Carbon Seamless Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Carbon Seamless Pipe :

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. Since the manufacturing process does not include any welding, seamless pipes are regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of the Carbon Seamless Pipe :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Carbon Seamless Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one. Please kindly trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

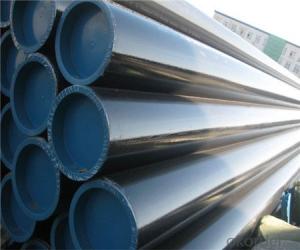

6、Seamless Pipe Images:

- Q: What are the different types of steel coatings used for pipes?

- Some of the different types of steel coatings used for pipes include epoxy coatings, polyethylene coatings, fusion bonded epoxy (FBE) coatings, and zinc coatings.

- Q: Can steel pipes be used for airport construction?

- Yes, steel pipes can be used for airport construction. Steel pipes are commonly used in various applications in the construction industry, including airports. They are often used for underground utilities such as water and sewage lines, as well as for structural purposes such as supporting the airport terminal building. Steel pipes offer several advantages for airport construction. Firstly, they have high strength and durability, making them suitable for handling heavy loads and withstanding adverse weather conditions. This is important for ensuring the safety and stability of airport structures. Secondly, steel pipes are versatile and can be easily customized to fit specific project requirements. They come in various sizes and thicknesses, allowing for flexibility in design and construction. Additionally, steel pipes can be welded or joined together to create longer sections, which simplifies installation and reduces construction time. Moreover, steel pipes are resistant to corrosion, which is crucial in airports where there is constant exposure to moisture, salt, and other environmental factors. Their resistance to corrosion ensures the longevity and reliability of the infrastructure. Lastly, steel pipes are cost-effective compared to other materials such as concrete or PVC. They have a relatively low maintenance requirement and a long lifespan, reducing the need for frequent repairs or replacements, thus saving time and money in the long run. In conclusion, steel pipes are a suitable choice for airport construction due to their strength, durability, versatility, corrosion resistance, and cost-effectiveness.

- Q: How are steel pipes used in the manufacturing sector?

- Steel pipes are commonly used in the manufacturing sector for various purposes, such as transporting fluids and gases, providing structural support, and facilitating the flow of materials in manufacturing processes. They are used in industries like construction, oil and gas, automotive, and aerospace for applications such as pipelines, machinery, conveyors, and infrastructure. Steel pipes offer durability, strength, and resistance to corrosion, making them an ideal choice for many manufacturing needs.

- Q: What is the composition of steel pipes?

- Steel pipes are primarily composed of iron and carbon, with small amounts of other elements such as manganese, silicon, and traces of sulfur and phosphorus.

- Q: Can steel pipes be used for conveying potable water?

- Indeed, steel pipes have the capability to convey potable water. Nevertheless, there are certain factors and precautions that necessitate consideration. Steel pipes possess strength and durability, rendering them suitable for the transportation of water across significant distances. They are also resistant to corrosion and capable of enduring high levels of pressure. In order to guarantee the safety and quality of the water being conveyed, it is crucial to employ pipes that have been specifically designed and manufactured for potable water applications. These pipes are often equipped with coatings or linings composed of materials that inhibit the leaching of contaminants into the water, such as epoxy or cement mortar lining. Furthermore, regular maintenance and inspections should be conducted to prevent the accumulation of sediments or rust that could potentially impact the water quality. It is important to acknowledge that steel pipes may prove more costly in comparison to alternative materials such as plastic or copper. Nevertheless, their longevity and reliability render them a cost-effective choice in the long run. Adhering to local regulations and standards concerning the utilization of steel pipes for conveying potable water is also imperative to ensure the well-being and safety of consumers.

- Q: What are the applications of steel pipes in the automotive industry?

- Steel pipes are widely used in the automotive industry for various applications such as exhaust systems, fuel lines, and structural components. These pipes provide durability, high strength, and resistance to corrosion, making them ideal for withstanding the harsh conditions and requirements of automotive applications. Additionally, steel pipes are lightweight, cost-effective, and offer excellent formability, enabling efficient manufacturing and design flexibility for automotive manufacturers.

- Q: Can steel pipes be used for hydropower generation?

- Yes, steel pipes can be used for hydropower generation. Steel pipes are commonly used in hydropower systems for various purposes such as penstocks and pipelines. Penstocks are large steel pipes that carry water from a reservoir to a turbine, where the force of the flowing water is converted into rotational energy. These pipes need to be strong and durable to withstand the high pressure of water and the weight of the structure. Additionally, steel pipes are also used for pipelines that transport water from the turbine back to the river or reservoir. Overall, steel pipes are an essential component in hydropower generation due to their strength, durability, and ability to withstand the harsh conditions of water flow.

- Q: How are steel pipes used in the manufacturing of food and beverage processing plants?

- Steel pipes are commonly used in food and beverage processing plants for various purposes such as transporting liquids, gases, and steam. They are used to create a network of pipelines that facilitate the movement of raw materials, ingredients, and finished products throughout the manufacturing process. Steel pipes are chosen for their durability, corrosion resistance, and ability to withstand high pressure and temperature conditions, ensuring the safety and efficiency of food and beverage production.

- Q: How are steel pipes used in the manufacturing of hydraulic systems?

- Steel pipes are commonly used in the manufacturing of hydraulic systems due to their durability, strength, and resistance to high pressures. These pipes are typically used to transport hydraulic fluid, providing a reliable and leak-free connection between various components such as pumps, valves, and actuators. Steel pipes also offer the advantage of being able to withstand harsh operating conditions and ensure efficient fluid flow, making them an essential component in hydraulic system manufacturing.

- Q: Can steel pipes be recycled after their useful life?

- Steel pipes can indeed be recycled once they have served their purpose. Steel, being an incredibly recyclable substance, can be recycled even in the form of pipes. The recycling of steel pipes entails the collection of used pipes, followed by thorough cleaning to eliminate any impurities, and finally transforming them into fresh steel products. This recycling process contributes to the preservation of natural resources, curbs energy usage, and limits waste generation. Moreover, recycling steel pipes aids in mitigating the environmental repercussions linked to the manufacturing of new steel.

Send your message to us

Carbon Seamless Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords