Roller for Steel Rolling Mill Forged Mill Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Roller for Steel Rolling Mill Forged Mill Roll

Products Description

Centrifugally cast compound steel back -up rolls have a shell of cast steel with alloying elements such as Ni,Cr,Mo.After heat-treatment the roll shell get a fine temper structure, which exhibits good strength and ductility combined with high fatigue properties. When used, the roll shows a high wear and spalling resistance all the time.

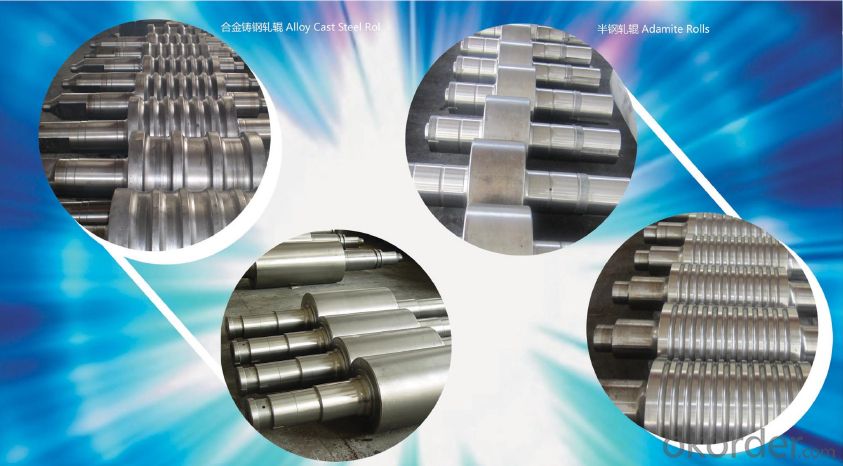

Products Pictures

Chemical Composition:

Classification | C | Si | Mn | P | S | Ni | Cr | Mo |

CrMo semi-chilled nodular cast iron rolls | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 0.20-0.60 | 0.20-0.60 | |

CrMo indefinite chilled nodular cast iron rolls | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 0.20-0.60 | 0.20-0.60 | |

NiCrMo indefinite chilled nodular castiron rolls(Ⅰ) | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 0.50-1.00 | 0.20-0.60 | 0.20-0.80 |

NiCrMo indefinite chilled nodular castiron rolls(Ⅱ) | 2.90-3.60 | 0.80-2.50 | 0.40-1.20 | ≤0.25 | ≤0.03 | 1.01-2.00 | 0.30-1.20 | 0.20-0.80 |

Nodular pearlitic rolls(SGPI) | 2.90-3.60 | 1.40-2.20 | 0.40-1.00 | ≤0.15 | ≤0.03 | 1.50-2.00 | 0.10-0.60 | 0.20-0.80 |

Nodular pearlitic rolls(SGPⅡ) | 2.90-3.60 | 1.20-2.00 | 0.40-1.00 | ≤0.15 | ≤0.03 | 2.01-2.50 | 0.20-1.00 | 0.20-0.80 |

Nodular pearlitic rolls(SGP Ⅲ) | 2.90-3.60 | 1.00-2.00 | 0.40-1.00 | ≤0.15 | ≤0.03 | 2.51-3.00 | 0.20-1.00 | 0.20-0.80 |

Centrifugally acicular nodular cast iron rolls(SGAⅠ) | 2.90-3.60 | 1.20-2.20 | 0.20-0.80 | ≤0.10 | ≤0.03 | 3.01-3.50 | 0.20-1.00 | 0.50-1.00 |

Centrifugally acicular nodular cast iron rolls(SGAⅡ) | 2.90-3.60 | 1.00-2.00 | 0.20-0.80 | ≤0.10 | ≤0.03 | 3.51-4.50 | 0.30-1.50 | 0.50-1.00 |

NiMo nodular cast iron roll( Ⅰ) | 2.90-3.50 | 1.50-2.40 | 0.40-0.80 | ≤0.05 | ≤0.03 | 1.00-2.50 | 0.10-0.50 | 0.40-0.80 |

NiMo nodular cast iron roll( Ⅱ) | 2.90-3.50 | 1.20-2.40 | 0.40-0.80 | ≤0.10 | ≤0.03 | 2.51-3.50 | 0.10-0.50 | 0.40-1.00 |

Physical Performance:

Products | Barrel Hardness (HSD) | Neck Hardness (HSD) | Tensile Strength (Mpa) |

CrMo semi-chilled nodular cast iron rolls | 40-55 | 35-55 | >300 |

CrMo indefinite chilled nodular cast iron rolls | 55-70 | 35-55 | >300 |

NiCrMo indefinite chilled nodular cast iron rolls(Ⅰ) | 55-70 | 35-55 | >300 |

NiCrMo indefinite chilled nodular cast iron rolls (Ⅱ) | 60-70 | 35-55 | >300 |

Nodular pearlitic rolls (SGPI) | 60-70 | 35-55 | >450 |

Nodular pearlitic rolls (SGPⅡ) | 55-65 | 35-55 | >450 |

Nodular pearlitic rolls (SGP Ⅲ) | 62-72 | 35-55 | >450 |

Centrifugally acicular nodular cast iron rolls(SGAⅠ) | 55-78 | 32-45 | >350 |

Centrifugally acicular nodular cast iron rolls(SGAⅡ) | 55-78 | 32-45 | >350 |

NiMo nodular cast iron roll( Ⅰ) | 42-52 | 32-43 | >300 |

NiMo nodular cast iron roll( Ⅱ) | 42-52 | 32-43 | >300 |

Quotation Elements

| ITEM | QUOTATION ELEMENTS |

1 | What kind of products the factory produce? Hot Rolled Steel Coil? Cold Rolled Steel Coil? Wire Rod? Rebar? |

2 | Production Process of Roll --Cast or Forged |

3 | Grade of Roll |

4 | Chemical Composition of Roll |

5 | Physical Property of Roll: Hardness/Tensile Strength/Elogation/Bening Strength |

6 | Drawing of Roll |

7 | Quantity |

8 | Delivery time |

Quality Control and Package

Products Display

- Q: What kinds of carbide cutting tools are used in the 16 and 20 manganese grinding of the lathe?

- This material I have processed, it is equivalent to Q235 carbide tools, wear-resistant coarse cars, YW, fine car YT15YG: for cast ironYT: suitable for processing steel partsYW: the material performance of the tool is between YG and YTYN: it is a cermet blade suitable for machining superhard materials.Diamond: cutting tools are suitable for machining superhard materials, but they can not be processed steel or ironIn order to be compatible with them.CBN: Machining superhard materials.

- Q: What is the difference between hard alloy and steel

- Cobalt (Co) is used in bonding in the alloy, is in the process of sintering, it can make the tungsten carbide (WC) powder and tightly surrounded Bonded together, after cooling, became hard alloy. (equivalent to the cement content). Usually: 3%--30% tungsten carbide (WC) is the main component of some metal properties of the hard alloy or cermet, the total composition of 70%---97% (weight ratio) is widely used in wear-resistant, high temperature resistance, resistance corrosion, bad working environment of the parts or tool, cutter tools.

- Q: Hello, what's your company? What do you do with carbide? Thank you in advance

- Pro, what do you mean by that question? We are the hard alloy recycling companies, focus on hard alloy recovery, Qingdao cemented carbide business network, with the recovery of hard alloy scrap, hard alloy die, tungsten steel scrap recycling

- Q: What cemented carbide does 2gr13 use?

- 2Cr13 martensitic stainless steel can be processed by hard alloy YW2, carbide YW2 suitable for heat-resistant steel, high manganese steel, stainless steel and advanced alloy steel and other special difficult to processing steel finishing, semi finishing.

- Q: What are the types and specifications of carbide cutters?

- The main components are tungsten carbide, titanium carbide (TiC) and cobaltThe grade by "YT" ("hard ti" Pinyin prefix) and the average content of titanium carbide.For example, YT15 is a tungsten titanium cobalt carbide that represents an average WTi = 15% and the remainder is tungsten carbide and cobalt content

- Q: What are the advantages of carbide V-CUT knives and diamond V-CUT knives?

- Hard alloy cutter V-CUT V-CUT also known as tungsten steel knife, V-CUT knife is a highly cost-effective high quality, the overall use of hard alloy is refined, the hard alloy is a kind of tungsten cobalt powder by formula + mixture by pressing sintering of cemented carbide wafer using high quality carbide hard alloy, and then by the advanced precision grinding machining the tool made.Diamond cutting tools are relatively hard and have a hardness of 8000HV.

- Q: Make cutting dosage

- In general, T alloys are mainly used to process ferrous metals, because T alloys contain Ti elements (solid solutions), which can effectively reduce the flank wear and wear resistance of the crater, thereby increasing the tool life;G alloy is mainly used to process non-ferrous metals and non metals, because the G alloy can achieve more sharp tool tip and reduce the cutting force effectively.

- Q: What alloy tool can be used as hard alloy?

- KYOCERA's KBN cutters and diamond cutters pay attention to cutting in and out of each piece of 318

- Q: K carbide carbide cutting tools, mainly used for turning what materials?

- Suitable for processing stainless steel, non-ferrous metals, non-metallic materials, cast iron and so on

- Q: Printing requirements for cemented carbide

- Since 80s the advent of nano cemented carbide, and gradually formed a new sintering method, such as microwave sintering, field assisted sintering (such as spark plasma sintering and plasma activated sintering), two stage sintering, selective laser sintering etc..Vacuum sintering (Vacuum Sintering) is one of the more widely used methods for cemented carbide sintering, which began in the 30s of last century,Great progress has been made in the past thirty years. Vacuum sintering is the process of sintering and pressing in a negative pressure gas medium. Vacuum sintering can improve the purity of furnace gas and the negative pressure can improve wettability of bonded hard phase. Vacuum sintering has the following advantages: sintering in vacuum condition, hinder greatly reduces the adsorption of gas on the surface of powder and closed pore gas on the densification of the powder, is favorable to the diffusion process, which is conducive to the densification; better able to exclude Si, Mg and Ca in the sintered body trace of oxide impurities thus, to improve the purity of hard alloy; improve the wettability of liquid phase sintering, is conducive to tissue shrinkage and improve the alloy.

Send your message to us

Roller for Steel Rolling Mill Forged Mill Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords