SCM440 Forged or Hot Rolled Sae 4140 Alloy Steel Round Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 123 m.t.

- Supply Capability:

- 2005544 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of steel round bar:

1. Commodity: Round steel bar

3. Technical: Hot rolling

2. Length: Min. 5.8meter, according to requirement.

3. Diameter: 16mm-250mm

5. Packing: In Bundle or according to your requirements.

Festures of steel round bar:

1.Dia 80-800mm Length:2000-13000mm or as required

2.Technique:Forged

3.Delivery Time:45 days

Specifications of steel round bar:

1. Commodity: Round steel bar

3. Technical: Hot rolling

2. Length: Min. 5.8meter, according to requirement.

3. Diameter: 16mm-250mm

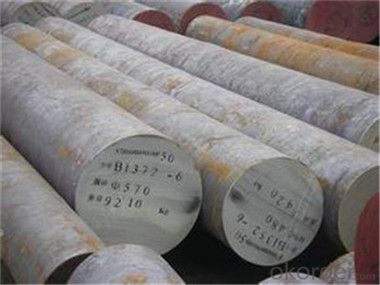

Images of steel round bar:

FAQ:

1. What is your main market?

We mainly export to Asia such as Japan,Korea,Thailand and North America and Middle East.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

4.Why do you choose to cooperate with us?

We have over10 years experience in this business so we are able to provide you the high quality products with the best price.

- Q: Is yuan steel round steel?

- The difference between steel and other steel: 1 is not the same, round shape light round, no pattern without ribs, other steel surface appearance is engraved or ribbed, cohesive force that cause steel and concrete, and the bond strength of steel and concrete in the other. 2 ingredients are different, round steel (grade a steel) belongs to ordinary low carbon steel, and other steel bars are mostly alloy steel.

- Q: How are steel round bars stored and transported?

- Steel round bars are typically stored and transported using a variety of methods to ensure their safety and ease of handling. When it comes to storage, steel round bars are often stored in warehouses or outdoor yards. In these facilities, the bars are usually stacked horizontally on racks or placed on steel stands to prevent any damages or deformations. It is important to keep the bars off the ground to avoid contact with moisture and potential rusting. To facilitate transportation, steel round bars are commonly bundled together using steel straps or chains. These bundles are designed to keep the bars tightly secured and prevent any movement during transit. Additionally, the bundles are often labeled with relevant information such as the type of steel, dimensions, and weight to ensure proper identification and handling. When it comes to transportation, steel round bars can be shipped using various modes such as trucks, trains, or ships. Trucks and trains are commonly used for shorter distances, while ships are preferred for longer hauls, especially for international shipments. Depending on the size and weight of the bars, they can be loaded onto flatbed trucks or placed in shipping containers for transportation. During transportation, it is crucial to avoid any potential impacts or mishandling that could cause damage to the bars. Proper securing and bracing techniques are employed to minimize any movement or shifting of the bars in transit. This can include using blocking and bracing materials to prevent the bars from rolling or sliding. In summary, steel round bars are stored in warehouses or outdoor yards and are often bundled together using steel straps or chains. They are transported using trucks, trains, or ships, ensuring proper securing and bracing to prevent damage. By following these storage and transportation practices, steel round bars can be delivered to their destinations safely and efficiently.

- Q: What is the difference between seamless and welded steel round bars?

- The manufacturing process and resulting characteristics distinguish seamless and welded steel round bars. Seamless bars undergo a process where a solid billet of steel is pierced to form a hollow tube. This tube is then elongated and further processed to achieve the desired dimensions and surface finish. The seamless manufacturing process guarantees a bar without any welds or joints along its length. Consequently, seamless steel round bars possess a uniform composition and structure throughout, ensuring exceptional strength and reliability. They are particularly favored for applications involving high pressure or high temperatures, as they display superior resistance to internal and external pressure. In contrast, welded steel round bars are produced by combining two or more steel pieces through welding techniques. This involves heating the ends of the steel pieces and fusing them together using various welding methods, such as arc welding, resistance welding, or fusion welding. The welding process introduces a weld seam along the length of the bar, which has the potential to impact its structural integrity and mechanical properties. Welded steel round bars may exhibit slightly lower strength and toughness compared to seamless bars due to the presence of the weld seam, which can create stress concentrations. Nonetheless, they are generally more cost-effective and readily available in a wide range of sizes and grades. To summarize, the primary distinction between seamless and welded steel round bars lies in their manufacturing process and resulting characteristics. Seamless bars are created through the piercing of a solid billet, ensuring a uniform composition and strength throughout, which makes them suitable for high-pressure and high-temperature applications. On the other hand, welded bars are formed by joining multiple steel pieces through welding, introducing a weld seam that may slightly affect their strength and toughness. Welded bars are often more cost-effective and available in various sizes and grades.

- Q: How are steel round bars used in the manufacturing of valves and fittings?

- Steel round bars are commonly used in the manufacturing of valves and fittings due to their strength, durability, and versatility. These round bars serve as the primary raw material for various components of valves and fittings. One crucial application of steel round bars in valve manufacturing is the production of valve stems. Valve stems are responsible for controlling the flow of fluids or gases through the valve. The round bars are machined and threaded to create the stem, which connects to the valve disc or plug. Steel round bars are chosen for this purpose because of their high tensile strength, which ensures the stem can withstand the pressure and torque required to operate the valve. In fittings manufacturing, steel round bars are commonly used to produce threaded connectors, nipples, and couplings. These components are essential for joining pipes or tubes together, allowing for fluid or gas transfer in various systems. Steel round bars are easily machinable, enabling manufacturers to create precise threads and shapes required for these fittings. Furthermore, steel round bars are also used to fabricate the body or housing of valves and fittings. The bars can be cut, forged, or machined into the desired shape, providing a sturdy and reliable structure for the valve or fitting. The use of steel in the body ensures the component's ability to withstand high pressures, temperature variations, and corrosive environments. Overall, steel round bars play a vital role in the manufacturing of valves and fittings. Their strength, durability, and machinability make them an excellent choice for creating critical components such as valve stems, threaded connectors, and the bodies of valves and fittings.

- Q: What are the cost considerations for steel round bars?

- The cost considerations for steel round bars typically include factors such as the grade and quality of steel used, the diameter and length of the bar, the quantity being purchased, and the current market conditions. Additionally, any additional processing, such as cutting or heat treatment, may also affect the overall cost.

- Q: What is the difference between a bright and a black steel round bar?

- The main difference between a bright and a black steel round bar lies in their appearance and surface finish. A bright steel round bar, also known as a bright drawn or turned bar, has a smooth and shiny surface. This is achieved through a process called cold drawing, where the steel bar is pulled through a die to remove any imperfections and create a uniform shape. The result is a highly polished and reflective surface that is visually appealing. On the other hand, a black steel round bar has a dark, rough, and non-reflective surface. This is because it does not undergo the same cold drawing process as a bright steel bar. The black surface is typically a result of the scale that forms on the steel during the manufacturing process, which is not removed. In terms of properties, both bright and black steel round bars are made of the same material, typically carbon steel. Therefore, their mechanical properties such as strength, hardness, and toughness are generally similar. However, the manufacturing process of the bright steel bar helps to improve its surface quality and dimensional accuracy compared to the black steel bar. Ultimately, the choice between a bright and a black steel round bar depends on the desired aesthetic appearance and the specific application requirements. Bright steel bars are commonly used in decorative applications, where a polished and visually appealing finish is desired. Black steel bars, on the other hand, are often used in structural applications, where the surface appearance is less important but strength and durability are crucial.

- Q: What are the different types of steel round bar surface finishes used in the marine industry?

- In the marine industry, there are several different types of steel round bar surface finishes that are commonly used. These finishes serve various purposes and have specific characteristics that make them suitable for specific applications. Here are some of the most common types of steel round bar surface finishes used in the marine industry: 1. Polished Finish: A polished finish is achieved by grinding the surface of the steel round bar to a smooth and reflective surface. This finish is commonly used in applications where aesthetics are important, as it provides a visually appealing and shiny appearance. Polished finishes are often used for decorative purposes on boat fittings, handrails, and other exposed areas. 2. Mill Finish: Mill finish refers to the surface condition of steel round bars as they come from the mill without any additional treatment. This finish is characterized by a rough and dull appearance, as it is not meant to be visually appealing. Mill finishes are typically used when a smooth or polished surface is not necessary, such as in structural applications or where the material will be painted or coated. 3. Shot Blasted Finish: Shot blasting is a surface treatment process that involves propelling small steel shots at high velocity onto the surface of the round bar. This process removes any surface impurities, scales, or rust, resulting in a clean and slightly textured finish. Shot blasted finishes are commonly used in marine applications where improved adhesion of coatings or paint is required, as the textured surface provides a better bonding surface. 4. Hot Rolled Finish: Hot rolled finish is achieved by subjecting the steel round bar to high temperatures during the manufacturing process, followed by rapid cooling. This process results in a scaly surface with a rough texture. Hot rolled finishes are suitable for marine applications where corrosion resistance is not a primary concern and where the material will be further processed or coated. 5. Galvanized Finish: Galvanizing is a process of applying a protective zinc coating to the surface of the steel round bar. This finish provides excellent corrosion resistance, making it ideal for marine applications where the material will be exposed to saltwater or harsh environmental conditions. Galvanized finishes are commonly used for boat trailers, marine hardware, and other components that require enhanced protection against corrosion. These are just a few of the different types of steel round bar surface finishes used in the marine industry. Each finish has its own unique properties and advantages, allowing for a wide range of applications in the maritime sector. The choice of finish depends on factors such as aesthetics, corrosion resistance, coating compatibility, and the specific requirements of the marine application.

- Q: Can steel round bars be used for making automotive chassis?

- Yes, steel round bars can be used for making automotive chassis. Steel round bars offer excellent strength, durability, and load-bearing capabilities, making them suitable for withstanding the weight and stress of an automotive chassis. Additionally, steel's flexibility and malleability allow for customization and shaping to meet specific design requirements.

- Q: Are steel round bars suitable for marine environments?

- Yes, steel round bars can be suitable for marine environments, but it depends on the specific type of steel used and the conditions of the marine environment. Stainless steel is often the preferred choice for marine applications due to its excellent corrosion resistance properties. Stainless steel contains chromium, which forms a protective layer on the surface of the steel, preventing corrosion and rusting. However, not all steel round bars are suitable for marine environments. Carbon steel, for example, is more susceptible to corrosion in marine environments, especially in the presence of saltwater. Carbon steel should be carefully protected with coatings or treatments to prevent corrosion. Additionally, the conditions of the marine environment also play a significant role in determining the suitability of steel round bars. Factors such as the salinity of the water, exposure to chemicals, temperature variations, and physical stress can affect the corrosion resistance of steel. In highly corrosive marine environments, it is advisable to use specialized marine-grade stainless steel or other corrosion-resistant alloys. Ultimately, it is crucial to select the appropriate grade of steel and consider additional protective measures, such as coatings or galvanization, to enhance the durability and longevity of steel round bars in marine environments.

- Q: What is the difference between a hot-rolled and a forged steel round bar?

- The main difference between a hot-rolled and a forged steel round bar lies in the manufacturing process and the resulting properties of the finished product. Hot-rolled steel round bars are produced by heating a billet or ingot of steel to a high temperature and then shaping it into the desired form using rollers. This process allows for a high volume of production and a wide range of sizes and shapes. As the steel is heated and shaped, it undergoes significant deformation and recrystallization, resulting in a uniform grain structure. Hot-rolled steel round bars have a rougher surface finish and can have varying levels of internal stress due to the cooling process. They are commonly used in applications where strength and cost-effectiveness are important, such as construction, manufacturing, and general fabrication. On the other hand, forged steel round bars are produced by applying extreme pressure to a heated billet or ingot of steel, typically using a hammer or a press. This process creates a much stronger and more durable product compared to hot-rolled steel. The intense pressure applied during forging aligns the steel's grain structure, resulting in improved mechanical properties such as increased strength, toughness, and resistance to fatigue and impact. Additionally, the forging process eliminates internal voids and porosity, making forged steel round bars more reliable and less prone to failure. Due to the high level of customization and precision involved in forging, these round bars are often used in critical applications that require superior strength and performance, such as aerospace, automotive, and oil and gas industries. In summary, the main differences between hot-rolled and forged steel round bars lie in their manufacturing processes and resulting properties. Hot-rolled steel offers cost-effectiveness and a wide range of sizes and shapes, while forged steel provides superior strength, durability, and reliability. The choice between the two depends on the specific application and the desired performance characteristics.

Send your message to us

SCM440 Forged or Hot Rolled Sae 4140 Alloy Steel Round Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 123 m.t.

- Supply Capability:

- 2005544 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords