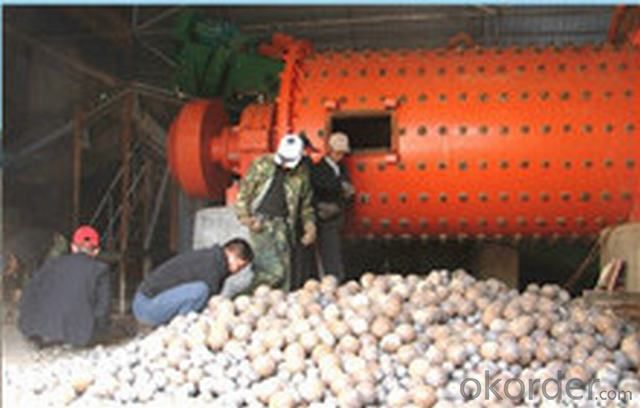

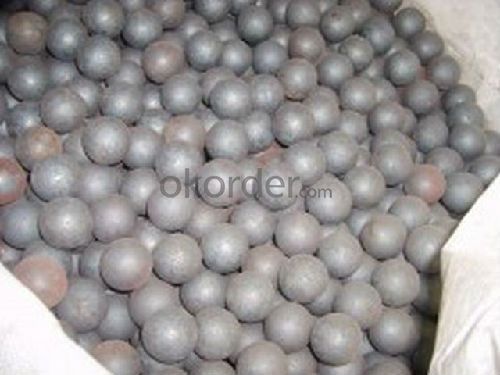

High Hardness Forged and Casting Grinding Mill Steel Ball For Ball Mill

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our grinding ball are widely used for powder preparation and extra-fine deep processing in sectors, such as cement building materials, metal mining, coal paste thermal power plants, chemical engineering, ceramic coating, light industrial paper making and magnetic materials. The cast grinding ball's hardness is high; wearing cost is low; the toughness is very good. So the breakage is few. The surface hardness of ball will be raised further in using the course, and the wear resistance would gather hard to raise mill machine production capacity and raise cement's ratio surface area and reclaim ratio of the extractive mine.

Specification of High Hardness Forged and Casting Grinding Mill Steel Ball For Ball Mill

No. | Diameter (mm) | Weight of each (kg) | Pcs/ton |

1 | Ø20 | 0.0322 | 31056 |

2 | Ø25 | 0.063 | 15873 |

3 | Ø30 | 0.11 | 9091 |

4 | Ø40 | 0.257 | 3891 |

5 | Ø50 | 0.50 | 2000 |

6 | Ø60 | 0.867 | 1153 |

7 | Ø70 | 1.37 | 729 |

8 | Ø80 | 2.05 | 487 |

9 | Ø90 | 2.90 | 345 |

10 | Ø100 | 4.00 | 250 |

11 | Ø110 | 5.30 | 188 |

12 | Ø120 | 6.80 | 147 |

13 | Ø125 | 7.75 | 129 |

14 | Ø130 | 8.74 | 114 |

The Product Description of High Hardness Forged and Casting Grinding Mill Steel Ball For Ball Mill

Model | Mechanical properties | Microstructure | |

HRC | Times of falling (3.5m) | ||

Low Chromium | ≥45 | 8000 | P+C |

Medium Chromium | ≥50 | 8000 | P+C |

High Chromium | ≥56 | 8000 | M+C |

Chemical Composition of High Hardness Forged and Casting Grinding Mill Steel Ball For Ball Mill

Model | Chemical Composition | |||||

C | Si | Mn | Cr | P | S | |

Low Chromium | 2.3-3.4 | ≤1.5 | 0.5-1.5 | 1.0-2.0 | ≤0.1 | ≤0.1 |

Medium Chromium | 2.2-2.8 | 0.5-1.0 | 0.5-0.8 | 10.0-12.0 | ≤0.1 | ≤0.1 |

High Chromium | 2.4-3.2 | 0.5-0.8 | 0.5-0.8 | 16.0-18.0 | ≤0.1 | ≤0.1 |

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- Casting, do not need to provide a rough casting foundry drawings, according to your chart will put foot margin in the processing needs of the surface, the rest of the size can be found according to the mechanical design manual and manual casting. General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Use the vibrator to polish the material: the high aluminum porcelain 4cm (with a polishing agent that has an automatic mending function), you go find this polish,

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- For the nodular cast iron, the hardness, strength and wear resistance are improved, such as used in the manufacture of automobile, tractor, diesel engine crankshaft, connecting rod and other important parts. A normalizing and hypereutectoid ball annealing before, can eliminate the mesh two cementite spheroidizing annealing, to ensure that all spheres of cementite. Annealing is a metal heat treatment process, which means the metal is slowly heated to a certain temperature, sufficient for a long time, and then cooled at an appropriate speed. The purpose is to reduce hardness, improve machinability, eliminate residual stress, stabilize size, reduce deformation and crack tendency, refine grain, adjust microstructure and eliminate tissue defects. Its purpose: (1) reduce hardness and improve machinability; (2) eliminate residual stress, stabilize size, reduce deformation and crack tendency; (3) refine grain, adjust microstructure and eliminate tissue defects. In production, annealing process is widely used.

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: The casting sand is going on

- 3, prevention measures(1) to improve the strength of sand mold (core), especially surface strength, high temperature strength, refractoriness, compact, better coating, good core coating and parting surface coating.(2) mould and box can prevent damage;(3) the core should have clearance.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q: What should I pay attention to when designing a casting structure?

- (2) in the prevention of metal mold casting misrun and cold partition should pay attention to the following problems: the structure of A casting thickness should be appropriate not too thin, especially when casting size when not too thin; the B should avoid a big level, because it makes the liquid metal in the casting. Rise slowly, and the air contact surface, easy oxidation, and because the metal type liquid metal heat quickly, quickly lose liquidity, easy to cause misrun and cold lap, slag and other defects; C casting shape should be streamlined to avoid sharp corners and has sharp change connection structure in order to facilitate the flow of liquid metal. 2 in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

- Q: Where is the precision casting factory?

- Everywhere is. Look what you want to do

- Q: What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q: The difference between sheet metal and casting parts

- Commonly used in machine tools casting material is gray cast iron, casting bearing alloys can also be.

1. Manufacturer Overview

| Location | Anshan City, Liaoning Province,China |

| Year Established | 2002 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Domestic Market; South America; Eastern Asia; South Asia; Mid East |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port;Dalian Port;Tianjin Port;Yingkou Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6 - 10 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | 24,400 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | grinding ball,grinding media,casting ball,casting grinding ball |

| Product Price Range | Average |

Send your message to us

High Hardness Forged and Casting Grinding Mill Steel Ball For Ball Mill

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords