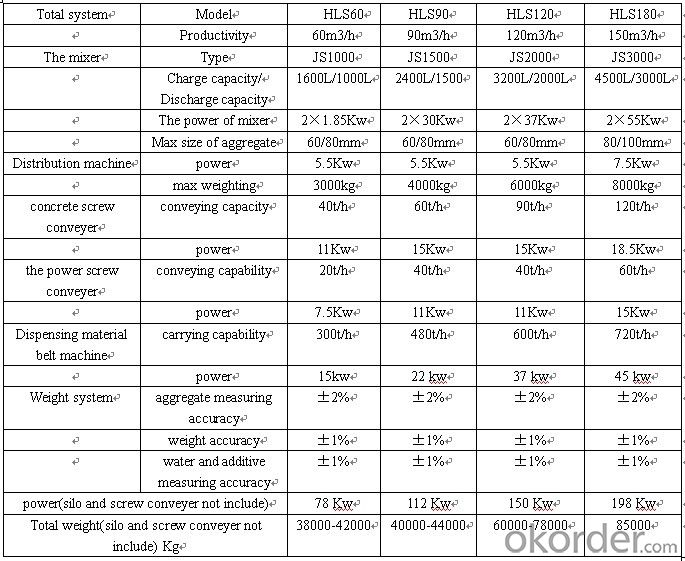

HLS 120 concrete batching plant

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

The station is the large concrete mixing equipment integrating the storage, metering, and mixing of materials. The height of concrete discharges is 3.8m. It can mix various types of concrete, and is especially suitable for mixing dry and hard concrete, which is applicable for at least medium-sized construction engineering, water and electricity, roads, ports, docks, bridges and other projects as well as larger and medium-sized manufacturing factories and concrete production plants.

The storage silo of this equipment series is of linear arrangement, and charging is realized via loaders. It is possible to store four kinds of aggregates at one time. The aggregate measurement is conducted on the ground. The measured materials are delivered to the aggregate hopper on the roof through flat or inclined belts. The aggregate storage hopper can store a can of measured aggregates. According to users’ needs, the powder dosing system can be equipped with three cement silos and one fly ash silo. Three kinds of powders are measured respectively by spiral conveyor to the bucket. The water and liquid additives flow out of the pump into the bucket. The process is controlled by computer, and electronic scales are used for measurement, with high precision and minor error. The products are equipped with a screen display, dosing storage, automatic drop compensation, sand moisture rate compensation and other functions (sand moisture rate meter should be ordered separately), as well as a manual system, which realize manual and automatic control in the process of mixing. In addition, the equipment is completed with a printing system, and a monitoring system, to realize centralized control and integrated management of the equipment.

- Q: What is the concrete of the mixing station?

- I am at the work station, the concrete mixing plant is operating goods, use the material such as cement, fly ash, sand, water reducing agent in strict accordance with the provisions of the state standard the ratio of mixing, through concrete truck mixer (commonly known as "car" river) transportation to the construction site, recycled concrete pump for handlebar concrete on the building site. For building products safety, now the big building construction are banned to mix concrete, concrete supply must to the recognition of concrete mixing station to buy, hope to help you.

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- If it's a theoretical one, it's going to build 90 lines per hour, which is 90 square hours per hour, and if it's actually 90 square, it's going to be at least 120 stations.

- Q: What are the supporting facilities for the concrete mixing stations?

- The facilities include concrete mixing equipment, concrete transportation equipment, experimental equipment, forklift truck, over-pound equipment, pump, and car pump etc. Concrete mixing station is mainly composed of mixing console, materials weighing system, material conveying system, material storage system and control system of large system and other ancillary facilities. Because building aggregate measurement compared with standing aggregate metering, reduced the four of the intermediate links, and the vertical blanking metering, saved measuring time, thus greatly improving the production efficiency, under the condition of the same model, mixing building production efficiency than mixing plant production efficiency by a third. Such as: HLS90 floor of production efficiency and production efficiency of HZS120 stand HLS120 floor of the production efficiency, production efficiency is equivalent to HZS180 stand HLS180 floor of the production efficiency is equivalent to the productivity of HZS240 station. Concrete mixers are a combination of concrete and concrete prefabrication. Because its mechanization, high degree of automation, productivity is high, and can guarantee the quality of concrete and cement, commonly used in concrete, long duration and site of quantities focus of large and medium-sized water conservancy, electric power, Bridges and other projects. Centralized with the development of municipal construction, stirring, provide commercial concrete mixing station has great advantages, and thus get rapid development, and to promote concrete pumping construction, the mixing, transportation, casting machinery joint operation to create the conditions.

- Q: How much water does a concrete mixer use every day?

- Water is an indispensable part of the concrete production industry. As an investment company in a concrete mixing station, it is also important to have control over water use. It is also an aspect of production cost control. The use of water used in concrete stations is not the main water link. Flush the blender and cement truck every day to use a lot of water. The concrete is very difficult to handle because of the condensation. So it is the most effluent project in the production standstill. And the washings of these rinsing equipment contain water slurry, aggregates and aggregates, etc. From the environmental point of view, the water of cement mortar or concrete is strong alkaline, the PH value is high, can reach about 12, free discharge can pollute the environment. Therefore, with the continuous improvement of the environmental requirements in recent years, the waste water treatment of the mixing station becomes the main concern.

- Q: How to choose a good concrete mixer station?

- Selection is best good survey is supply and demand situation of you and how many mixing station, concrete demand how, don't blindly pursuing big equipment, vehicles and personnel left unused, but it is now generally good, as long as the operation, mixing station not at a loss

- Q: What constitutes the js750 concrete mixing station

- The concrete mixing station consists of the mixing system, the aggregate supply system, the measuring system, the control system and the external supporting equipment. The main purpose of the mixing station is to mix concrete, also called concrete mixing station. HZS series products adopt international popular cement concrete mixing station quickly assembled module type structure, high-performance imported agitator, double machine double control way of computer control, prevent noise, prevent dust pollution, environmental design, is the new generation of cement concrete mixing equipment, applicable to urban commodity ready-mixed concrete, road and bridge, water conservancy, airports, ports and other large infrastructure construction project and concrete demand for large sites.

- Q: What are the facilities of the concrete mixing station

- The concrete mixing station consists mainly of five major systems, such as mixing main, material conveying system, material weighing system, material storage system and control system

- Q: What are the advantages of HZS series of concrete mixing stations

- HZS75 concrete batching plant investment amount, less occupied area is small, the use of equipment, maintenance easy, can be equipped with high performance of independent control room, make the equipment operation convenient and safe, and in the batching machine also can produce high quality under the condition of accurate measurement of concrete. This type of mixing station under our positive study also used the green environmental protection design, the construction of a possible pollution under control, rather than the old way of construction and transportation pollution, nature is winning.

- Q: What is the special work of the concrete mixing station

- The ratio of the concrete particles to the surface area, the shape of particles, the density of the particles and the grading of the particles, etc., are very important to the liquidity of the slurry. Smaller than surface area, the particle shape is closer to the ball, bigger, more filling and more liquid. By optimizing these factors, you can obtain the most appropriate liquidity. In order to design the concrete mix according to the engineering requirement, the characteristics of the aggregate material must be mastered first. The properties of aggregates are determined by factors such as microstructure, prior exposure and processing, and these factors influence the properties of fresh and hardened concrete. The effect of aggregate properties on concrete performance should be considered, and the quality of concrete mixing equipment should be considered. Before installation, check the appearance quality of the equipment again, the platform bolts are not loose, the welding seam is not cracked, the oil leak, the water, the ash (the lump), etc. Clean the assembly of the whole machine and re-spray paint, rust and renovate. Prepare the all kinds of bolts, welding wire, iron plate, etc., to prepare tools and protective equipment, the use of more tools for several sets of parts can use pneumatic wrench, and provide timely acetylene cutting, electric welding equipment; Plan the entry time of the crane.

- Q: What is the difference between a concrete mixer and a concrete mixer

- The bone material of the mixing tower is on the top, and the aggregate is measured directly into the mixer. The concrete bin of the commercial concrete station is below, and the bone material is measured and then transported into the mixer after being transported by the inclined belt (which also has some use of the elevator). In a popular way, it is called the building, which is called the second ascent. The steel structure will be larger and the diagonal belt will be relatively longer because of the bone material in the mixing building. But in productivity, the churn is about a fifth higher than the commercial concrete station. In operation, because the inclined belt of the commercial concrete station starts frequently, the energy consumption and the failure rate will increase, and the energy consumption of the mixing building is lower than the failure rate. In the end, because the production capacity of the concrete station is small, the structure is easily disassembled and can be made into a container transfer site, which is suitable for the construction site. The mixing tower is large and high in productivity, and can only be used as a fixed mixer, suitable for the supply of large water projects or large quantities of goods. So customers in the difference between commercial concrete, concrete stand and commodity concrete mixing floor, from aggregate (material), the production efficiency and so on, to choose and buy the right equipment.

Send your message to us

HLS 120 concrete batching plant

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords