Rock Wool Board With ISO,BV,CE Certificate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 70 Cubic Meters 1*40HQ container m³

- Supply Capability:

- 70 Cubic Meters per Day m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

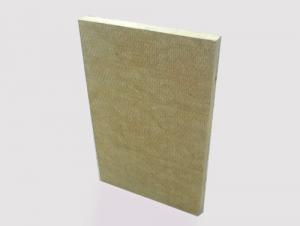

Rock Wool Board

1 Competitive products

2 Various size

3 Heat sound insulation

4 Fire prevention

Rock Wool Board Thermal Insulation With ISO, BV, CE Certificate

1.Introduction

The rock wool products regard basalt as its main raw materials, after the towering stove is melted, use high-speed acentric equipment to make basalt high-temperature melting body into inorganic fiber, and then put bond, polish, silicone oil in at the mean time. According to different requirements, we can manufacture many kinds of products, such as rock wool plate,rock wool tube and so on

.2.Performance

1.Good performance of thermal insulation, mechanical, fire prevention

2.High acidity ,having better chemical stability and fiber durability.

3. Low cost and high temperature resistance.

4. Good characteristics of sound absorption

- Q: What is the best sound proof cotton in the decorative plaster board partition wall? Mineral wool rock and glass wool.

- Rock wool and glass wool on the overall performance of almost the same, are brittle fiber composition, you need to get a good sound insulation, you need to use high-density materials, usually 80KG per cubic meter of the use of more. The price range is 40-60 yuan per square meter. This material can cause skin allergies and dust can cause respiratory allergies. Therefore, construction should pay attention to the construction personnel physical protection, materials must be completely sealed to the wall inside. If it is a ceiling with holes, you must not use glass wool.

- Q: How can the exhaust pipe of a gas water heater be insulated by going through the glass?

- Gas water heater exhaust pipe are now dual structure: the inner tube is the exhaust pipe, the fan will strong combustion exhaust water heater forcibly discharges the indoor air inlet pipe; the outer tube is, the outer air (oxygen) gas suction water heater for combustion.

- Q: What kinds of exterior wall thermal insulation materials are there in Northwest China?

- Experts from authoritative institutions of Beijing Haina LIAN inorganic fiber spraying technology Co., Ltd. development of ultra-fine inorganic fiber spray identified, it is for the further development of the enterprise is undoubtedly a new impetus. I learned that the evaluation results, both for the enterprise is also happy, for the enterprise how to further enhance their ability of research and development and to further explore this, more hope that the enterprises can take the assessment results in the East, as the struggle to make "Heiner fertility LIAN" on the floor again!

- Q: What's the difference between glass fiber and mineral wool?

- A fluffy short staple fiber made from mineral material. Including rock wool and slag cotton.

- Q: 8cm what is the sound volume of the soundproof cotton?

- Restate the professional point of view, the sound-absorbing material as insulation, sound-absorbing insulation materials or when used is not scientific. In both sound and sound (such as the design of reverberation time) when the need to use composite insulation board and sound-absorbing materials, can not only ensure the system sound transmission coefficient is small, and ensure the sound reflection weakened reach, sound insulation and sound absorption cream effect.

- Q: The difference between rock wool and mineral wool

- Cotton like short staple fibers made from silicate melts, including slag cotton, rock wool, glass wool and ceramic fibers, generally only refer to the first two.

- Q: The classification of exterior wall insulation and its main categories

- The first is the product standard, the complete expansion of polystyrene board external insulation board system, this system in our country now use probably accounted for more than 62%, some statistics in 80%, because the statistics are not accurate, but it is the highest market share, is also the most mature external insulation system.

- Q: What are the building thermal insulation materials in general?

- Building thermal insulation material is to take measures to reduce the heat inside the building to the outside, so as to maintain the indoor temperature of building. Building insulation material plays an important role in creating suitable indoor thermal environment and saving energy in building insulation.

- Q: What are the common thermal insulation materials?

- Mineral wool is the industrial waste slag as main raw materials by melting, cotton like insulation material made by injection method and centrifugal method: cotton is a natural rock as raw material is made of mineral wool. The commonly used rock such as Xuan Wuyan, diabase, amphibolite etc..Mineral wool characteristics: mineral cotton and products is a high-quality insulation materials, has more than 100 years of production and application history. The utility model has the advantages of light weight, heat preservation, heat insulation, sound absorption, good chemical stability, no burning and corrosion resistance, abundant raw material sources and low cost:

- Q: What are the differences and prices between rock wool board and mineral wool board?

- Rock wool and mineral wool belong to mineral wool, are made of natural rock, or (and) slag as raw materials, high temperature melting, formed in the interaction of centrifugal force and air under inorganic fibrous products;

1. Manufacturer Overview

| Location | Tianjin,China (Mainland) |

| Year Established | 1995 |

| Annual Output Value | |

| Main Markets | 30.00% Southeast Asia 20.00% Oceania 10.00% South America 10.00% Eastern Asia 10.00% Mid East 4.00% Africa 4.00% Northern Europe 3.50% Western Europe 2.00% Eastern Europe 2.00% North America |

| Company Certifications | ISO 14000:2004;Dec 16, 2011 -- Dec 16, 2011;ISO9001 Quality Management System Certificate;DNV Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Xingang Port,Dalian Port |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | 1,000-3,000 square meters |

| Product Price Range | Low and/or Average |

Send your message to us

Rock Wool Board With ISO,BV,CE Certificate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 70 Cubic Meters 1*40HQ container m³

- Supply Capability:

- 70 Cubic Meters per Day m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords