Scotch Clear Packaging Tape - PVC Electrical Insulation Tape Low Price Excellent Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Tape

PVC tapes are made of soft pvc film coated with rubber pressure-sentitive adhesive.

Application of PVC Tape

PVC tapes are widely used in auto harness, wrapping of wire, and insulation protection. It is the main insulation material of automobilehousehold electrical apparatus.

Advantage of PVC Tape

Corrosion protection for metal piping systems above and below ground.

Corrosion protection for fittings and joints on mill coated pipe.

Corrosion protection of electrical conduit & fittings.

Resists corrosive action by salt water, soil acids, alkalies and salts.

Prevents dielectric corrosion between buried steel pipe and soil minerals.

Pictures of PVC Tape

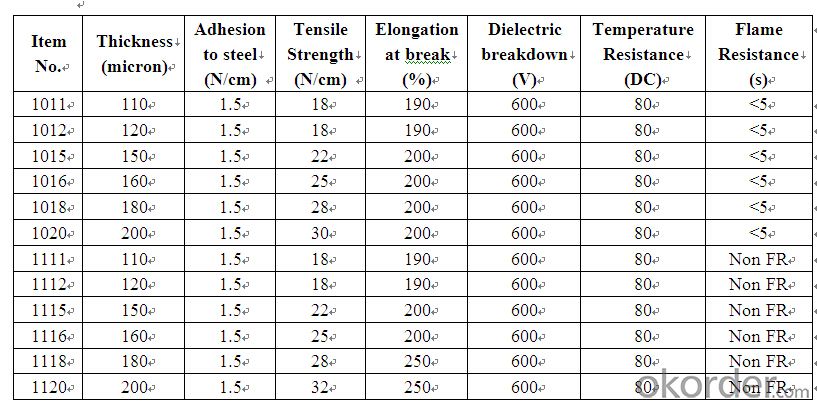

Specification of PVC Tape

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

- Q: Are there any regulations or standards for packaging tape?

- Yes, there are regulations and standards for packaging tape. These guidelines typically cover aspects such as strength, adhesion, durability, and safety. Organizations like ASTM International and the International Organization for Standardization (ISO) have developed standards to ensure that packaging tapes meet certain quality and performance requirements. Additionally, regulatory bodies in different countries may have specific regulations for packaging materials, including tapes, to ensure they are safe for use and compliant with applicable laws.

- Q: How do I remove packaging tape without damaging the surface?

- To remove packaging tape without damaging the surface, you can try using a hairdryer to gently heat the tape, which will make it easier to peel off. Alternatively, you can use a small amount of rubbing alcohol or vinegar to dissolve the adhesive before carefully peeling it off. It's important to be patient and take your time to prevent any potential damage to the surface.

- Q: How does packaging tape perform on high-friction surfaces?

- Packaging tape is specifically designed to stick to various surfaces, including those with high friction. The tape's ability to adhere to high-friction surfaces may vary depending on the specific type of tape and the surface it is applied to. In general, packaging tape has a strong adhesive that allows it to securely stick to surfaces, even those with high levels of friction. The tape's adhesive is formulated to provide excellent tackiness and bonding strength, ensuring that it remains in place and maintains its hold on high-friction surfaces. However, it is important to note that excessive friction or roughness on a surface can potentially impact the tape's ability to stick. If the surface is extremely rough or uneven, it may create air pockets or gaps between the tape and the surface, which can compromise its performance. In such cases, it is recommended to properly prepare the surface by cleaning and smoothing it before applying the tape to ensure optimal adhesion. Furthermore, the durability of the tape can also affect its performance on high-friction surfaces. Some packaging tapes are reinforced with fibers or have a thicker construction, making them more resistant to wear and tear caused by friction. These tapes are often recommended for heavy-duty applications or when packaging items that will experience constant rubbing or sliding on high-friction surfaces. Overall, packaging tape is generally well-suited for use on high-friction surfaces. By considering the tape's adhesive properties, properly preparing the surface, and selecting an appropriate tape, reliable and long-lasting adhesion can be achieved, even in challenging conditions.

- Q: Does packaging tape come in different lengths for convenience?

- Packaging tape indeed comes in various lengths for ease of use. Different packaging tasks can be accommodated with packaging tape of different lengths. The commonly found lengths for packaging tape are 55 yards (50 meters) and 110 yards (100 meters). These lengths are specifically chosen to address diverse packaging needs and to ensure that there is an ample amount of tape to securely seal multiple packages without any shortage. Furthermore, the availability of different lengths provides the flexibility of selecting the most appropriate quantity of tape for individual packaging requirements, ensuring both convenience and cost-effectiveness.

- Q: What course of packing and cartons do we use for our company?

- The raw material accounts for all the materials in the inventory of the enterprise, including the planned costs and actual costs of raw materials and main materials, auxiliary materials, purchased semi-finished products, repair parts, packaging materials, fuels, etc..

- Q: Does packaging tape come in different colors?

- Packaging tape indeed comes in various colors. Although clear is the most commonly used color, there is a wide range of colors to choose from to cater to different requirements and personal preferences. For instance, red, blue, green, yellow, and black are some examples of colored packaging tape. These colored tapes serve multiple purposes, such as color-coding packages, indicating priority shipments, or adding a vibrant touch to your packaging. Moreover, colored packaging tape offers versatility as it can be used for decorative or artistic intentions, making it a suitable choice for both practical and creative uses.

- Q: Does packaging tape come in different colors for organization purposes?

- Yes, packaging tape does come in different colors for organization purposes.

- Q: Can packaging tape be used for sealing pharmaceutical or medical supplies?

- Yes, packaging tape can be used for sealing pharmaceutical or medical supplies. However, it is important to ensure that the tape is compatible with the specific requirements of the supplies and adheres securely to maintain proper hygiene and prevent contamination.

- Q: How wide is standard packaging tape?

- The usual width of standard packaging tape is around 2 inches.

- Q: Is packaging tape safe to use on plastic hangers?

- Yes, packaging tape is generally safe to use on plastic hangers. It adheres well to most surfaces, including plastic, and provides a secure hold. However, it is recommended to use a moderate amount of tape to avoid damaging or leaving residue on the hangers.

Send your message to us

Scotch Clear Packaging Tape - PVC Electrical Insulation Tape Low Price Excellent Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches