Ringlock Scaffold Factory Produce for Building with SGS SGS AS/NZS1576.3 Certified CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Ringlock Scaffold Factory Produce for Building with SGS SGS AS/NZS1576.3 Certified

Type:Fixed

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Materials Standard:

Materials Specification:

Qualified Certificate:

Surface Treatment:

Standard Size:

Ledger Size:

Descriptions of Ringlock Scaffold Factory Produce for Building with SGS SGS AS/NZS1576.3 Certified

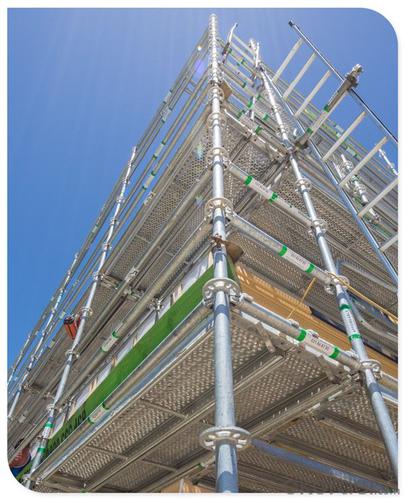

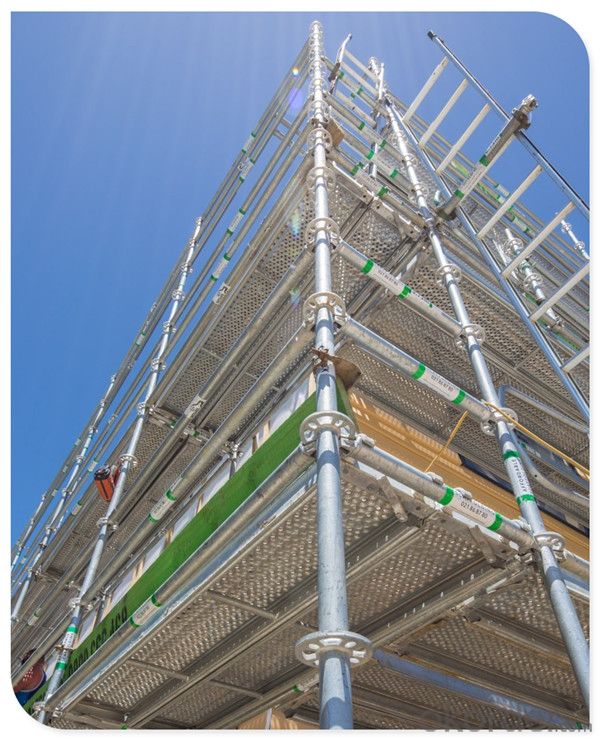

Ringlock is a modular scaffold system which can provide major savings in labor costs while meeting the demands for safety, ease of handling and reductions in maintenance.

Ringlock scaffold has the following features:

Quick erection: Ringlock scaffold are all pre-measured and just a hammer is required when erection.

Versatility: The revolutionary node point- rosette provides up to 8 connections in one plane, allowing the system scaffold highly adaptable for straight as well as curved structures, such as ship yards, power generation stations, petrochemical plants.

Low maintenance: The dip galvanized finish will greatly last the life of the products, no paint required, no more rust or corrosion, even they can be stored externally.

Safety: The reliable wedge connections prevent ledgers and diagonal braces from any kind of loosening, The rigid, right fit of all connections with concentric derivation of loads guarantees safety even at great heights. Reasonable customer requirement is acceptable

The System of Ringlock Scaffold Factory Produce for Building with SGS SGS AS/NZS1576.3 Certified

Ringlock

Scaffold

SystemStandard

Q345 tube

48.3*3.25Procedure Size Weight(kg) Surface Certificate

1.Cutting

2.Drilling

3.Plating cutting

4.Forming

5.Welding

6.Remove welding slag

7.Galvnize

8.Surface finish

9.Assembling

10.Packing

11.Logistics0.5m 2.96 HDG SGS ISO EN 1.0m 5.33 HDG SGS ISO EN 1.5m 7.73 HDG SGS ISO EN 2.0m 10.06 HDG SGS ISO EN 2.5m 12.42 HDG SGS ISO EN 3.0m 14.78 HDG SGS ISO EN Ledger

Q235 tube

48.3*3.250.73m 3.81 HDG SGS ISO EN 1.09m 4.93 HDG SGS ISO EN 1.40m 6.44 HDG SGS ISO EN 2.07m 8.71 HDG SGS ISO EN 2.57m 10.64 HDG SGS ISO EN 3.07m 12.41 HDG SGS ISO EN Brace

Q235 tube

48.3*2.51.5*2m 9.04 HDG SGS ISO EN 2.0*2m 10.05 HDG SGS ISO EN 2.5*2m 11.42 HDG SGS ISO EN 3.0*2m 12.13 HDG SGS ISO EN Bracket

Q345 tube

48.3*3.20.35m 4.5 HDG SGS ISO EN 0.75m 6.7 HDG SGS ISO EN 1.1m 9.9 HDG SGS ISO EN Plank

Q235

1.5mm

1.8mm0.73m 5.1 HDG SGS ISO EN 1.09m 6.9 HDG SGS ISO EN 1.4m 8.85 HDG SGS ISO EN 2.07m 12.11 HDG SGS ISO EN 2.57m 15.02 HDG SGS ISO EN 3.07m 17.69 HDG SGS ISO EN base

collar0.16m 1.7 HDG SGS ISO EN 0.2m 2.1 HDG SGS ISO EN Toe

board

wood

15*1.5cm0.73m 2.16 anti-fire ISO EN 1.09m 2.98 anti-fire ISO EN 1.57m 4.12 anti-fire ISO EN 2.07m 5.75 anti-fire ISO EN 2.57m 6.88 anti-fire ISO EN 3.07m 7.98 anti-fire ISO EN

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: HELP me out please. im struggling with this book

- I dont think she explained the rose bush very well. i think that it refers to Good and bad. Good being the rose and bad being the thorns Hester said in the book that she picked Pearl off a rose bush. Hester loves pearl but also fears her

- Q: Does anyone know the name of the song or perhaps have a link to the video if they have seen it on net for example on youtube.?

- Is there a bad song by Garth Brooks - no. I loved going to his concert in NYC central park. That had to be the best concert I ever attended. When he did The Thunder Rolls and had the sound effects of thunder to start the song it brought chills up my spine. Garth rocks!

- Q: Calculation method of complete scaffold

- The most distant light is closer to us than the nearest darkness:Distance is usually just a myth

- Q: Fastener type steel pipe scaffold composed of two components? What are the roles?

- Bowl buckle steel pipe scaffolding when using steel pipe, as a "single steel pipe scaffolding"; when using the steel cross bar, for the "steel pipe based scaffold".2.2 according to the vertical and horizontal transmission force between the vertical and horizontal1) the frictional force acting on the contact surface. That is, the friction force at the contact surface of the joint is pressed to support the load of the cross bar and is transmitted to the vertical rod;2) welding force. Most of the cross bar and vertical rod socket connection is used in this way, the door frame is also this way;3) direct pressure transmission. This method is more common in the horizontal bar placed in the top of the scaffolding;4) shear force of pin. That is to say, the connecting rod and the hole of the vertical rod are connected by the pin rod through the vertical connecting plate of the transverse rod to realize the double side shear action of the connecting rod and the pin rod. This method is rarely seen in the connection between the rod and the vertical rod.

- Q: by scaffolding ?

- I'm guessing it is a reference to large breasts. But I could be wrong.

- Q: Scaffold Piercing Aftercare?Ok, so I was looking into getting an industrial piercing. However, I am very very serious about the aftercare, and I would dread any infection or anything going wrong. So, I was wondering, what are some aftercare cleaning tecniques/methods? I already know that antibacterial soap is good, as is the H20 cleaning spray stuff. And that you are supposed to clean it twice a day. But how and when should I do this? I have school which I can clean it before I go in the morning, but I don't get back until four, and then I take a shower at night always. I know it sounds silly, but are there some tips you have? Thanks!

- i love my scaffold/business piercing i do not imagine it hurts yet some human beings say it does Coast round ?25/30 - any more desirable than its a rip off. this is a soreness to heal and takes a lengthy time period! each and every time I knocked mine it swelled and went humorous. extremely stressful. Had it executed 3 cases, 1st time it grew out, second time I only took it out. third time I were given it pierced on my different ear and at the same time as it became healed I replaced it to a versatile bar and for the reason that then this is been suitable. desire I helped.

- Q: Who has external scaffolding construction program

- See the following table for permissible deviation of steel pipe:Item deviation check tool1 welded steel pipe size (mm) outer diameter 48Wall thickness 3.5-0.5 vernier caliperThe 2 ends of steel tube shear oblique deviation 1.7 feeler, corner rulerThe corrosion of 3 steel tube outer surface depth of less than 0.50 vernier caliper4 kinds of rod end bending L = 1.5m = 5, steel ruler5 pole bending 3m<l = 4m4m<l = 6.5m = 12Less than or equal to 20

- Q: A 67.0- painter is on a uniform 21- scaffold supported from above by ropes. There is a 3.8- pail of paint to one side. The ropes are 1m inside the scaffold on each side. The pail is 1m away from the left rope and 3m from the right rope. The scaffold is a 6m. How close to the right end can he approach safely? How close to the left end can he approach safely?

- First of all...no units, no answer. Second of all...according to OSHA (Occupation Safety and Health Administration), NO ONE can walk on a scaffold beam outside the support ropes OR SET ANY OBJECT DOWN outside the support ropes. Hence the answers for both questions are 1 meter. It doesn't matter what a calculation will yield...NO ONE can walk on the beam outside the support ropes safely. Even if a torque balance yields that it will not put the ropes in compression and buckle them...it still isn't considered to be safe by OSHA if the painter is outside the ropes.

- Q: He pushes a can over the scaffold at 15 meters and it takes 3.25 seconds for it to land.I keep doing the problem over and over. the Correct answer is 20.5 m/s, however I keep arriving to the solution of 17 m/s. I solved it by doing Vf^2 = Vi^2 + 2adwhere the initial velocity is zero and the acceleration is -g. I made my coordinate system so that down is negative in which the distance will be negative. This however, did not give me the correct answer. Am I right or is the book right?

- The initial velocity is not zero since the scaffold is moving upward when the can gets pushed over. And final velocity, vf, does not represent the speed of the scaffold (if that is what you're trying to solve). y = (vo)(t) - (1/2)gt? 15 m = (vo)(3.25 s) - (1/2)(9.81 m/s?)(3.25 s)? vo = +20.5 m/s

- Q: how did they turn the cells into a polymer for the heart scaffold ?

- May have misunderstood. The heart is gently stripped of cells by using a detergent - this leaves the extracelllular matrix - a polymer of collagen - inert and insoluble. New cells (stem cells) will then be added to the structure to repopulate it with living heart muscle which gain coordination and structure from the matrix.

Send your message to us

Ringlock Scaffold Factory Produce for Building with SGS SGS AS/NZS1576.3 Certified CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords