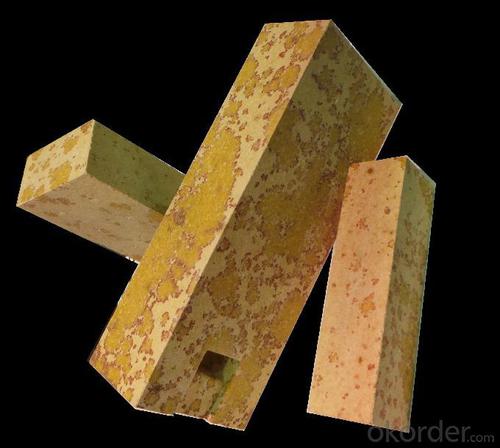

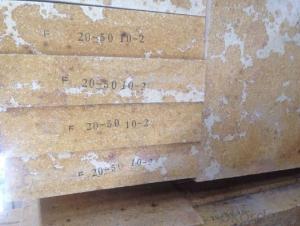

Silica Brick for Glass Furnace G-97A

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX silica brick using high quality silica as raw material to ensure superior performance of silica bricks, the raw materials is high quality dinas rock with SiO2 of 99% min. Its unique structure helps ease forming. Moreover, advantages of complete transformation after sintering and lower residual quartz enable to produce super-duty silica bricks.

Performance:

The silica bricks for glass furnace is characterized by high purity, less impurity, good corrosion resistance, higher bulk density, complete phase transformation, lower residual quartz, high RUL, lower thermal expansion and stable volume at high temperature. This leads to increase in service life of glass furnace and reduction in energy consumption. These products have found wide application in crown and key areas and been highly appreciated by clients.

Application

CMAX Silica bricks are commonly applied in

Coke oven

Hot blast stoves

Glass furnace

Technical Data

ITEM | For Hot-Blast Stoves | For Glass Furnace | ||||||

S-94 | S-95 | S-95B | G-94 | G-95A | G-95B | G-96A | G-96B | |

SiO2, % | ≥ 94 | ≥ 95 | ≥ 95 | ≥ 94 | ≥ 95 | ≥ 95 | ≥ 96 | ≥ 96 |

Fe2O3, % | ≤ 1.5 | ≤ 0.5 | ≤ 1 | ≤ 1.5 | ≤ 1.2 | ≤ 1.2 | ≤ 0.8 | ≤ 1 |

Residual Quartz, % | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 | ||||

Apparent Porosity | ≤ 23 | ≤ 23(24) | ≤ 21(23) | ≤ 24 | ≤ 22(24) | ≤ 22(24) | ≤ 22(24) | ≤ 22(24) |

True Density, g/cm 3 | ≤ 2.35 | ≤ 2.34 | ≤ 2.33 | ≤ 2.35 | ≤ 2.35 | ≤ 2.34 | ≤ 2.34 | |

Cold Crushing Strength, Mpa | ≥ 29.4 | ≥ 30(27) | ≥ 30(20) | ≥ 30 | ≥ 30(35) | ≥ 30(35) | ≥ 30(35) | ≥ 30(35) |

Refractoriness Under Load, º C | ≥ 1650 | ≥ 1600 | ≥ 1630 | ≥ 1660 | ≥ 1650 | ≥ 1680 | ≥ 1670 | |

Permanent Linear Change, % | 1500º CX4h, ± 0.2 | 1450º CX2h, ± 0.5 | ||||||

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Insulation of hot blast stove, key insulation silica brick hot stove, hot blast stove is shutdown or need repairing in blast furnace.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The high thermal conductivity of silica brick all inherits the advantages of traditional coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- The share of A12O3 and SiO2 is different

- Q: Which material is good for furnace refractory?

- Neutral refractory is mainly composed of alumina, chromium oxide or carbon. Corundum products containing more than 95% of alumina are a kind of high quality refractory materials with a wide range of uses. Chrome brick with chromium oxide as its main component has good corrosion resistance, but its thermal shock resistance is poor, and its deformation temperature is lower at high temperature. Carbon refractories with carbon bricks, graphite and silicon carbide products, low coefficient of thermal expansion, high thermal conductivity, good thermal shock resistance, high strength, resistance to acid and salt corrosion, especially weak acid has good resistance, without wetting of the metal and slag, light. It is widely used as lining material of high temperature, and also used as lining of autoclave in petroleum and chemical industry.

- Q: What are the main constituents of refractory bricks?

- (a) containing refractory brick brick, refers to more than SiO293%, is the main varieties of acid resistant brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: What is the silica refractory products?

- Refractory brick with silica content greater than 90%.

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

- Q: High temperature refractory material?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, the refractory material used for special occasions.Now the definition of refractory materials, has not only depends on whether the refractoriness at 1580 DEG. Refers to the current refractories used in metallurgy, petrochemical, cement, ceramics and other production equipment with inorganic non-metallic materials.

- Q: The formula in the refractory brick, and firing curve, who knows?

- Add 1.8-2.2% of the total weight of the main raw material, and then add lime milk, rolling for 10-15 minutes, and finally add pulp, rolling for 10-15 minutes, out of the mill, forming billet.

Send your message to us

Silica Brick for Glass Furnace G-97A

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords