Seamless Round Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alloy Seamless Steel Pipe

1)OD:8-450mm

2)Thickness:1-60mm

3)MOQ: 25 tons

4)Material:A213 A335 A199, etc.

Alloy Seamless Steel Usage

Widly used in the general structure, mechanical structure with seamless steel tubes

Alloy Seamless Steel Pipe Grade

ASTM A519 1010-1045, 4130-4142, 5135

JIS G3441 SCM 415 TK, SCM 418 TK, SCM 420 TK, SCM 430 TK, SCM 435 TK, SCM 440 TK

JIS G3444 STKM 11A, STKM 12, STKM 13, STKM 14, STKM 15, STKM 16, STKM 17, STKM 18

STKM 19, STKM 20

BS 6323 CFS 3, CFS 3Aa, CFS 4, CFS 5b, CFS 6, CFS 7, CFS 8d, CFS 9, CFS 10, CFS 11

Alloy Seamless Steel Pipe Size

Outer Diameter Hot finish 2" - 30", Cold drawn 0.875" - 18"

Wall Thickness Hot finish 0.250" – 4.00", Cold drawn 0.035" – 0.875"

Length Random Length, Fixed Length, SRL, DRL

Alloy Seamless Steel Pipe Heat treatment

Annealed, Full Annealed, Bright annealed, , Spheroidize annealed

Normalized, Stress relieved, Cold finished, Quenched and Tempered

Alloy Seamless Steel Pipe Packing

Plastic plugs in both ends, Hexagonal bundles of max 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips

Alloy Seamless Steel Pipe Test

Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield

strength, Elongation), Technical Properties (Flattening Test, Flaring Test, Bending Test, Hardness Test, Blow Test, Impact Test etc), Exterior Size Inspection Mill Test Certificate EN 10204/31B

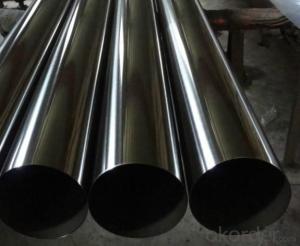

Alloy Seamless Steel Pipe Image

FAQ of Seamless Pipe

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard. If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: Who knows what is the difference between double submerged arc welded pipe and longitudinal submerged arc welding?

- The straight seam welding is relative to the spiral welding and the T-shaped welding, and so on.

- Q: How are steel pipes used in the manufacturing of bicycles?

- Steel pipes are commonly used in the manufacturing of bicycles as they provide strength, durability, and flexibility. They are used to create the frame, handlebars, and other structural components of the bike. The steel pipes are cut, shaped, and welded together to form the frame, providing a sturdy and reliable structure for the bicycle.

- Q: What are the different methods of protecting steel pipes from external damage?

- There are several methods of protecting steel pipes from external damage, including coating the pipes with a corrosion-resistant material such as epoxy or polyethylene, applying a layer of protective tape, installing a cathodic protection system, using concrete or rock shielding, and implementing measures to prevent soil movement or impact damage.

- Q: Can steel pipes be used for conveying hazardous chemicals?

- Yes, steel pipes can be used for conveying hazardous chemicals. Steel pipes are known for their high strength and durability, making them suitable for handling various substances, including hazardous chemicals. They can withstand high pressure and temperature, ensuring the safe transportation of these chemicals. Additionally, steel pipes have excellent resistance to corrosion, which is crucial when dealing with corrosive and potentially dangerous substances. Moreover, steel pipes can be easily welded and connected, allowing for a secure and leak-proof transport system. However, it is important to consider the specific requirements of the chemicals being transported and ensure that the steel pipes are properly designed, coated, and maintained to prevent any potential risks or reactions with the hazardous substances.

- Q: How do steel pipes handle soil movement?

- Steel pipes are highly resistant to soil movement due to their strength and durability. The rigid nature of steel pipes allows them to withstand ground shifting and settling without deforming or breaking. Additionally, steel pipes are often installed with proper anchoring and support systems to further enhance their ability to handle soil movement.

- Q: What are the different types of steel pipe connections for steam pipelines?

- There are several types of steel pipe connections commonly used for steam pipelines. These include threaded connections, flanged connections, welded connections, and grooved connections. Each type has its own advantages and is chosen based on factors such as the pipe size, pressure, and temperature requirements, as well as the ease of installation and maintenance.

- Q: How do you calculate the pipe buoyancy for steel pipes in water?

- To calculate the pipe buoyancy for steel pipes in water, you need to consider the weight of the water displaced by the submerged portion of the pipe. This can be done using Archimedes' principle, which states that the buoyant force on an object immersed in a fluid is equal to the weight of the fluid displaced by the object. First, calculate the volume of the submerged portion of the pipe. This can be done by multiplying the cross-sectional area of the pipe by the length of the submerged portion. Next, determine the density of the water in which the pipe is submerged. Typically, this value is around 1000 kg/m³ for freshwater and slightly higher for seawater. Multiply the volume of the submerged portion of the pipe by the density of the water to find the weight of the water displaced. Finally, compare the weight of the water displaced to the weight of the steel pipe. If the weight of the water displaced is greater than the weight of the pipe, the pipe will be buoyant and tend to float. If the weight of the pipe is greater, it will sink. It's important to note that other factors such as pipe design, wall thickness, and external forces acting on the pipe may also influence its buoyancy. Therefore, it's recommended to consult industry-specific guidelines or seek expert advice for accurate calculations in specific scenarios.

- Q: Can steel pipes be used for underground water supply pipelines?

- Yes, steel pipes can be used for underground water supply pipelines. Steel pipes are strong, durable, and resistant to corrosion, making them suitable for underground applications. They are often used for water supply pipelines due to their high strength and ability to withstand high pressure and load. Additionally, steel pipes can be welded together, ensuring leak-free connections, and are available in various sizes to accommodate different water supply needs.

- Q: How are steel pipes used in the construction of underground utilities?

- Steel pipes are commonly used in the construction of underground utilities due to their strength, durability, and resistance to corrosion. These pipes are typically used for water and gas distribution systems, as well as for sewer and drainage systems. The steel pipes are laid underground, serving as reliable conduits for the transportation of essential utilities to homes, businesses, and other structures.

- Q: Seamless steel pipe and welded pipe what is the difference?

- The welded pipe is made directly from the stainless steel band by machine, and it is made of round steel or perforated by Guan Pi

Send your message to us

Seamless Round Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords