High-Quality Aluminum Transition Strips for Flooring - DC or CC Material Aluminum Sheet for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Aluminum have been the primary material of choice for structural components of aircraft since about 1930.

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Oil and petrochemical industries (i.e. tools for use in non-sparking environments

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,Natural occurrence

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

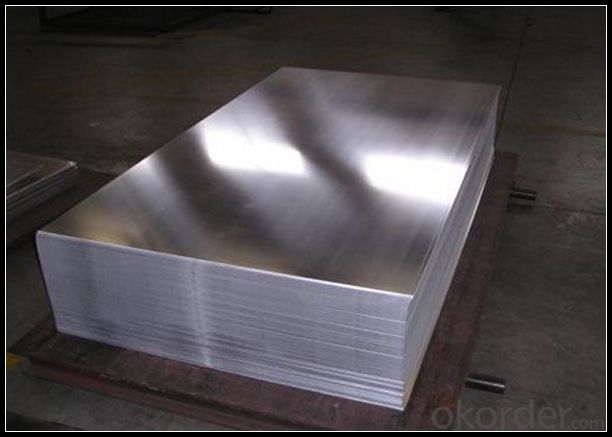

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What is the best capacitance for an aluminum ribbon tweeter?

- You can ask your friends on the Internet to inquire about them, they will be more sincere, eager to find the answer for you, and even direct search related sites

- Q: What specific tools or equipment are necessary to install aluminum strips?

- <p>To install aluminum strips, you generally need a few basic tools. A measuring tape is essential for accurate placement. A utility knife or a metal cutting tool is necessary for cutting the strips to the correct length. A level is crucial to ensure the strips are straight. A rubber mallet or a hammer can be used to secure the strips in place. Adhesive, such as construction adhesive or double-sided tape, is often required to attach the strips. Safety equipment like gloves and safety goggles should be worn to protect against sharp edges and debris.</p>

- Q: This question asks for an overview of the various types of aluminum strips that are available in the market.

- <p>Aluminum strips are available in various types based on their thickness, width, alloy composition, and surface finish. Common types include: 1) Plain aluminum strips, which are general-purpose and used in packaging and construction. 2) Embossed aluminum strips, used for decorative purposes or to enhance grip. 3) Anodized aluminum strips, which offer improved corrosion resistance and are used in automotive and aerospace applications. 4) Heat-treated aluminum strips, which have enhanced strength and are used in structural components. 5) Coated aluminum strips, which have a protective or decorative layer applied, used in food packaging and electronics. 6) Foil strips, which are very thin and used in food packaging, pharmaceuticals, and thermal insulation. Each type has specific applications and properties that make it suitable for particular industries and uses.</p>

- Q: Is it possible to use aluminum strips for creating jewelry or crafts?

- <p>Yes, you can use aluminum strips to make jewelry or crafts. Aluminum is a lightweight, durable, and affordable metal that is easy to shape and manipulate. It can be cut, bent, and twisted into various designs. Due to its resistance to corrosion, aluminum is also a good choice for items that will be exposed to moisture or wear. However, it's important to note that while it's versatile, aluminum is softer than other metals, so it may require additional support or reinforcement in certain applications.</p>

- Q: What specific tools are required for the installation of aluminum strips on a roof or wall?

- <p>To install aluminum strips on a roof or wall, you generally need a few special tools. These include a measuring tape for precise measurements, a level to ensure the strips are straight, a drill for making holes, and screws or nails for securing the strips. A utility knife may be required for cutting the strips to size, and a pry bar can help with positioning. Safety equipment like gloves and goggles is also essential to protect against sharp edges and debris.</p>

- Q: What are the potential dangers or issues that could arise from using adhesive to attach aluminum strips?

- <p>Using adhesive to install aluminum strips can involve certain risks. These include the possibility of the adhesive failing over time, leading to the strips becoming loose or falling off. There's also a risk of the adhesive damaging the surface it's applied to, especially if it's not removed carefully or if it's a sensitive material. Additionally, improper installation can lead to an uneven or unattractive finish. It's important to use a high-quality adhesive suitable for the material and follow the manufacturer's instructions to minimize these risks.</p>

- Q: Is it possible to apply paint to aluminum strips once they have been installed?

- <p>Yes, aluminum strips can be painted after installation. However, it is essential to prepare the surface properly. This includes cleaning the aluminum to remove any dirt or grease, then lightly sanding it to create a better surface for the paint to adhere to. It is also recommended to use a primer specifically designed for metal surfaces to enhance the paint's durability and adhesion. After priming, the aluminum strips can be painted with a suitable paint, such as a high-quality acrylic or enamel paint, following the manufacturer's instructions for application and drying times.</p>

- Q: How can the aluminium band be welded to the steel shell?

- If it is more than 0.5 mm by resistance heating welding, welding materials need to use the 303B welding wire Odin wei.Welding tools: carbon block welding, welding with two electrodes.

- Q: What are the distinctions between pure aluminum and its alloys?

- <p>Aluminum and aluminum alloys have distinct properties. Pure aluminum is a soft, lightweight metal with good thermal and electrical conductivity. It is highly reflective and resistant to corrosion. Aluminum alloys, on the other hand, are made by combining aluminum with other elements such as copper, magnesium, or silicon to enhance its strength, durability, and resistance to heat and wear. These alloys are stronger and more versatile than pure aluminum, making them suitable for a wide range of applications, from aerospace to construction.</p>

- Q: Is it possible to use aluminum foil as a material for roofing purposes?

- <p>While aluminum foil itself is not a suitable roofing material due to its lack of durability and structural strength, it can be used as a temporary solution in emergency situations or for small repairs. Aluminum foil is not designed to withstand the elements over time, nor does it provide the necessary insulation or protection against water and wind that a proper roofing material should. For long-term roofing solutions, it's best to use materials specifically designed for roofing, such as asphalt shingles, metal sheets, or tiles, which offer greater durability and weather resistance.</p>

Send your message to us

High-Quality Aluminum Transition Strips for Flooring - DC or CC Material Aluminum Sheet for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords