Good Quality Hydroponic Rock Wool Product

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Segment | Application | Recommended Products | Benefits | |

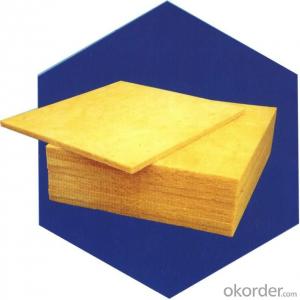

HVAC | Duct Thermal | 16 kg/m3 to 32 kg/m3 Rolls | • | Temperature control |

48 kg/m3 Boards | • | Fire safety | ||

Facing: FSK, Black FSK | • | Energy conservation | ||

Double sided FSK | ||||

Duct Acoustic | 48 kg/m3 Boards | • | Sound absorption | |

32 kg/m3 Rolls | ||||

Facing: BGT, FGT | ||||

AHU Room | 32 kg/m3 Rolls | • Sound absorption | ||

Facing: FGT, BGT | • | Temperature control | ||

Pre- | Metal Roof Insulation | 12 kg/m3 to 24 kg/m3 Rolls | • | Thermal comfort |

Engineered | Facing: FSK, WMP-VR, HSMAF | • | Sound absorption (eg. rain noise) | |

Metal | • | Eliminates requirement for 2nd skin | ||

Buildings | • | Lowest cost insulated solution | ||

• | Fire safety | |||

• | Easy to install | |||

• | Non corrosive to metal | |||

• | Aesthetically appealing | |||

Wall Cladding | 16 kg/m3 to 24 kg/m3 Rolls | • | Thermal comfort | |

Facing: FSK, WMP-VR | • Sound absorption | |||

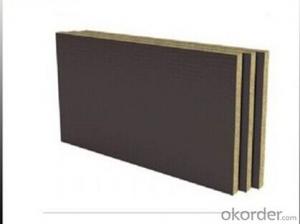

Rock wool board is made of select fine basalt as the major materials which is pulled into 4-7µ non-continuous fibers after melted by adopting advanced international four-roller centrifugal cotton-making procedures and adding a certain of adhesives, dust laying oil and water repellent into rock wool fibers. It can be made into products series with different density according to various uses through the technology of sedimentation, solidify, cutting and etc.

- Q: External wall insulation rock wool board construction points and matters needing attention, know how much?

- Rock wool, also called asbestos, is a kind of mineral cotton. It is made of natural rock and mineral and is made of fluffy, short and fine fiber.

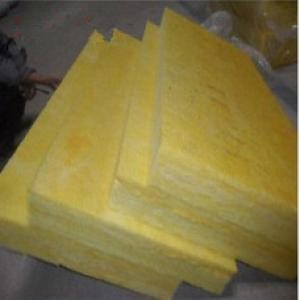

- Q: What is the best sound proof cotton in the decorative plaster board partition wall? Mineral wool rock and glass wool.

- At present, the market is the best sound effect is said to be gradient sound-absorbing cotton, as well as high barrier sound felt. The price is relatively high, the price range is 55-80 yuan per square meter. The advantages of its products are more environmentally friendly, first of all, the construction will not cause skin itching. No emissions. It won't be pulverized. The sound absorption effect is reflected in the full frequency silencing, and has a good reduction effect on low frequency, intermediate frequency and high frequency sound. High barrier acoustic felt is reflected in its high damping performance. It can effectively restrain the sound propagation caused by resonance when it is attached to the thin plate. Usually relatively high-end, or official sites are more respected.

- Q: What are the properties of fire-resistant coatings for steel structures?

- Ultra thin structure fire retardant coating refers to the coating thickness of 3mm (including 3 mm) less than, decorative effect is good, high temperature can expand foaming, fire-resistant limit is generally less than 2 H steel structure fire retardant coating. This kind of fire retardant coatings for steel structures is generally solvent system, bonding strength, weathering has good water resistance, good leveling, good decorative features such as superior; subjected to fire slow expansion foam fire insulation layer to form a dense solid, the fireproof layer has a strong impact resistance, the temperature rise of steel delay, effective protection of steel member. Ultra thin intumescent steel structure fire retardant coating can be sprayed, brushed or rolled. It is generally used in building steel structures with a fire resistance requirement of less than 2 h. At present, there has been a fire resistance to meet or exceed the new ultra-thin fireproof coating for steel structure of 2 varieties of H, it is mainly based on the special structure of the poly methyl acrylate or epoxy resin and amino resin, chlorinated paraffin, compound as base adhesive, with high degree of polymerization of ammonium polyphosphate, melamine and pentaerythritol, double as the fire retardant system, adding titanium dioxide, wollastonite and other inorganic refractory material, using 200# as solvent and solvent oil compound. At present, all kinds of light steel structure, grid and so on, use this type of fire retardant coatings for fire protection. Because this type of ultra-thin fireproof paint coating, making use of thick and thin fire retardant coating for steel structure is greatly reduced, thereby reducing the total cost of the project, the steel structure has been effective fire protection, is currently promoting varieties on the market.

- Q: What are the kinds of fire door core board?

- Organic thermal insulation material, fire door core is such as EPS (foam polystyrene), XPS (extrusion foaming polystyrene), foam PVC, foam PE, foam PUR and sponge rubber as raw materials and other products. But because of flammability and combustion of organic materials to produce VOC, hinder the application of these materials, this also appeared over the pursuit of improve flame retardant properties of organic materials, and enhance the level of fire safety phenomenon, it not only greatly increased the cost of materials, at the same time as the non environmentally friendly flame retardant are on fire the process will increase the amount of smoke and smoke toxic materials, fire may bring greater harm, so the organic material as the core material of the fire door is not desirable.

- Q: What kinds of exterior wall thermal insulation materials are there in Northwest China?

- At the same time it is also the first domestic production of inorganic fiber spraying cotton manufacturers, product quality is stable, a fire, my company production of inorganic fiber spraying equipment durable and convenient transportation has the advantages of small size, light weight, cotton speed, high construction efficiency, speed and other advantages, customer service maintenance. The standard of 6000 yuan / sets, at the same time the product uses a 380 volt -220 volt power supply, which greatly improves its safety and adaptability of the site. To provide a series of service system, our company has ever contracted projects, as the company grew, have business dealings we will build the first China fiber spraying service supermarket across the country, to provide value for all fiber spraying

- Q: Protective clothing is glass cotton wool type

- Rock wool protective clothing can choose special anti small dust protective clothing, such as DuPont tyvek1422a protective clothing, this kind of protective clothing is relatively good cost performance, but also inexpensive, can prevent 0.01 microns diameter foreign body.

- Q: What material is fast heated and kept warm?

- Heat the heating tube and the aluminum tube with the heat preservation material.There are many kinds of insulation products, including foam plastics, mineral cotton products, foam glass, expanded perlite thermal insulation products, rubber powder, EPS granule insulation paste, mineral spraying cotton and foamed cement insulation products.

- Q: What kinds of fire retardant coatings are there in steel structures?

- The utility model can be expanded and expanded slowly when the fire is in place to form a dense and hard fireproof heat-insulating layer, and the fireproof layer has strong fireproof impact property, and the temperature rise of the steel is delayed, and the steel member is effectively protected. Ultra thin intumescent steel structure fire retardant coating can be sprayed, brushed or rolled. It is generally used in building steel structures with a fire resistance requirement of less than 2 h. There have been fire resistance to meet or exceed the new ultra-thin fireproof coating for steel structure of 2 varieties of H, it is mainly based on the special structure of the poly methyl acrylate or epoxy resin and amino resin, chlorinated paraffin, compound as base adhesive, with high degree of polymerization of ammonium polyphosphate, double itrate alcohol, melamine as four fire retardant system, adding titanium dioxide, wollastonite and other inorganic refractory material, using 200# as solvent and solvent oil compound. All kinds of light steel structure, grid and so on, use this type of fire retardant coatings for fire protection.

- Q: How can the interior drain be silenced?

- A sewer pipe commonly used rock wool make noise processing (must be closed, it is said that rock wool can be carcinogenic) but in general, even a simple sound will hear the noise, just reduce it, if there is higher demand for insulation,You can also use wooden boards to make boxes, wrap the hose down, fill it with foam, and, with the aid of the ceiling material, reduce noise. Such as: sound-absorbing board, PVC foam board and so on.

- Q: Now, what are the new exterior wall thermal insulation materials?

- Red apple exterior wall paint, thermal insulation coating, the price is very high

Send your message to us

Good Quality Hydroponic Rock Wool Product

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches