FULLY-AUTO L BAR SEALER and SHRINK TUNNEL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

SF-400LA is a fully automatic unmanned operation “L” type sealing machine which is widely used in mass production packaging line with high efficiency. Automatic film feeding punching device, manually adjustable film-guide system and feeding conveyor platform make the machine suitable for different width and height items. SF-400LAC has closely connecting function which specially designed for small items

Sealing knife uses the aluminum knife with DuPont Teflon which is anti-stick coating & anti-high temperature. So the sealing will not have cracking, coking and smoking with zero pollution;

Equipped with imported photoelectric of horizontal and vertical detection for choice to easily finish the sealing of thin and small items;

Automatically-feeding: the length can be auto adjusted by the sensor and time relay. Matched the reduction motor makes the waste film automatically rolling;

When the packaging size changes, the adjustment is very simple by rotating the hand wheel without changing molds and bag makers;

Different size products can also be packaged combinations to achieve the promotional effect;

Using original Autonics digital temperature controller which built-in PID function. Sealing blade temperature is extremely sensitive and accurate and we can be arbitrarily set. Do not worry about hurting the product for imprecise temperature. The sealing blade itself is also equipped with automatic protection function which effectively prevent from accidental cutting;

The machine is equipped with organic glass shield with automatic alarm function which greatly improves safety;

The entire machine realizes unmanned operation with the production line connecting;

l Film up-down synchronization mechanism specially designed to correct the deviation film;

l I can be added easily tear functions according to customer requirements;

l Applies to software, food, cosmetics, printing, pharmaceutical, flooring, ceramic, beverages, hardware and other industries’ large quantities of shrink wrap

Parameters

Model | SF-400LA | SF-400LAC | SF-4525 |

Power | 2.2kw | 2.3kw | 9kw |

Power Supply | AC 220V 1/3PH 50/60Hz | AC 220V 1/3PH 50/60Hz | AC 380/220V 50/60Hz 1/3PH |

Max. Packing Size L×W×H | L+H≤530mm W+H≤430mm H≤135mm | L+H≤530mm W+H≤430mm H≤135mm | 1000×300×200mm |

Max. Sealing Size L×W×H | L550×W450mm | L550×W450mm | / |

Packing Speed | 15m/min. | 15m/min. | 0~20m/min. |

External Air Source | 6-8kg/cm2 | 6-8kg/cm2 | / |

Shrink Film | POF | POF | POF |

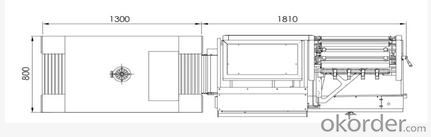

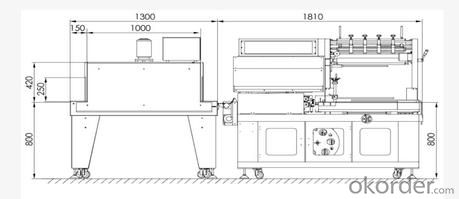

Machine Size L×W×H | 1810×880×1600mm | 1810×880×1600mm | 1300×800×1520mm |

Packaging Size L×W×H | 1860×930×1750mm | 1860×930×1750mm | 1350×850×1670mm |

G./N. Weight | 330/280kgs | 380/300kgs | 320/280kgs |

- Q: What is the general packing cost of beer beverage packaging?

- In addition, according to the product's own conditions to set, the packaging machine prices are generally in the range of 3-5 yuan

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q: What are the main plastic forming processes?

- 3. cold pressing molding. Cold pressing molding is also called cold pressing sintering molding. The difference between the cold press molding and the ordinary compression molding is that the material is pressurized and molded at room temperature. The mold after release can be heated or cured by chemical action. This method is used in the forming of polytetrafluoroethylene and some high temperature resistant plastics (such as polyimide, etc.). The general process is three steps of billet sintering cooling.4. transfer molding. Transfer molding is a molding process for thermosetting plastics. When molding, the mold is heated and softened in the heating chamber and then pressed into the mold cavity where it has been heated. According to the different types of transfer molding equipment form: trap type; the tank; the piston.The requirement of plastic molding for transfer molding is that the plastic should have a greater fluidity before reaching the curing temperature, and the curing rate must be faster at the curing temperature. Phenol, melamine, formaldehyde and epoxy resins can meet this requirement.Transfer molding has the following advantages: less waste edge products, can reduce the processing quantity; second molding with fine or brittle insert and perforation of the products, and can keep the insert and the hole position is correct; the product performance is uniform, accurate size, high quality; the mould wear small. The disadvantage is that the manufacturing cost is high compression mold die; the plastic loss; the fiber reinforced plastics for fiber orientation and anisotropy; and around the insert around the plastic, sometimes due to melting is not strong and make the products according to the strength reduction.

- Q: What kind of reducer is commonly used in packaging machinery?

- Generally speaking, gear reducer, planetary gear reducer, and the most common one, these equipment power is relatively small, and some need to take the brakes of the motor reducer

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine machine standard price of about 38000, excluding tax, tableware packaging machine is designed for tableware (e.g., chopsticks, bowls, dishes and so on) a modern packaging machinery packaging, this machine is mainly composed of conveyor, packaging machine, output machine, shrink machine, composed of four parts.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- If these are good, and then talk about the price, always a penny goods, this side, quick packaging machine is not bad,

- Q: What is the working principle of the pillow packing machine?

- In fact, the special machine is often better than the packaging of the compatible machine. A packing machine should be packed in no more than 3-5 varieties. What's more, the products with the larger size and the difference in size should be packed separately as much as possible.

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Graphic symbols for packaging and storageGB/T 5009.60. Analytical method for hygienic standard of polyethylene, polystyrene and polypropylene moldings for food packaging

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Mechanical sales are nothing more than two points: first, equipment aging, need to update; two, equipment efficiency is low, need to improve. You don't know anything about the customer. Come up and sell the product. If you are a customer, I don't think you have the patience to listen

Send your message to us

FULLY-AUTO L BAR SEALER and SHRINK TUNNEL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords