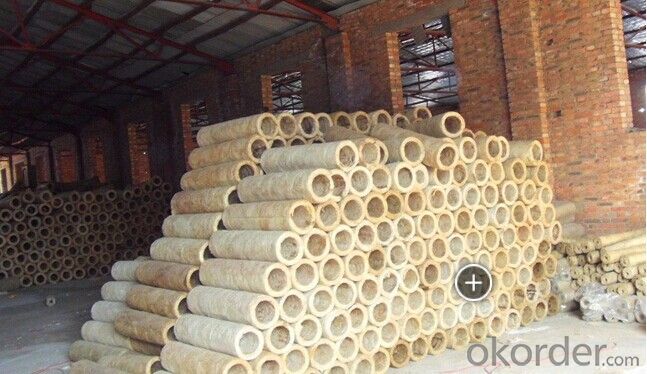

Rock Wool Roll Yellow Color Rock Wool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

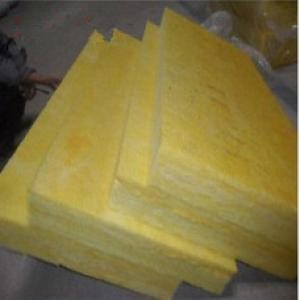

High quality and good price rock wool board

1)Fireproof Grade:A1

2)Heat conduct coefficient:0.030-0.044

3)Fiber Dia:4-7

The rock wool product is made from basalt as main ingredient which is made into the fiber in high speed centrifugal machine after melting at temperature about 1450°C. Adding the proportional resin, it can be processed into rock wool board, blanket and pipe according to the customer requirement.

Application:

1. Used for fire protection, thermal insulation in public, commercial and residential buildings.

2. Used for sound absorption in roofing, external wall, partition wall and floating floor.

3. Low density rock wool board suitable for roof and wall in thecture build

Reflective insulation material consists of one or two layers bubble or foam that are sandwiched between layers of 99.9% pure aluminum radiant barrier foil . this style can be used in a variety of applications because of its thin, lightweight properties. The bubble layers creates Maximum R value and Vapor barrier , the reflective foil on both sides allow it to reflect 97% of radiant heat away from a structure on the outside and back into a structure from the insides. This is why it works effectively in both hot and cold climates

1 | 99.9% pure aluminum |

2 | High Reflectivity 97% |

3 | Low Emissivity 0.003 |

4 | 0.04 mm thick aluminum foil |

5 | Single layer thick Polyethylene bubbles |

6 | 3.5mm+thickness |

7 | If Fire proof,the rate is Class A |

8 | 100% Vapor barrier |

- Q: Rock wool, EIA inorganic insulation mortar, polystyrene particles, polystyrene foam board advantages and disadvantages comparison?

- Polyphenyl granule thermal insulation slurry: polyphenyl granule heat preservation slurry is composed of polyphenyl granule and heat preservation rubber powder material. This kind of thermal insulation material water absorption rate is higher than other materials, use must do crack waterproof layer, fire rating is B2 grade, crack resistant waterproof protective layer material by crack cement mortar composite glass fiber network.

- Q: What are the properties of fire-resistant coatings for steel structures?

- Ultra thin structure fire retardant coating refers to the coating thickness of 3mm (including 3 mm) less than, decorative effect is good, high temperature can expand foaming, fire-resistant limit is generally less than 2 H steel structure fire retardant coating. This kind of fire retardant coatings for steel structures is generally solvent system, bonding strength, weathering has good water resistance, good leveling, good decorative features such as superior; subjected to fire slow expansion foam fire insulation layer to form a dense solid, the fireproof layer has a strong impact resistance, the temperature rise of steel delay, effective protection of steel member. Ultra thin intumescent steel structure fire retardant coating can be sprayed, brushed or rolled. It is generally used in building steel structures with a fire resistance requirement of less than 2 h. At present, there has been a fire resistance to meet or exceed the new ultra-thin fireproof coating for steel structure of 2 varieties of H, it is mainly based on the special structure of the poly methyl acrylate or epoxy resin and amino resin, chlorinated paraffin, compound as base adhesive, with high degree of polymerization of ammonium polyphosphate, melamine and pentaerythritol, double as the fire retardant system, adding titanium dioxide, wollastonite and other inorganic refractory material, using 200# as solvent and solvent oil compound. At present, all kinds of light steel structure, grid and so on, use this type of fire retardant coatings for fire protection. Because this type of ultra-thin fireproof paint coating, making use of thick and thin fire retardant coating for steel structure is greatly reduced, thereby reducing the total cost of the project, the steel structure has been effective fire protection, is currently promoting varieties on the market.

- Q: Advantages of exterior wall energy saving and environmental protection heat insulation coating

- At present, there are many kinds of exterior wall insulation materials in the market, which can be divided into organic insulation materials and inorganic insulation materials. Materials are inorganic active insulation materials, foam, mineral wool products, foam glass, expanded perlite insulation, powder particles insulation slurry EPS, spraying mineral cotton, foam cement insulation products, vacuum insulation panel etc..

- Q: What are the kinds of fire door core board?

- Inorganic fireproof insulating material, fire door core, such as rock wool, mineral wool, glass wool, aluminum silicate cotton, asbestos, expanded perlite, expanded vermiculite products, foam glass, microporous calcium silicate products. Inorganic materials are far better than organic materials and fire insulation performance and smokeless toxic performance, but there are some limitations, some non compressive degrees, must be attached to support carrier, carrier and brought fire and burning smoke toxicity problems, such as rock wool, mineral wool, glass wool, cotton, aluminium silicate asbestos is such; some high prices, the production of high energy consumption, such as foam glass, microporous calcium silicate in the case of such refractory; some itself is not high, moisture absorbent is large, such as cement or water glass based products, perlite cement or water glass based products, products such as vermiculite foam concrete is such, therefore restricted to varying degrees as the filling core material of the fire door.

- Q: Protective clothing is glass cotton wool type

- Rock wool, also known as asbestos, is a kind of mineral cotton. A fluffy short staple fiber made from natural rock and minerals. Rock wool is a kind of inorganic fiber made of natural rock, such as Xuan Wuyan, gabbro, dolomite, iron ore, bauxite and so on. It is made by melting and fibrosis at high temperature.

- Q: The difference between rock wool and mineral wool

- Cotton like short staple fibers made from silicate melts, including slag cotton, rock wool, glass wool and ceramic fibers, generally only refer to the first two.

- Q: What are the common thermal insulation materials?

- Main use of mineral cotton: its products are mainly used in the walls of dry buildings, roof, ceiling and other insulation, insulation and sound absorption, but also made of waterproof felt and pipe sleeve.

- Q: The water heater for what the security hole tube

- Gas water heater, smoke exhaust pipe, mineral wool, rock wool, glass fiber, etc..

- Q: What are the types of insulation materials used in pipes and equipment?

- Glass wool is a fibrous material made from the melting of glass or crushed glass. It consists of two kinds of short cotton and superfine cotton.Features: glass wool can maintain good insulation performance under high temperature and low temperature; has good elastic restoring force; has good acoustic performance of acoustic noise. Have good sound-absorbing effect; good chemical stability, no aging performance unchanged, thickness, density and shape can be processed according to user requirements.Main applications: short cotton is mainly made of glass wool felt and felt. It is used for heat insulation and sound insulation of buildings, heat preservation and sound insulation of ventilation and air conditioning equipment. Superfine cotton master

- Q: Exterior wall insulation putty powder construction needs to pay attention to what problems?

- The production enterprise of rock wool board insulation system should have professional guidance in the construction process, and cooperate with construction units and site supervision to do construction quality control work. Material access must be in accordance with specifications, quantity and quality requirements, after acceptance of qualified to storage, and should be kept by hand, is strictly prohibited open-air stacking. Curtain wall rock wool board should be overhead damp proof piling up. Plastering construction should meet the following requirements: rock wool board paste after surface treatment with plaster surface plate, scraping the mortar on the surface coated with a stainless steel spatula (thickness 1 ~ 1.5mm), and press the rock wool board surface fiber. Mortar should be configured in strict accordance with product instructions, configuration of the adhesive should avoid direct sunlight, and should be used within 2h.

Send your message to us

Rock Wool Roll Yellow Color Rock Wool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords