Seamless Steel Pipe with Best Price and High Quality/Hot Sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DETAILS

1.Structure of Seamless Steel Pipe Description:

A large amount of Seamless Steel Pipes is offered to the clients at cost effective rates. These pipes are extremely durable, resistant to corrosion and have high tensile strength. Our pipes are used in nuclear plants, power plants, refineries and construction industry across the country. Furthermore, we are capable of providing these seamless pipes to the clients in bulk quantity.

2.Main Features of the Steel Pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

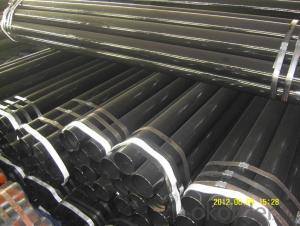

3.Seamless Steel Pipe Pictures:

4.FAQ of Seamless steel pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust.

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: How are steel pipes tested for quality?

- Steel pipes are tested for quality through various methods such as visual inspections, dimensional measurements, and various mechanical and chemical tests. These tests include assessing the pipe's surface finish, checking for any defects or cracks, measuring its dimensions, conducting tensile and impact tests, and analyzing its composition. Additionally, non-destructive testing techniques like ultrasonic testing, radiography, and magnetic particle inspection are employed to ensure the pipes meet the required quality standards.

- Q: What are the different testing methods for steel pipes?

- There are several testing methods for steel pipes, including visual inspection, ultrasonic testing, magnetic particle testing, dye penetrant testing, radiographic testing, and hydrostatic testing.

- Q: Can steel pipes be used for underground gas distribution?

- Indeed, underground gas distribution can make use of steel pipes. Within the gas industry, steel pipes are widely employed due to their exceptional strength, durability, and resistance to corrosion. These pipes possess the capacity to endure the pressure and stress inherent in gas distribution systems. Moreover, steel pipes have demonstrated their reliability and safety as a means of transporting natural gas below ground. Nevertheless, it is crucial to ensure that these steel pipes are adequately coated and shielded against corrosion in order to preserve their integrity and prolong their lifespan. Consistent inspections and maintenance procedures are also imperative to detect and rectify any potential problems that may arise.

- Q: Can steel pipes be painted or coated?

- Yes, steel pipes can be painted or coated. Painting or coating steel pipes helps to protect them from corrosion, rust, and other environmental factors. It also enhances their aesthetic appearance and can be used to indicate the type of pipe or its function.

- Q: How do you protect steel pipes from fire?

- To protect steel pipes from fire, there are several measures that can be taken. One commonly used method is to apply fire-resistant coatings or paints to the surface of the pipes. These coatings or paints are designed to withstand high temperatures and provide a barrier that prevents the heat from reaching the steel. Another effective way to protect steel pipes from fire is to wrap them with fire-resistant insulation materials. These materials act as a buffer, reducing the heat transfer and slowing down the spread of fire. Insulation materials such as mineral wool or ceramic fiber blankets are commonly used for this purpose. In addition, it is important to ensure that the steel pipes are properly installed and supported. This includes maintaining proper clearance from other flammable materials and avoiding overcrowding or obstructions that could impede the flow of air around the pipes. Adequate spacing between pipes is also crucial to prevent the transfer of heat from one pipe to another. Furthermore, it is recommended to incorporate firestop systems when steel pipes pass through fire-rated walls or floors. Firestop systems consist of fire-resistant materials and seals that prevent the spread of fire and smoke through openings or penetrations in fire-rated barriers. Regular maintenance and inspections are essential to ensure the ongoing effectiveness of the fire protection measures. Any damage or deterioration of the coatings, insulation, or firestop systems should be promptly repaired or replaced to maintain the fire resistance of the steel pipes. Overall, a combination of fire-resistant coatings, insulation, proper installation, and maintenance practices are crucial in protecting steel pipes from fire hazards. These measures help to minimize the risk of fire-related damage and ensure the safety of both the pipes and the surrounding environment.

- Q: How do steel pipes differ from other types of pipes?

- Steel pipes differ from other types of pipes in several ways. Firstly, steel pipes are incredibly durable and strong, making them suitable for carrying high-pressure fluids and gases. They have a high resistance to corrosion and can withstand extreme temperatures, making them ideal for various industrial applications. Additionally, steel pipes have a smooth interior surface, which reduces friction and allows for efficient flow of liquids or gases. They are also highly versatile, as they can be easily welded, threaded, or bent to fit specific project requirements. Overall, steel pipes are known for their strength, durability, and versatility, making them a preferred choice in many industries.

- Q: What are the different methods of joining steel pipes without welding?

- There are several methods of joining steel pipes without welding, including: 1. Mechanical Couplings: These couplings consist of two separate pieces that are attached to the ends of the pipes and then tightened together. They provide a secure and leak-proof connection without the need for welding. 2. Threaded Connections: In this method, the ends of the steel pipes are threaded to create a male and female connection. The pipes are then screwed together using pipe threads, providing a strong and reliable joint. 3. Flanged Connections: Flanges are used to connect steel pipes by bolting them together. The flanges have a flat surface with holes that align with corresponding holes in the opposite flange. Bolts are then inserted and tightened to create a tight seal. 4. Grooved Connections: This method involves grooving the ends of the steel pipes and then using grooved couplings to join them. The couplings have teeth that interlock with the grooves, creating a secure and rigid connection. 5. Compression Fittings: Compression fittings are used to join steel pipes by compressing a metal or plastic ring onto the pipe's outer surface. This creates a tight seal and a reliable connection, without the need for welding. 6. Adhesive Bonding: Special adhesives designed for metal bonding can be used to join steel pipes. The adhesive is applied to the surfaces of the pipes, which are then pressed together and left to cure, creating a strong and durable bond. 7. Clamping: Clamps can be used to hold steel pipes together, creating a temporary connection. This method is commonly used for testing purposes or in situations where the pipes need to be easily disassembled. Each of these methods has its own advantages and limitations, and the choice depends on factors such as the specific application, pipe material, and the required strength of the joint.

- Q: Where is the difference between seamless steel pipe and welded pipe?

- Seamless steel tube is formed during rolling. Welded steel pipes need to be welded after coiling, and spiral welding and direct welding are generally used. Seamless performance is better, of course, the price is higher.

- Q: What is the cost of steel pipes compared to other piping materials?

- The cost of steel pipes compared to other piping materials can vary depending on factors such as the size, grade, and specifications of the pipes, as well as market conditions and location. In general, steel pipes tend to be more expensive than some alternative piping materials such as PVC (polyvinyl chloride) or HDPE (high-density polyethylene). However, when compared to other materials like copper or stainless steel, steel pipes can often be more cost-effective. Steel pipes are known for their durability, strength, and resistance to high pressures and temperatures, making them suitable for various applications such as oil and gas pipelines, plumbing systems, and structural supports. Their longevity and reliability can offset the initial higher cost, as they often require less maintenance and have a longer lifespan than other materials. Additionally, steel pipes are readily available in different sizes and grades, making them versatile and adaptable to different project requirements. This availability and versatility can contribute to their cost-effectiveness, as they can be easily sourced and customized to specific needs. It's important to note that prices for steel pipes can fluctuate due to market conditions and factors such as raw material costs, transportation expenses, and labor charges. Therefore, it is advisable to consult with suppliers or industry experts to get accurate pricing information for steel pipes based on specific project specifications and market conditions.

- Q: How does the price of steel pipes fluctuate?

- The price of steel pipes can fluctuate due to several factors, including changes in raw material costs, supply and demand dynamics, global economic conditions, and trade policies. For example, a rise in the cost of iron ore or other metals used in steel production can lead to an increase in the price of steel pipes. Similarly, a decrease in demand for construction or infrastructure projects can lower the demand for steel pipes, leading to a decrease in prices. Additionally, changes in trade policies, such as tariffs or restrictions on imports or exports, can also impact steel pipe prices. Overall, the price of steel pipes is influenced by various market forces and external factors, causing it to fluctuate over time.

Send your message to us

Seamless Steel Pipe with Best Price and High Quality/Hot Sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords