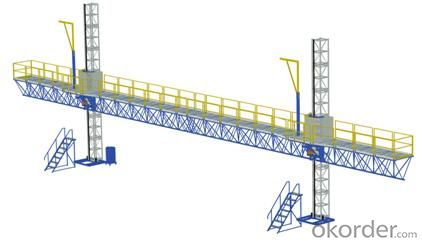

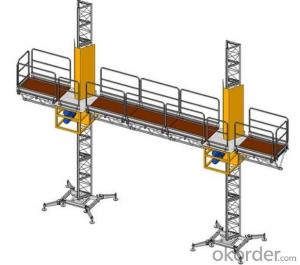

SCP200 double mast Climbing Work Platform

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 15 units unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SAFETYFEATURES

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

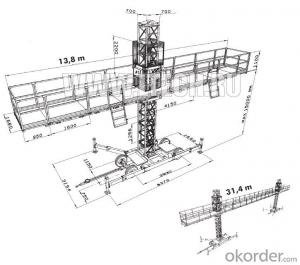

Rated Capacity | 2000 kg, Double Mast |

Maximum Length of Platform | 25m |

Width of Platform | 1200 mm |

Length of Platform Section | 1500 mm |

Length of basic platform Section | 1080 mm |

Length of extension platform | 1000 mm Extension tubes and floor included |

Height | 200 m |

Lifting Speed | 0-6 m/min, with frequency inverter, Toshiba Brand |

Motor Power | 2-2x2.2kw, SEW Motor + Reducer |

Mast Section | Square 450mm × 450mm × 1508mm; Square Tube 60 x 60mm, Thickness 4mm & 6mm Module = 8 Hot dip galvanized |

Voltage | 380-415 [V] - 50 -60 [Hz] |

Centrifugal Safety Device Model | SAJ30-0.8 |

Noise Level | ≤60 dB |

- Q: This question asks for a comparison between lifting equipment used in indoor settings versus those used outdoors, focusing on their differences.

- <p>Indoor lifting equipment is designed for controlled environments, often smaller and more precise, with features like electric chain hoists or jib cranes. They are typically quieter, require less maintenance, and are suitable for tasks like assembly, manufacturing, and warehouse operations. Outdoor lifting equipment, such as gantry cranes or mobile cranes, is built to withstand harsh weather conditions, has higher load capacities, and is often used for construction, shipping, and heavy industry. These are more robust, may require more maintenance, and are designed for larger, heavier loads over uneven terrain.</p>

- Q: This question asks for an explanation of the working mechanism of a building hoist, which is a device used in construction to lift materials and workers.

- <p>A building hoist, also known as a construction hoist or personnel/material hoist, is a temporary lifting device used in construction projects to transport workers and materials vertically within a building. It typically consists of a tower, a cage, a drive mechanism, and a control system. The tower is attached to the building's structure, and the cage is where people or materials are loaded. The drive mechanism, often powered by an electric motor, raises and lowers the cage along the tower. The control system manages the movement, ensuring safety features like speed control and emergency stops are in place. The hoist operates within a guide rail system, which keeps it aligned as it moves up and down the building's height.</p>

- Q: Why is the construction elevator open on one side and the other on the other

- Double door is feeding door, double door to the outside of the other's role is to prevent someone broke into the cage after elevator start circle accident, because outside over the door of the cage has a travel switch, when someone will ring into the cage opened the cage door, travel switch action at this moment, the elevator power cuts, you won't get elevator lay down this kind of thing. The door is open only when the lift is off the ground, as is said upstairs.

- Q: This question asks about the procedures and practices for regularly maintaining and inspecting a building hoist to ensure its safe and efficient operation.

- <p>Regular maintenance and inspection of a building hoist are crucial for safety and efficiency. It involves daily checks before use, including visual inspections for any visible damage, proper functioning of safety devices, and ensuring the hoist is clean and free of debris. Weekly inspections should focus on the mechanical components, such as gears, cables, and brakes, and checking for any unusual noises or vibrations. Monthly inspections may include more in-depth checks of the electrical systems and the structural integrity of the hoist. Annual inspections typically involve a thorough examination by a certified professional, who will assess the overall condition and safety of the hoist, ensuring it complies with all relevant safety standards. Always follow the manufacturer's guidelines and local regulations for maintenance and inspection schedules.</p>

- Q: This question asks if a building hoist can be utilized for lifting both light and heavy objects.

- <p>Yes, a building hoist can be used for lifting both light and heavy objects. It is designed to handle a wide range of weights, depending on its capacity. Building hoists are engineered to lift materials such as bricks, concrete, and steel beams during construction. However, it's crucial to ensure that the hoist's lifting capacity is not exceeded to avoid accidents. Always check the manufacturer's specifications and safety guidelines before lifting any object with a building hoist.</p>

- Q: Safety device for construction elevator

- 1. The governor To prevent the hanging basket construction elevator overspeed or fall and set up a safety device, is divided into a unidirectional and bidirectional type two kinds, the one-way speed limiter can only along the direction hoisting cage falling within the speed limit, two-way speed limiter can up and down along the hoisting cage speed effect on two directions. The speed limit shall be tested for performance in accordance with the prescribed time limit. 2. The buffer spring Buffer spring in spring seat connected to the base frame, so that when hanging cage fall accidents, reduce the impact of the hanging basket, at the same time ensure crane cage and weight drops landed into flexible contact, slow down the hoisting cage and the impact of weight landing. The buffer spring has a cone winding spring and a cylindrical spiral spring. Usually, there are two or three cone coiled springs or four cylindrical coils on the base of each cage.

- Q: This question asks for measures to avoid accidents that may occur due to the misuse of a building hoist.

- <p>To prevent accidents caused by improper use of a building hoist, it's crucial to follow safety protocols strictly. Ensure all hoist operators are trained and certified. Regularly inspect and maintain the hoist equipment to check for any defects or wear. Never overload the hoist, and always secure the load properly. Implement clear communication procedures among workers, especially when the hoist is in operation. Set up barriers or warning signs to keep unauthorized personnel away from the hoist area. Finally, conduct regular safety drills to prepare for emergencies and reinforce safety practices among the workforce.</p>

- Q: Is it possible to utilize alternative lifting equipment in place of a building hoist for specific tasks?

- <p>Yes, for certain tasks, alternative lifting equipment can be used instead of a building hoist. Cranes, forklifts, and telescopic handlers are common substitutes. The choice depends on the task's specific requirements, such as the weight of the load, the height to which it needs to be lifted, and the available space. Each piece of equipment has its own advantages and limitations, so it's crucial to select the appropriate one based on the project's needs to ensure safety and efficiency.</p>

- Q: Is it possible to utilize building hoists for construction purposes?

- <p>Yes, building hoists are commonly used in construction work. They are essential for lifting and lowering materials, tools, and sometimes personnel between different floors of a building under construction. These hoists enhance efficiency by reducing manual labor and improving safety by minimizing the risk of accidents associated with manual handling of heavy loads. They are designed to be robust and reliable, making them a vital piece of equipment in the construction industry.</p>

- Q: Is it possible to utilize a building hoist for the transportation of heavy objects?

- <p>Yes, a building hoist is specifically designed to move heavy objects within a construction site or in similar environments. It is a type of crane that can lift and lower materials vertically, making it ideal for transporting heavy items such as construction materials, machinery, and equipment. Building hoists are engineered to handle significant weight loads and are an essential tool for efficient material movement in vertical construction projects.</p>

Send your message to us

SCP200 double mast Climbing Work Platform

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 15 units unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords