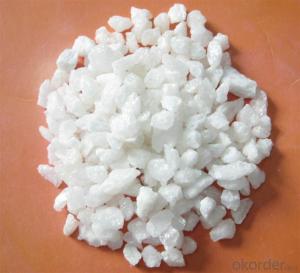

REFRACTORY GRADE WHITE FUSED ALUMINA FOR ABRASIVE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Henan, China

· Shape: Powder or Grain size

· Material: Alumina

· Al2O3:99%min

· SiO2:0.1%max

· Fe2O3:0.1%max

· NA2O:0.35%max

· Refractoriness (Degree):1770°< Refractoriness< 2000°

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy and Refractory

· Product name: White Fused Alumina

· Color: White

· Size:0-1mm/1-3mm/3-5mm/-200mesh/-325mesh

· Certificate:ISO9001

· Usage:Fire Resistance Place

· Type:Raw Refractory

· Packaging Details:Bags/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, you only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have other products?

A: Yes, please check our other products in website.

- Q: Does anyone know the characteristics of refractory for glass kiln?

- Quartzitic sandstone. Also known as quartzitic sandstone or white gravel. Which is a kind of natural refractory and quartz sandstone bonded by the kaolinite. Who appearance is better to be steel-grey, dense and hard, free of impurities and stripes. Its main crystalline phase is mainly quartz and kaolinite. Which has obvious stratified structure and anisotropism. The refractoriness fluctuation is between 1650~1730 ℃. The expansibility of quartzitic sandstone is different from that of silica?brick, who has maximum coefficient of thermal expansion under temperatures of 700 ~ 800 ℃, and it is most likely to burst at this time. The load softening temperature and the compression strength of calcined quartzitic sandstone have been improved significantly, with small residual expansion, stable volume, better thermal shock resistance, so it is generally to use calcinated quartzitic sandstone as refractories. which has been widely used as sidewall blocks on the small and medium sized furnaces.

- Q: What are the fire endurance requirements of class A fire resistant door ?

- Fire endurance of class A fire resistant door is 1.5h. According to the latest fire door requirements, in FMA FMB FMC three forms, A, B and C represent categories, such as FMA on behalf of Class A fire doors (ie thermal insulation fireproof door). Fire endurances of class A,B and C fire doors are 0.5 1.0 1.5 2.0 3.0. Therefore, the fire resistance of fire door needs to be designed and the design paper will make it clear in general.

- Q: Who knows about the fire endurance of A grade fireproofing glass doors?

- The fire endurance of grade A fire resistance rolling shutter doors should be no less than three hours. Fire doors can be divided into A, B and C grades according to their fire endurance which should be no less than 1.20 h, 0.90 h and 0.60h respectively. Places where are difficult to set fire-proof bulkheads can use fire resisting shutters as partitions of fire?compartments. The fire endurance of fire resisting shutters that include unexposed surface temperature rise as judging condition should be no less than 3 h. Fire resisting shutters that exclude unexposed surface temperature rise as judging condition should set up independent protection of closed automatic water spray system on both sides of shutters, and the duration of water spray system should be no less than 3.0 h.

- Q: What are the models of refractory cables?

- The models of refractory cables: NH-KVV22 copper core flame-retardant PVC insulated and fire retardant control cables with steel belt sheath NH-KVVRP copper core flame-retardant PVC insulated and fire retardant shielding control cables with steel braiding sheath NH-KVVP2 copper core flame-retardant PVC insulated and fire retardant shielding control cables with sheath and steel belt wrapping NH-KVVRP2 copper core flame-retardant PVC insulated and fire retardant shielding soft control cables with sheath and steel belt wrapping NH-KFF copper core fluorine plastic insulated and fire retardant control cables with sheath NH -KFFR copper core fluorine plastic insulated and fire retardant soft control cables with sheath NH -KFFP copper core fluorine plastic insulated and fire retardant shielding control cables with sheath and copper wire braiding

- Q: what's the classification of fireproof and thermal inuslation matertial?

- 1. thermal insulation material with A class combustion performance. Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite (2) thermal insulation material with B class combustion performance: extruded polystyrene board after special processing (XPS)/ polyurethane after special processing (PU) , phenolic aldehyde, gelatine powder polyphenyl granule. 3,thermal insulation material with B2 class combustion performance: molding polystyrene board(EPS), extruded polystyrene board(XPS), polyurethane (PU), polyethylene (PE),etc. sea capacity module and vitrified micro bead(cooperate with the innovator of vitrified micro bead, Liu Weihua) fireproofing issues have been completely solved.

- Q: What effect does aluminium powder play in refractory bricks?

- Aluminum powder is the main temperature resistant material ~ ~ ~ ~!

- Q: How long is the duration of fire resistance that fireproof door of level B can endure?

- The national standard for fireproof door of level B is 1.5h, which must be achieved. The data GB12955-2008 means that the door leaf of raw material is 0.8mm-1.2mm in thickness and door frame is 1.2mm-1.5mm in thickness. And other metal melting temperature shall not be less than 950℃, the duration of fire resistance shall not be less than 0.9 hours. Fire department will check and accept based on the manufacturer's inspection report, so you have to refer to manufacturer's inspection report if you want to know more in detail.

- Q: Does anyone know what is the use of waste refractory materials?

- Waste refractory materials can be 1, Recycled to do the aggregate and powder of castable , or make bricks. 2, can be reused after smash.3, Metal silicon is an anti oxidant in refractory material, mainly functioning as he oxidation resistance, at the same time improve its toughness.

- Q: What are the construction fire-proof materials?

- 1. fire?retardant?coating 2. fireproof?panel 3. fire proof and sealing material 4. flame resisting decorative materials 5. Green fire prevention materials

- Q: Where is the development of refractory industry?

- Refractories for continuous casting is an important part of the continuous casting machine, in addition to the characteristics of general refractory material, also for the purification of molten steel and improve the steel quality, stable molten steel temperature and composition, control and regulate the flow of the molten steel and other functions, so it is called functional refractories.

Send your message to us

REFRACTORY GRADE WHITE FUSED ALUMINA FOR ABRASIVE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords