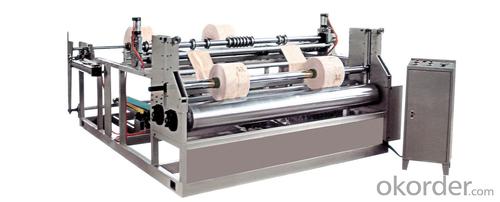

Roll to Roll Paper Slitting Rewinding Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Roll to Roll Paper Slitting Rewinding Machine Function

1. Double blades (upper blades and down blades) slitting. Cutting edges are more smooth and neat.

2. Adopt shaftless material loading device which can bear 2000kgs weight.

3. Pneumatic loading and unloading system; material paper roll loading and finished rolls unloading to be automatically.

Roll to Roll Paper Slitting Rewinding Machine Technical Parameters

Technical Parameter | Control System | ||

Material Paper | 40-600gsm | Main Motor | 15kw Wannan |

Unwind Width | 600-1600mm | Inverter | 18.5KW Delta (Taiwan) |

Unwind Diameter | 1200mm (standard) | Lifting Motor | 1.1kw*2 pcs Wannan |

Rewind Diamter | 1200mm (standard) | Clamping Motor | 1.5kw *2 pcs Wannan |

Minimum Slitting Width | 35mm | Execute Components | CHNT |

Working Speed | 0-250 meters/min | Signal Components | Hugong |

Speed regulation | By Inverter | Pneumatic Components | Jingwei |

Material Loading Device | Shaftless Device | Electric Components | CHNT |

Loading Type | Automatically by Pneumatic (hydraulic can be customized) | Bearing | Haerbin |

Rewinding Type | Air Inflation Shaft | Configuration | |

Unloading Type | Automatically by Pneumatic | Material Paper Fixing Cone | 2 Pieces (76mm ID) |

Power Supply | 380V/3Phase/50Hz (can be customized) | Lifting Air Cylinder | 2 Pieces |

Discharging Air Cylinder | 2 Pieces | ||

Size | Material Shafts Braking Device | 2 Sets | |

Mainframe (two parts) | 3000*1700*1100mm (Unwinding side) | ||

Blades | 20 Sets (standard) | ||

3300*1200*1200mm (Rewinding side) | Operating Box | 1 Set | |

Curved Roll | Have | ||

Weight | 3200kgs | Meter Counter | Optional |

Enclosed Spare Parts | Automatic Correcting Unit | Optional | |

Useful Tool | 1 Set | ||

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine machine standard price of about 38000, excluding tax, tableware packaging machine is designed for tableware (e.g., chopsticks, bowls, dishes and so on) a modern packaging machinery packaging, this machine is mainly composed of conveyor, packaging machine, output machine, shrink machine, composed of four parts.

- Q: What is the delay time of the packer's cross sealing?

- You can debug it yourself, set up a parameter, such as a delay of 1 second or a few seconds, look at the action of sealing, you know what time it is.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- Take the food packaging machine for example, if only from the hardware, then you can ask when you buy the degree of automation, semi-automatic or fully automatic, the use of steel ah,

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resinUre-aformaldehyde resinsUrea formaldehyde polymer. Also called urea formaldehyde resin. The cross-linking English abbreviation UF. molding, the product is insoluble and infusible thermosetting resin, urea formaldehyde resin cured phenolic resin than the color of light, translucent resistance, weak acid and weak alkali, good insulation properties, excellent wear resistance, low price but, in case of strong acid and strong alkali decomposition, weather resistance is poor. The name Beetle. urea and 37% formaldehyde aqueous solution can be obtained by the polycondensation of linear urea formaldehyde oligomer in catalytic acid or alkali industry, with alkali as catalyst, reaction temperature of about 95, the molar ratio of formaldehyde to urea as 1.2.0, to ensure that the resin curing reaction. The first step to generate and dimethylol urea, then hydroxymethyl amino and soluble resin by further condensation, if by acid catalysis, easy to cause the product to be stored to gel. In neutral condition. The linear UF resin for ammonium chloride Curing agent can be cured at room temperature. The molding powder at 130 to 160 DEG C heat curing accelerators such as zinc sulfate, trimethyl phosphate, two oxalic acid ethyl ester can accelerate the curing process. The urea formaldehyde resin is mainly used in the manufacture of molded plastic manufacturing, daily life products and appliance parts, also can be used as adhesive, paper and fabric sheet the pulp, plywood, decorative board and so on. Because of its light color and easy coloring, products often colorful and magnificent.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- Because the packaging machinery is divided into many types, so many species also have different models, basically need to use packaging products requires packaging machinery, if not to fine some, it is necessary to sort of packaging machinery, slowly down. Packaging machinery is not required to use a certain scale, packaging machinery as well as automatic, semi-automatic, manual distinction. Most small workshops, or small factories, are semi automated or manual. If some of the larger factories will use automatic, or even a whole production line to complete automated packaging.

- Q: What are the structures of the packaging machinery?

- Is a company engaged in outsourcing clients, packaging, processing, packaging equipment, leasing, services, sales in one of the specialized companiesSales of second-hand packing equipment according to the customer's product features and requirements. Reduce customer purchasing costsAccording to the customer's product characteristics and requirements. Select the best packaging equipment for customers, reduce customer purchasing costsPackaging equipment spare parts sales and maintenance services

- Q: What's the fastest packing machine?

- Depending on the characteristics of your material, the speed is adjustable!

- Q: What is a packaging machine?

- Meet the needs of mass production and meet the requirements of clean sanitationUsually some non-standard equipment, the common is pneumatic and simple combination of electrical components, to meet the requirements of factory automation

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard applies to the use of heat sealing glass paper, BOPP, PVC film and other packaging materials, packaging machine for carton box type items or single package or bag or several stacked and wrapped sealing, widely used in food, medicine, tobacco, cosmetics, stationery, audiovisual products etc.. This standard needs to be purchased.

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

Roll to Roll Paper Slitting Rewinding Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords