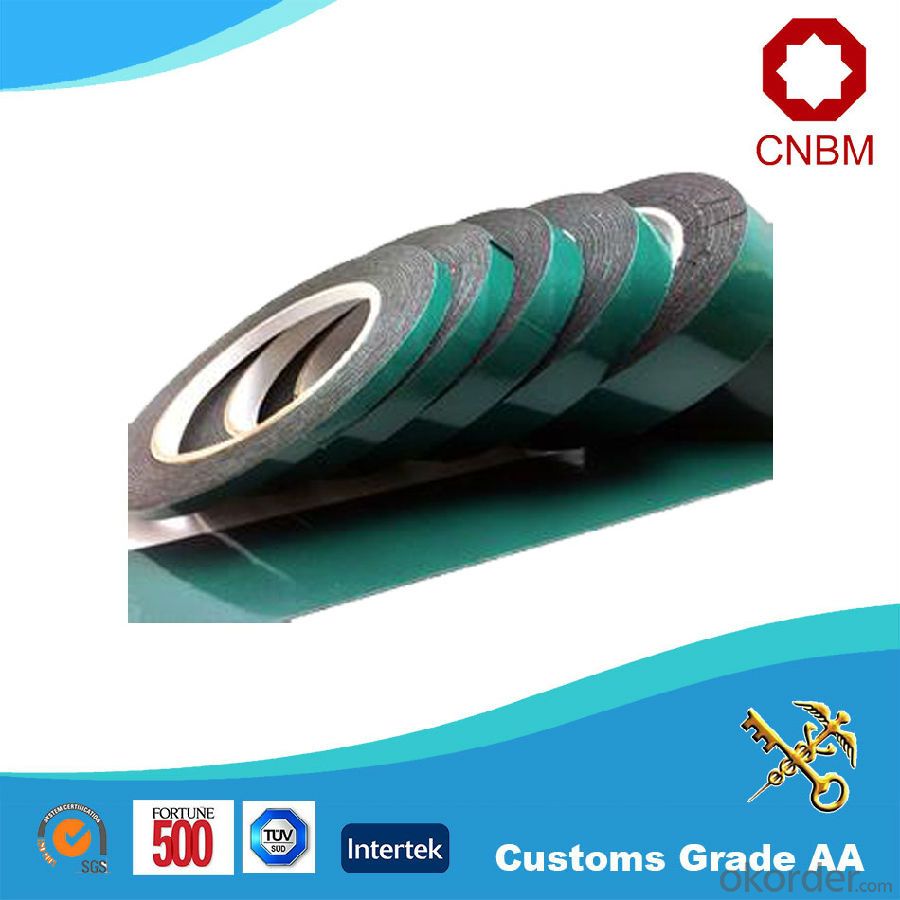

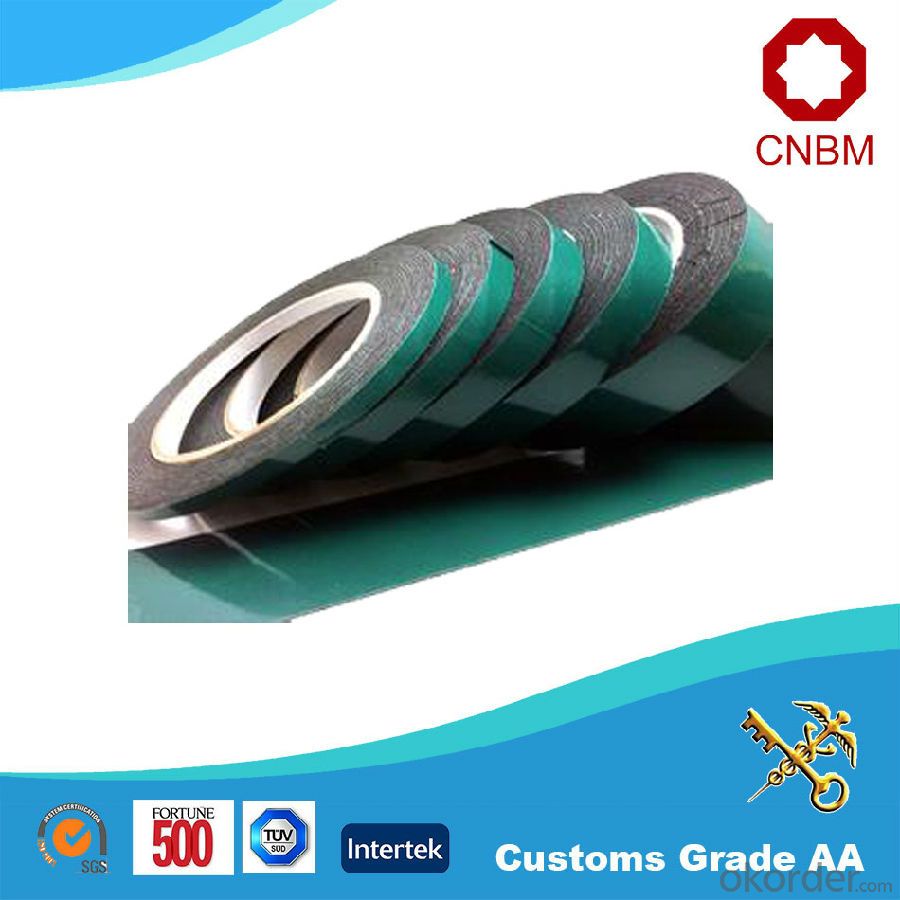

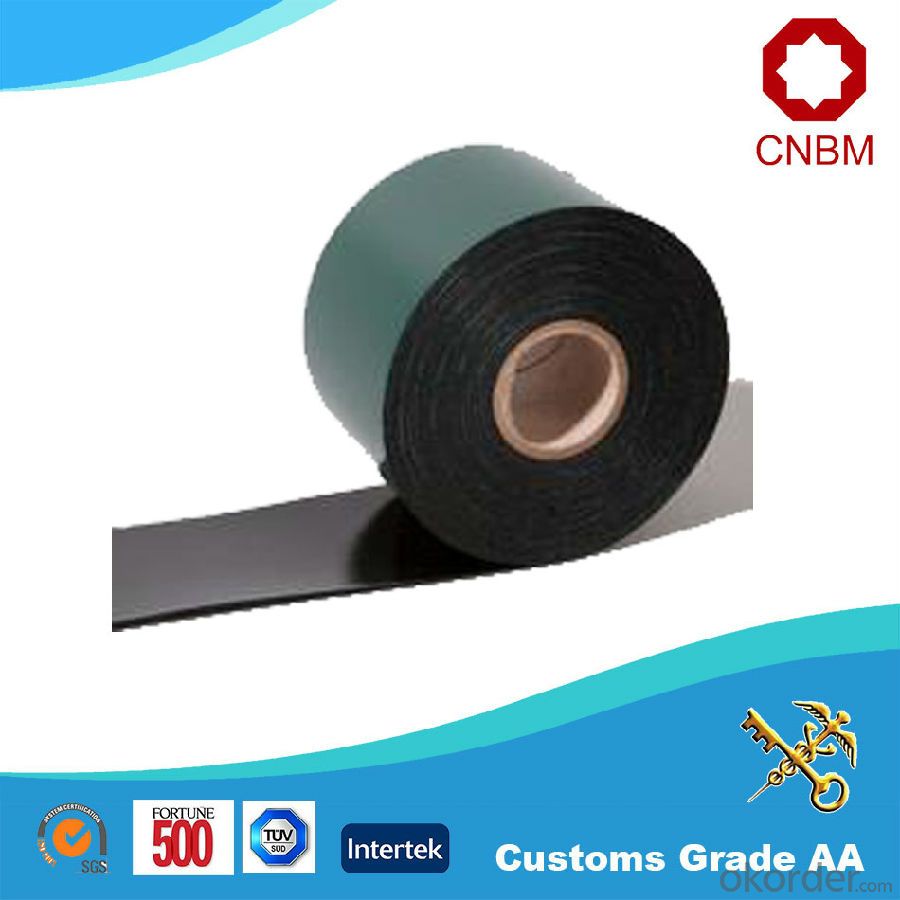

Security Packaging Tape - Double Sided Foam Tape PE Foam Blue Release Black Foam for Auto, Electronic, and Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m

- Supply Capability:

- 2000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Double Sided Foam Tape PE Foam Blue Release Black Foam for Auto Electronic and Construction

Product Description

Double Sided Foam Tape is of PE foam or EVA foam as the carrier, coating with hot melt adhesive, solvent based acrylic. Double Sided Foam Tape is widely used in the auto, electronic and construction industries.

FEATURES:

l Excellent in adhesion and flame retardant

l Resistance to cold, heat and aging.

l High Temperature stability

l High mechanical strength and good impact resistance

l Ideal for use in dispensers

l Printable

Data Sheet

| Item NO. | DSP08YM |

| Carrier | PE Foam |

| Adhesive | Hot melt/Solvent |

| Thickness (mm) | 0.8 |

| Density (kg/m3) | 120 |

| Peel Adhesion (N/25mm) | 12 |

| Holding Power (H) | 100 |

| Packing | Carton |

| Delivery | With 10-20 days after deposit |

| Payment | TT & LC |

Authorized Certificate

Production Line

Exhibition Domestic and Oversea

Company

China National Building Materials Group is a state-owned company. As World Top 500 companies, we have clients from over 160 countries and wholly-owned overseas subsidiaries and branches in 10 countries. We supply adhesive tape for over twenty years.

We supply various adhesive tapes: cloth tape, double sided tape, PVC tape, aluminum foil tape, Opp tape, masking tape and so on. All our products have been SGS and ISO9001 certified and exported with Grade AA approval. The quality and performance all meet the advanced international levels.

We not only own professional manufacturers in China, but also work with many famous brands as agents. We can provide OEM Design & Brand as you required.

FAQ

1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

2. What can we do for you?

Professional consultation on your local market

Custom-made advices for your need

Free samples

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Satisfactory sales service

3. Delivery time

7-25 days after receiving the deposit

4. Packing and Shipping

36 Rolls per Caron.

5. What is other specifications of double sided tape?

Double Sided Tissue Tape: widely used for bonding, fixing for leather, foam, sponge, garment, shoe, luggage, plastic, paper splicing and stationery.

Double Sided PET Tape is wildly used for carpet fixing, flying splice operations on film, bag cover sealing, bounding, foam lamination and others.

Double Sided Cloth Tape is ideal for carpet fixing, bag cover sealing, bundling, flying spice operations and other industrial.

- Q: What are the considerations for using packaging tape on delicate surfaces?

- When using packaging tape on delicate surfaces, it is important to consider a few factors. Firstly, opt for a tape specifically designed for delicate surfaces, such as low-tack or painter's tape. This type of tape is less likely to cause damage or leave residue. Secondly, ensure that the surface is clean and free of any dirt or debris before applying the tape. This will help prevent any potential scratching or damage. Additionally, apply the tape gently and avoid excessive pressure or stretching, as this can cause the tape to adhere too strongly and potentially harm the delicate surface. Finally, when removing the tape, do so slowly and at a low angle to minimize the risk of tearing or leaving adhesive residue behind. By considering these factors, you can effectively use packaging tape on delicate surfaces while minimizing the risk of damage.

- Q: Can packaging tape be used for sealing plastic clamshell packaging?

- Yes, packaging tape can be used for sealing plastic clamshell packaging. Packaging tape is designed to securely seal various types of packaging materials, including plastic clamshell packaging. It provides a strong adhesive bond that holds the clamshell packaging together and prevents it from opening during shipping or handling. Additionally, packaging tape is durable and tear-resistant, ensuring that the clamshell packaging remains sealed and protected throughout the entire distribution process.

- Q: What are the benefits of using pre-printed packaging tape with warning messages?

- Using pre-printed packaging tape with warning messages has several benefits. Firstly, it helps to ensure the safety of the package contents and the individuals handling them. The warning messages act as a visual reminder of any potential hazards or special handling instructions, reducing the risk of accidents or mishandling. Secondly, it saves time and effort by eliminating the need for separate warning labels or writing instructions on the packaging. The pre-printed tape provides a clear and professional warning message that can be easily recognized by anyone involved in the packaging process. Lastly, it enhances the overall professionalism and branding of the company. The customized warning messages on the tape can include the company's logo, contact information, or any other branding elements, making the package stand out and leaving a positive impression on the recipient.

- Q: What are the considerations for using packaging tape on painted surfaces?

- When considering using packaging tape on painted surfaces, there are several important considerations to keep in mind. Firstly, it is crucial to assess the type and condition of the paint on the surface. If the paint is old, flaking, or in poor condition, using packaging tape may cause further damage such as peeling or chipping off the paint. In such cases, it is advisable to avoid using tape directly on the painted surface. Another important consideration is the adhesive strength of the packaging tape. Some tapes have strong adhesives that may stick firmly to the painted surface, making it difficult to remove without damaging the paint. It is recommended to test a small, inconspicuous area with the tape to ensure it can be safely removed without leaving residue or causing any harm. Furthermore, it is crucial to consider the duration for which the tape will be applied. If the tape is intended to be left on the painted surface for an extended period, there is a higher risk of it causing damage. Over time, the adhesive may bond more strongly with the paint, making it harder to remove without causing any harm. Additionally, the surface texture plays a role in determining the suitability of using packaging tape. Rough or uneven surfaces may not allow the tape to adhere properly, leading to lifting or peeling, which can damage the paint. Lastly, it is essential to consider the purpose of using packaging tape on the painted surface. If the objective is to protect the paint from scratches or damage during transportation or storage, alternative methods such as using protective sheets or bubble wrap may be more suitable and less likely to harm the paint. In conclusion, when considering using packaging tape on painted surfaces, one must assess the type and condition of the paint, adhesive strength, duration of application, surface texture, and the purpose of using the tape. By taking these considerations into account, one can ensure that the tape is used safely without causing any damage to the painted surface.

- Q: Does packaging tape come in different finishes or textures for aesthetic purposes?

- Different finishes and textures are available for packaging tape to cater to aesthetic preferences. While the main purpose of packaging tape is to securely seal boxes and packages, manufacturers understand the significance of aesthetics in packaging. Consequently, they have created packaging tapes with various finishes and textures to accommodate diverse preferences. Certain packaging tapes have a glossy finish, which gives the package a polished and professional appearance. These tapes typically have a smooth and shiny surface that reflects light, resulting in a visually appealing package. Glossy packaging tapes are commonly used in industries that require a high-end presentation, such as luxury goods or high-quality products. On the other hand, there are also packaging tapes with matte or satin finishes. These tapes provide a more subtle and refined look to the package, exuding sophistication. Matte or satin tapes are often preferred in industries that value a more understated aesthetic, such as cosmetics or boutique products. In addition to finishes, packaging tape can also have different textures. For instance, some tapes feature a textured or patterned surface, adding a tactile element to the packaging. These tapes may have embossed patterns like dots, stripes, or even company logos, enhancing the overall visual appeal and distinctiveness of the package. In conclusion, packaging tape is available in various finishes and textures to satisfy aesthetic needs. Whether it is a glossy, matte, satin, or textured surface, these options allow businesses to choose packaging tape that aligns with their branding and desired presentation. By utilizing different finishes and textures, packaging tape not only fulfills its primary function but also contributes to a more visually appealing and personalized packaging experience.

- Q: What are the benefits of using silent packaging tape?

- There are several benefits of using silent packaging tape. Firstly, silent packaging tape provides a noise-free packaging experience. This is particularly beneficial in environments where silence is necessary, such as in offices, libraries, or other quiet spaces. By eliminating the loud noise typically associated with traditional packaging tape, silent tape helps maintain a peaceful and calm atmosphere. Secondly, silent packaging tape is preferred by employees who handle packaging tasks on a regular basis. The absence of noise during the taping process reduces the risk of noise-induced stress or fatigue, contributing to a more comfortable working environment. This can lead to increased productivity and employee satisfaction. Moreover, silent tape is a great option for businesses that prioritize customer satisfaction. When packaging items for shipment, especially fragile or delicate items, using silent tape ensures a professional and polished appearance. The absence of loud noise during the packaging process also avoids potential disturbance or annoyance to customers, both during the packaging phase and when they receive their packages. Additionally, silent packaging tape is often designed with high-quality adhesive properties. This means that it provides a secure and durable seal, keeping packages intact during transit. This reduces the likelihood of damaged goods and the associated costs of re-shipping or replacing items. Lastly, silent tape is often made from eco-friendly materials. This is advantageous for businesses aiming to reduce their environmental impact. By choosing silent packaging tape made from recyclable or biodegradable materials, companies can align their packaging practices with their sustainability goals. In conclusion, the benefits of using silent packaging tape include noise reduction, improved employee satisfaction and productivity, enhanced customer experience, secure sealing, and eco-friendliness. By opting for silent tape, businesses can create a more efficient, pleasant, and environmentally conscious packaging process.

- Q: Is packaging tape resistant to chemicals or solvents?

- Yes, packaging tape is generally resistant to chemicals or solvents. Most packaging tapes are made from materials such as polypropylene or polyvinyl chloride (PVC) which have good chemical resistance properties. These materials are designed to withstand exposure to a wide range of chemicals and solvents commonly encountered in industrial or commercial environments. However, it is important to note that the specific resistance of packaging tape can vary depending on the brand, type, and quality of the tape. Therefore, it is always recommended to check the product specifications or consult the manufacturer for detailed information on the chemical resistance of a specific tape.

- Q: Can packaging tape be used for securing shipments during transit?

- Absolutely, packaging tape is perfect for securing shipments while they are being transported. It is specifically engineered to create a sturdy and dependable seal for packages, guaranteeing their safety and preservation throughout transportation. It is commonly employed to seal cardboard boxes, fasten bubble wrap or other protective materials around items, and reinforce package closures. Packaging tape is long-lasting, user-friendly, and creates a strong adhesive connection, making it the ideal option for securing shipments in transit.

- Q: Can packaging tape be used for sealing packages with sharp edges or corners?

- Yes, packaging tape can be used for sealing packages with sharp edges or corners. Packaging tapes are designed to be strong and durable, allowing them to securely seal boxes and packages of various shapes and sizes. They are commonly used in shipping and packaging industries to ensure that the contents of a package remain intact during transit. The adhesive on the tape is typically strong enough to adhere to sharp edges and corners, providing a reliable seal. However, it is important to ensure that the tape is applied properly and securely to prevent any potential damage or tampering during shipping.

- Q: Which kind of adhesive tape is of good quality?

- Is the material new?. Does glue keep its color for a long time?. The thickness of the tape is not thicker, the better.

Send your message to us

Security Packaging Tape - Double Sided Foam Tape PE Foam Blue Release Black Foam for Auto, Electronic, and Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m

- Supply Capability:

- 2000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords