Rewind Plastic Packing Bag For Food Packing

- Loading Port:

- China main port

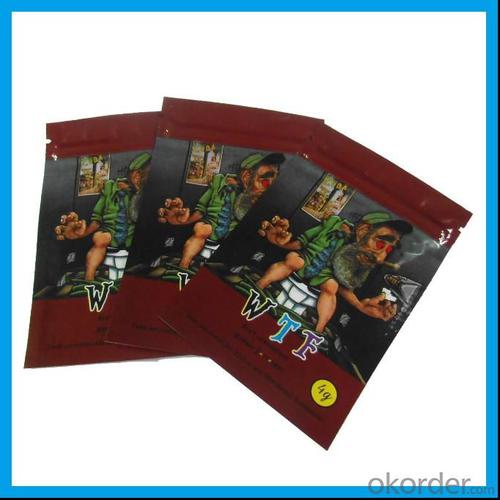

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 10000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Rewind Plastic Packing Bag For Food Packing:

Rewind Plastic Packing Bag For Food Packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

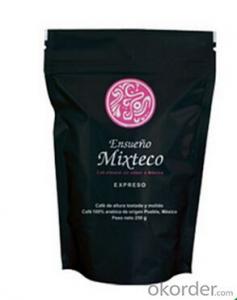

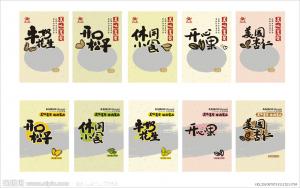

Rewind Plastic Packing Bag For Food Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Rewind Plastic Packing Bag For Food Packing:

Excellent quality control

Experienced factory produced

SGS passed

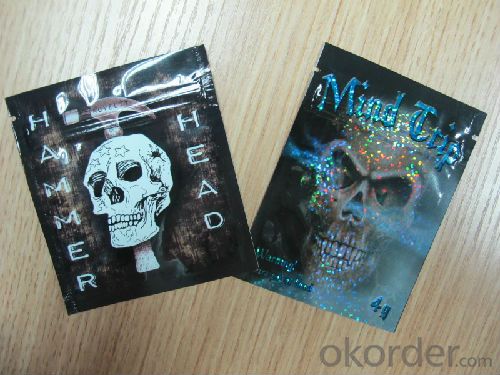

3. Rewind Plastic Packing Bag For Food Packing Photos:

4. Rewind Plastic Packing Bag For Food Packing Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Rewind Plastic Packing Bag For Food Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: The package specifications are 9 multiplied by 14 plus 3. How big is it?

- Now the standard of living has improved, basically vacuum packed bags. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: What is the material of detergent bag?

- Polypropylene English Name: Polypropylene, abbreviation: PP, commonly known as: 100 fold glue. Polypropylene is a representative of poly - alpha olefins, a thermoplastic resin made by the polymerization of propylene. Its monomer is propylene CH2=CH - CH3. According to the initiator and polymerization process, polypropylene can be divided into isotactic polypropylene and random polypropylene and syndiotactic polypropylene three configurations. Isotactic polypropylene is easy to form crystalline, high crystallinity reached more than 95%, the molecular weight of 8-15 million, giving it a good thermal and solvent resistance; atactic polypropylene at room temperature is white wax microstrip viscous a non crystalline, low molecular weight, in 3000-10000, the lack of irregular structure cohesion, application.

- Q: Can food wrap be heated in a microwave oven?

- There are two sides to consider1. sealed pockets are heated in a microwave oven, and the pressure in the bag is too large to explode! There are all the instructions on the microwave (as well as the eggs, and a hole). The microwave food I eat is also packed in plastic bags, but there's always room for gas2. material of packing bagGeneral contact with food bags, requirements are made of polyethylene (non-toxic, burning candles oil smell), general temperature 130 degrees, this pocket no problem (including the regular supermarket to buy plastic wrap and plastic wrap)However, there are a lot of cheap pocket (for example in the market and vest bag, supermarket cashier for plastic bags) are made of PVC, and can not contact with recycled plastic food; do not to mention (characteristics: cheap, taste, burning acrid smell)And, if it's made of polyethylene, don't heat it up with high oil food

- Q: Three layer coextrusion material for packaging bags

- At present, there are mainly two kinds of non PVC multilayer coextrusion infusion membrane: three layer structure and five layer structure.The performance of the layers of the three co extruded films for outer: block air, good printing performance; the middle layer with water resistance and anti permeability and elasticity; inner: non-toxic, good heat sealing and elasticity, and the solution has good compatibility.

- Q: Printing process of packaging bag

- For the surface or irregular surface can be used heat transfer, adhesion is good, not easy to fade, but requires a transfer equipment.Screen printing belongs to orifice plate printing. It is called four printing methods together with flat, convex and gravure printing. Hole printing includes transcription, mesh flower version, stencil printing and screen printing etc.. Printing the principle is: (a version of the base paper or other version of the film version of the ink can be made through holes) at the time of printing, through a certain pressure so that the ink to the substrate through the hole hole Edition (transfer paper, ceramics etc.) on the formation of images or text.

- Q: What material is the packing bag for pure milk, please?

- Lining, Xiong Xiaoli. Study on the separation of aluminum plastic paper composite packaging. Packaging engineering, 2008, 29 (12): 56-58.lixixiao2 (in TA) food grade polyethylene chen.1fan (TA station) composite layer of aluminium metal and linear PE, the middle layer there should be consistent with FDA zznjut (station link TA) composite and 100% more than one layer of polymer should be PE, the rest of the aluminum foil paper, duanyanjian (station TA) aluminum composite paper plastic bag

- Q: Which kind of transparent vacuum packing bag 16 wire and 24 wire?

- Suitable for your product packaging, like food packaging, of course, thin, see the product, electronic or hardware thick, anti puncture, of course, does not necessarily have to be very thick, suitable for good

- Q: How can the labels affixed to the bags be removed quickly?

- On the label with wind, a few minutes to unveil the label, the label will fall together with adhesive. Even at the stubborn stickers with traces of essential balm, and fingernails pull, usually can quickly clean up the traces.

- Q: Can the meat with plastic packing bag be pressed directly with a pressure cooker?

- It is better not to use a plastic bag directly with a pressure cooker heating, because it is said that plastic bags at high temperatures easy to precipitate toxic substances, so remove plastic bags and then heating for good, so as not to affect the health.

- Q: What is the difference between package material PETAL and VMPET?

- What is the difference between PETAL and VMPET performance?:PETAL material with high barrier, sealing, incense retention, shielding and other functionsVMPET material has higher decoration.

Send your message to us

Rewind Plastic Packing Bag For Food Packing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 10000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords