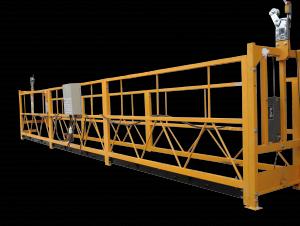

Suspended Platform ZLP250

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set m.t.

- Supply Capability:

- 300Sets Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZLP250 Suspended Platform

ZLP series Suspended Platform (temporarily installed suspended access equipment), is ideal equipment for building facade construction, decoration, cleaning and

maintenance. And it is also widely used in elevator installing, ship building and repairing, or in other works such as big-size tank, bridge, embankment and chimney. ZLP series

versatile knock-down platforms provides workers safer, easier and more efficient platform access.

Specification OF ZLP250:

Model | ZLP250 | ||

Rated capacity | 250 kg | ||

Rated speed | 9-11 m/min | ||

Steel rope | 4T31 | ||

Hoist | Hoist model | LTD6.3 | |

Rated lifting force | 6.3 KN | ||

Motor | Model | YEJ90L-4 | |

Power | 1.5 KW | ||

Phase | 3 Phase | ||

Speed | 1420 r/min | ||

Brake force moment | 15 Nm | ||

Safety lock | Configuration | Centrifugal | |

Permission force of impact | >800kg | ||

Locking Cable Distance | <100mm | ||

Counter-weight | 450kg | ||

- Q: Is it possible to use a building hoist for lifting delicate or fragile items?

- <p>A building hoist is typically designed for heavy construction materials and not recommended for lifting fragile objects. The vibrations and force exerted during lifting can damage delicate items. For fragile objects, specialized hoists or cranes with controlled movements and gentle handling capabilities are advised to ensure safety and prevent damage.</p>

- Q: Is it possible to utilize a building hoist for elevating construction materials?

- <p>Yes, building hoists are commonly used in construction to lift materials. They are designed to transport heavy materials, such as bricks, cement, and steel, vertically between floors. These hoists are crucial for efficient construction, especially in high-rise buildings, as they reduce manual labor and increase safety by minimizing the need for workers to carry heavy loads up ladders or stairs.</p>

- Q: What about the energy efficiency of the escalator

- Variable frequency construction elevator energy saving effect general. Frequency conversion is not energy efficient. The difference between the frequency and the common machine is the smoothness and speed of the operation. Frequency conversion speeds up to 90m / 1 minutes and the average is only 35m / 1 min Frequency conversion when parking is slow down and stop Ordinary is directly stop delay parking and adjustment made door light who bow Angle decyl with brush spring connection will be better. The frequency conversion requires the site voltage to be strictly a little bit looser than the voltage requirement Energy consumption is: according to the elevator drive mechanism for general three transmission two kinds of the elevator are three 11 kw motor, that their energy consumption are 3 x 11 = 33 kw is hours each hanging basket consumes electricity 33 degrees, the actual power consumption will be bigger.

- Q: Why is the construction elevator open on one side and the other on the other

- Open the door, commonly known as the feed door, usually open up, and add weights to both sides. Only if the construction ladder stops at the bottom. If the door is double open, the room must be left with half a door (> 1.3 m) to open the door completely. If it is a single open door that opens up, you can save space in the cage. Double door, namely, two doors, either up or down, the two doors balance weight. It usually arrives on the required floor. There is enough room for double doors.

- Q: Can a building hoist experience technical issues or fail to operate properly?

- <p>Yes, a building hoist can malfunction. Like any mechanical system, hoists are subject to wear and tear, component failure, and can be affected by human error. Malfunctions may include mechanical breakdowns, electrical faults, or safety device failures. Regular maintenance, inspection, and adherence to safety protocols can reduce the risk of hoist malfunctions.</p>

- Q: This question asks for a comparison of various types of electric building hoists, highlighting their unique features and differences.

- <p>Electric building hoists come in various types, each designed for specific applications. The main differences lie in their capacity, lifting speed, control systems, and construction. For instance, worm gear hoists are compact and offer precise control, suitable for light to medium-duty applications. Chain hoists are versatile with higher speeds and are ideal for general lifting tasks. Electric wire rope hoists are powerful and designed for heavy-duty lifting, often used in construction and industrial settings. Variable frequency drives in hoists allow for speed control, enhancing safety and efficiency. Each type has its operational advantages and limitations, making the choice dependent on the specific lifting requirements and environmental conditions.</p>

- Q: This question asks for a comparison between electric and electric-hydraulic building hoists, highlighting their distinct features and how they differ from each other.

- <p>Electric building hoists are powered solely by electric motors, which provide direct and precise control over the lifting and lowering of loads. They are quieter, require less maintenance, and are more energy-efficient compared to their hydraulic counterparts. On the other hand, electric-hydraulic building hoists combine the power of an electric motor with the force amplification capabilities of hydraulic systems. These hoists offer greater lifting capacity and can handle heavier loads but are generally more complex, requiring regular maintenance of hydraulic components. They are also louder and may consume more energy. The choice between the two often depends on the specific requirements of the lifting task, such as load capacity, precision, and environmental considerations.</p>

- Q: Is it possible to utilize a double-rope lifting mechanism within the context of a building hoist?

- <p>Yes, a double-rope lifting system can be used in a building hoist. This system offers advantages such as increased safety due to redundancy and the ability to lift heavier loads compared to a single-rope system. The double-rope setup allows for the hoist to handle the load with two separate ropes, reducing the risk of failure and providing a more stable lifting platform. It's common in applications where high load capacities and safety are paramount, such as in construction for lifting materials and equipment.</p>

- Q: Is it possible to utilize alternative lifting equipment in place of a building hoist for specific tasks?

- <p>Yes, for certain tasks, alternative lifting equipment can be used instead of a building hoist. Cranes, forklifts, and telescopic handlers are common substitutes. The choice depends on the task's specific requirements, such as the weight of the load, the height to which it needs to be lifted, and the available space. Each piece of equipment has its own advantages and limitations, so it's crucial to select the appropriate one based on the project's needs to ensure safety and efficiency.</p>

- Q: This question is asking for a comparison between electric and hydraulic building hoists, focusing on their differences.

- <p>Electric and hydraulic building hoists differ primarily in their power source and operational mechanisms. Electric hoists use electric motors to lift and lower loads, which makes them more energy-efficient and quieter in operation. They also tend to have fewer maintenance requirements and are often easier to control with precise movements. Hydraulic hoists, on the other hand, use hydraulic pressure to move loads and are known for their ability to lift heavy loads with less effort. They are often preferred for applications requiring high lifting capacities and can be more compact. However, hydraulic hoists may require more maintenance due to the presence of seals and fluid systems, and they can be noisier than electric hoists.</p>

Send your message to us

Suspended Platform ZLP250

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set m.t.

- Supply Capability:

- 300Sets Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords