Scdot Polyester Geotextile Fabric for Road Construction in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

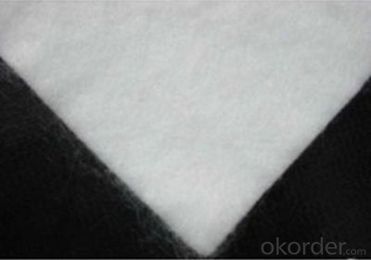

Non woven geotextile can be made of polypropylene (PP), or polyester (PET), Polyvinyl or synthetic fiber on needle punch machine. The mass is available from 100gsm/m² to 1000gsm/m² and the width available from 1.0m-6.0m, monolayer or multilayer (reinforcement geotextiles), long fiber or short fiber.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: The properties of woven geotextiles

- Product features: 1, with a reinforcement function: to stabilize the project in the course of prolonged use of the transfer occurred, and can be the role of the soil in the local stress transmission or assigned to a larger area. 2, with the role of separation: woven geotextile with different geotechnical structure to form a stable interface, in accordance with the requirements to play their own characteristics and the overall role. 3, the role of drainage filter: allow moisture to block the loss of sand particles, in the drainage of geotextiles on the poor water in the soil can play the water along the geotextile quickly discharged the purpose. 4, the geotextile and geomembrane used in two different pressures between the material can play a role in tension diaphragm. 5, with a block function: the geotextile placed in the flow of liquid with suspended particles in the channel to organize fine mud particles, and allow the liquid through the function. 6, play the role of cushion mat: the geotextile placed on the slope can prevent the soil particles due to the erosion of rain and the loss or planting turf.

- Q: How do geotextiles help with soil confinement in erosion control bags?

- Geotextiles help with soil confinement in erosion control bags by providing a strong and permeable barrier that prevents soil particles from escaping. They act as a stabilizing agent, keeping the soil intact within the bags while still allowing water to flow through, reducing erosion and promoting vegetation growth.

- Q: How do geotextiles help with drainage?

- Geotextiles help with drainage by allowing water to pass through their porous structure while preventing soil particles from clogging the drainage system. This enables efficient water flow, reduces soil erosion, and helps maintain the stability and longevity of the drainage infrastructure.

- Q: Are geotextiles suitable for use in geocell mattress systems?

- Yes, geotextiles are suitable for use in geocell mattress systems. Geotextiles have excellent filtration and separation properties, which help in preventing soil erosion and maintaining stability within the geocell system. They also provide reinforcement and allow for the proper drainage of water, making them an ideal choice for use in geocell mattress systems.

- Q: What are the key considerations for geotextile installation in corrosive environments?

- The key considerations for geotextile installation in corrosive environments include selecting a geotextile material that is resistant to corrosion, ensuring proper anchoring and fastening methods to prevent movement or damage, conducting regular inspections and maintenance to identify any signs of corrosion, and implementing appropriate protective measures such as using a geotextile with a higher corrosion resistance rating or adding a barrier layer to minimize exposure to corrosive agents.

- Q: Where can the general use of geotextile water can be bought

- Lingxian geotextile manufacturers, welcome to visit

- Q: Can geotextiles be used in coastal protection systems?

- Yes, geotextiles can be used in coastal protection systems. They are commonly used to stabilize and reinforce coastal areas by acting as a barrier against erosion, helping to control sediment movement, and providing structural support. Geotextiles offer benefits such as improved drainage, increased soil stability, and reduced wave energy, making them an effective solution for coastal protection projects.

- Q: What is geotextile? Geotextile is what

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance characteristics. Geotextile is one of the geosynthetics, the application of geosynthetics originated in the fifties of the twentieth century, the domestic geotextile is one of the national eight five plan, China promulgated in 1998, "geosynthetics staple fiber Acupuncture non-woven geotextile "(GB / T-1998) standard, the current geotextile has been widely used in many areas.

- Q: Can geotextiles be used in road shoulder stabilization?

- Yes, geotextiles can be used in road shoulder stabilization. Geotextiles are commonly used in civil engineering projects to reinforce and stabilize different areas, including road shoulders. They help to prevent erosion, improve soil stability, and provide a solid foundation for road construction.

- Q: How do geotextiles aid in the reduction of lateral spreading?

- Geotextiles aid in the reduction of lateral spreading by providing reinforcement and stability to soil structures. These textiles are designed to have high tensile strength and are placed horizontally within the soil to act as a barrier against the lateral movement of soil particles. This helps to distribute stress and prevent the soil from shifting laterally, thereby reducing the potential for slope failure or landslides.

Send your message to us

Scdot Polyester Geotextile Fabric for Road Construction in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords