screw conveyor 323

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Screw Conveyor is a new conveyor equipment, commonly known as "auger”, It’s an ancillary equipment, commonly used in mixing station (concrete batching plant), mainly used for mixing station (concrete batching plant) powder conveying. Also be used as the transport equipment to use in other industries (which require special order), such as supporting brick equipment.

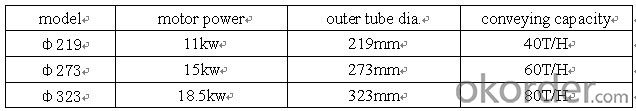

The screw conveyor is our company produce, main components includes motor, gear box, outer pipes, lifting shaft, blades, tail bearings, universal joints (global), inlet flange, charging port, observation window and other parts. A variety of connection ports can be used for charging and discharging port, such as universal global connection, flange connection, or bag lifting connection, and many more convenient, optional. Conventional model includes: φ168, φ219, φ273, φ325, etc. Length and angle can be customized according to customer’s specific requirements.

- Q: What raw materials and equipment do you need for your own admixture?

- The admixture of concrete mixing station using a lot of more phyletic, the effect is different also, early strength agent, retarder, water reducing agent, and release agent, antifreeze, etc., which is a kind of do not know you to call. The admixtures are usually made by professional manufacturers, and the ingredients are not the same.

- Q: The main components of a mixing station

- Feeding system: aggregate bucket, aggregate weighing hopper, flat belt machine, inclined belt conveyor. Mixing system: the main machine is a double-deckshaft mixer, reducer, cement weighing hopper, water and additive weighing hopper. Cement supply system: cement warehouse, screw conveyor, air compressor, screw electronic. Automatic water supply system: water tank, pump, pipe. Electrical operating system: computer console, electric control cabinet, operation room. Operation control system: microcomputer control or manual control.

- Q: What are the supporting facilities for the concrete mixing stations?

- Mixing station can be divided into single and double machine stand, as the name implies, stand-alone station each station has a mixing console, the double machine station has two mixing console, each mixing console has a discharging mouth, so double machine mixing plant is a stand-alone station 2 times of production capacity.

- Q: What constitutes the js750 concrete mixing station

- Host one, silo (usually four kinds of material), a set of mainframes, three to four storage tanks (with a cage), and an air compressor, which is usually the case

- Q: What are the ingredients for the concrete mixing stations?

- It is the raw materials for the concrete mixers, the sand, stone, cement, fly ash, mineral powder, various admixtures, water, basically these seven raw materials.

- Q: What are the facilities of the concrete mixing station

- One. Stir the host The mixing machine is divided into strong mixing and self-falling stirring. The powerful mixer is the mainstream in the domestic and foreign mixers, it can stir the liquid, semi-dry hard and hard and so on. The main mixing liquid concrete of the self-falling mixer is very rarely used in the mixing station. Two. Material transport system The material transport consists of three parts. Aggregate conveying; There are two ways of conveyance and belt conveyance. The advantage of hopper promotion is that the area is small and the structure is simple. The advantage of belt transport is that the transport is large, efficient and low. The belt conveyor mainly applies to the mixing stations that have aggregate storage, thereby increasing the productivity of the mixing stations. Powder conveying; The powder used in concrete is mainly cement, fly ash and mineral powder. The most commonly used powder conveyors are conveyors of screw conveyors, and the large mixing buildings are carried by pneumatic conveyer and scraper. The advantages of screw transport are simple structure, low cost and reliable use. Liquid transport mainly refers to water and liquid admixtures, which are delivered separately by water pumps.

- Q: What is the special work of the concrete mixing station

- The ratio of the concrete particles to the surface area, the shape of particles, the density of the particles and the grading of the particles, etc., are very important to the liquidity of the slurry. Smaller than surface area, the particle shape is closer to the ball, bigger, more filling and more liquid. By optimizing these factors, you can obtain the most appropriate liquidity. In order to design the concrete mix according to the engineering requirement, the characteristics of the aggregate material must be mastered first. The properties of aggregates are determined by factors such as microstructure, prior exposure and processing, and these factors influence the properties of fresh and hardened concrete. The effect of aggregate properties on concrete performance should be considered, and the quality of concrete mixing equipment should be considered. Before installation, check the appearance quality of the equipment again, the platform bolts are not loose, the welding seam is not cracked, the oil leak, the water, the ash (the lump), etc. Clean the assembly of the whole machine and re-spray paint, rust and renovate. Prepare the all kinds of bolts, welding wire, iron plate, etc., to prepare tools and protective equipment, the use of more tools for several sets of parts can use pneumatic wrench, and provide timely acetylene cutting, electric welding equipment; Plan the entry time of the crane.

- Q: The average commodity concrete is mixed with a day to use how much fly ash

- What is the amount of cement in the concrete mixing station? This is based on the different levels of the concrete mix. Here is a different grade of concrete ingredients: Note: 1. The mix of concrete and concrete shall be carried out in uniform ratio of gravel and slump. In one project, the C40 is mixed with ordinary cement, and according to the proportion design, the maximum amount of coal ash can replace 40% of the cement consumption.

- Q: Which staff does the concrete mixing station need?

- Move the cement iron pipe, driver! technology, webmaster, laboratory (deputy) director of the general, production manager, sales managers, salespeople, scheduling, lab team leader, the operator (inspection), quality inspection, proportioning design, the material inspector technicians,

- Q: Does the concrete mixing station name have the name of the businessman concrete

- Original concrete is the construction unit oneself mix, the existing specialized manufacturer presses the need to produce concrete, the product that produces is concrete.

Send your message to us

screw conveyor 323

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords