Seamless Pipe ASTM A53 Standard For Steel Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 19000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1、Seamless Pipe ASTM A53 Standard For Steel Structure Description:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of Seamless Pipe ASTM A53 Standard For Steel Structure:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

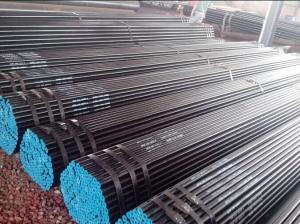

3、Seamless Pipe ASTM A53 Standard For Steel Structure Images:

Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

4、Seamless Pipe ASTM A53 Standard For Steel Structure Specification:

Standard | GB, DIN, ASTM |

Grade | 10#-45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1.Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2.Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3.Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4.Surface:black lacquered,varnish coating or galvanized.

5.Ends:Beveled or square cut,plastic capped,painted.

6.Packing:bundles wrapped with strong steel strip,seaworthy packing.

5、FAQ of Seamless Pipe ASTM A53 Standard For Steel Structure:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: Can steel pipes be used for underground cable conduits?

- Yes, steel pipes can be used for underground cable conduits.

- Q: How much is the tube?

- The theoretical weight calculation formula of ordinary carbon steel tube is:The weight of each meter is kg/m= (outer diameter mm-, wall thickness mm) * wall thickness mm*0.02466For example: inventory 20# pipe diameter of 108*4.5 weight per meter:Kg/m= (108-4.5) *4.5*0.02466=11.485In accordance with the diameter of 108*4.5 steel pipe market price is 4500 yuan / ton as an example, we can know the diameter of 108*4.5 steel pipe per meter price: 11.485*4.5=51.68 yuan.

- Q: How do you calculate the pipe flow velocity coefficient for steel pipes?

- The pipe flow velocity coefficient for steel pipes can be calculated using the Manning's equation. Manning's equation is used to calculate the flow velocity in open channels and pipes, and it takes into account the hydraulic radius, slope, and roughness coefficient of the pipe. To calculate the pipe flow velocity coefficient for steel pipes, follow these steps: 1. Determine the hydraulic radius (R) of the steel pipe. The hydraulic radius is calculated by dividing the cross-sectional area of the pipe (A) by the wetted perimeter (P). The formula is R = A/P. 2. Find the slope (S) of the pipe. The slope represents the change in elevation divided by the length of the pipe. It is usually given as a ratio or a percentage. 3. Determine the roughness coefficient (n) of the steel pipe. The roughness coefficient represents the internal roughness of the pipe and can be obtained from literature or pipe manufacturer specifications. It is commonly given in terms of the Manning's roughness coefficient. 4. Substitute the values of hydraulic radius (R), slope (S), and roughness coefficient (n) into the Manning's equation: V = (1/n) * R^(2/3) * S^(1/2) where V is the flow velocity. 5. Solve the equation for V to calculate the pipe flow velocity coefficient for steel pipes. It is important to note that the calculated velocity coefficient may vary based on the specific pipe dimensions, flow conditions, and other factors. Therefore, it is recommended to consult relevant engineering standards or consult with a hydraulic engineer to ensure accurate and reliable calculations for specific applications.

- Q: How do steel pipes handle thermal expansion and contraction?

- Steel pipes are able to handle thermal expansion and contraction due to their unique properties and design. When exposed to high temperatures, steel pipes expand as the molecules within the material gain energy and move more vigorously. Conversely, when exposed to low temperatures, steel pipes contract as the molecules lose energy and move less vigorously. To accommodate these changes, steel pipes are manufactured with certain features. One such feature is the allowance of clearance between pipe joints. This clearance allows for expansion and contraction without causing stress or deformation in the pipe. Additionally, the use of expansion joints or flexible connectors within the piping system helps to absorb the thermal movements and prevent damage. Furthermore, steel pipes are often installed with proper anchoring and support systems. These systems are designed to allow the pipes to freely expand and contract within a certain range without causing excessive stress or strain on the structure or surrounding components. Anchoring and support systems also help to maintain the overall stability and integrity of the piping system. In some cases, thermal insulation materials are applied to steel pipes to minimize temperature changes and reduce the effects of expansion and contraction. These insulating materials help to maintain a more consistent temperature within the pipe, reducing the magnitude of thermal movements. Overall, steel pipes are well-suited to handle thermal expansion and contraction due to their inherent strength and flexibility. With proper design, installation, and maintenance, steel pipes can effectively accommodate temperature changes without compromising their structural integrity or functionality.

- Q: Are steel pipes suitable for use in sewage treatment plants?

- Yes, steel pipes are suitable for use in sewage treatment plants. Steel pipes are durable, corrosion-resistant, and can withstand high-pressure applications, making them an ideal choice for transporting and containing sewage in treatment plants. Additionally, steel pipes can be easily welded, allowing for seamless connections and minimizing the risk of leaks or contamination.

- Q: How are steel pipes used in the manufacturing of chemical processing plants?

- Steel pipes are commonly used in chemical processing plants for various purposes, such as transporting fluids and gases, as well as providing structural support. They are highly resistant to corrosion, making them ideal for handling corrosive materials in the plant. Additionally, steel pipes can withstand high temperatures and pressure, ensuring the safe and efficient operation of chemical processes.

- Q: How can two smooth steel pipes be joined? The size of the two pipe is different (except for welding)

- Butt fastener: used for connecting two steel pipe jointsThin-walled stainless steel pipe, the national standard consists of three parts, respectively on the thin stainless steel pipe connection, the sealing ring of raw materials of various specifications of O type thin wall stainless steel pipe diameter and wall thickness of pipe and rubber have clear requirements, in order to ensure the quality of the whole pipeline, pipeline safety and guarantee system durability. The connection mode is clamp type and ring type.

- Q: Galvanized steel pipe DN100 and SC100

- DN is the meaning of "bore", also expressed in water supply and drainageSC is welded steel pipe, generally GB tube, that is, thick walled steel pipe, look at the design requirementsMT refers to the wire tube, usually thin-walled tube, there are KBG and JDG

- Q: What's wrong with the 3PP anticorrosive steel tube?

- PP and PE are similar in processability, and the 3PE coating can be used to produce 3PP coatings without the need for a special 3PP coating line. However, the difference between PP and PE materials makes the 3PP and 3PE coatings show different properties, which can be applied to different environments. The advantages of 3PP coating on some properties make it possible to play an important role in the field of 3PE coating. Therefore, many foreign pipeline projects use 3PP anticorrosive coating.

- Q: Can steel pipes be used for drainage systems?

- Yes, steel pipes can be used for drainage systems. Steel pipes are durable, strong, and resistant to corrosion, making them suitable for various applications, including drainage systems. They can effectively transport water and waste materials, ensuring efficient drainage.

Send your message to us

Seamless Pipe ASTM A53 Standard For Steel Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 19000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords