High Alumina Brick - Refractory Firebrick SK36 Supplied by CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 40%~43% | Al2O3 Content (%): | 55%~58% | MgO Content (%): | 0.8-1.2 |

| CaO Content (%): | 0.01 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0.1~0.3% |

| SiC Content (%): | 0.00% | Model Number: | SK36 | Brand Name: | cnbm |

| Firebrick SK36 Bulk density(g/cm3):: | ≥2.25 | Firebrick SK36 Refractoriness(°C): | ≥1790 | Cold cushing strength (mpa): | ≥46MPa |

| SK36 Firebrick Porosity(%): | <23 | efractoriness under load 0.2mpa(°C): | >1450 | SK36 Firebrick Na2O+K2O(%): | <2.3 |

| Firebrick Thermal expansion at 1000°C(%): | ≤0.3 | Reheating shrinkingchange(%) 1500°CX24h: | -0.3 | Refractory SK36 Model Number: | DDSK36 |

| Refractory SK36 Brand Name: | DD |

Packaging & Delivery

| Packaging Details: | wooden pallet |

| Delivery Detail: | Shipped in 15 days after payment |

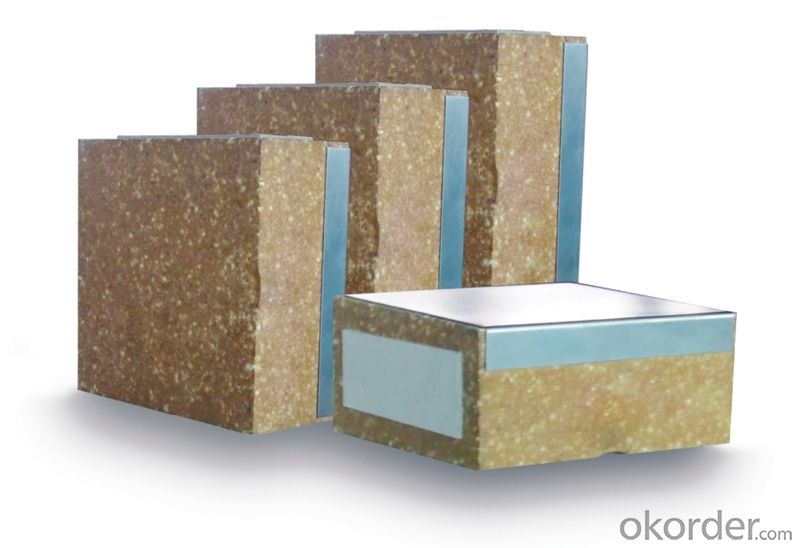

Factory supply refractory firebrick SK36

Category of Refractory Brick/Fire Brick:

a) According the made method, it can be divided into burnt brick, unburned brick, and electric smelting brick.

b) According the shape and size, it can be divided into standard brick, general brick and abnormal shape brick.

c) According the content of the Al2O3, it can be divided into fire clay brick and high alumina firebrick.

Firebrick SK36 Index

Item | SK38 | SK37 | SK36 | SK34 |

Al2O3 % | ≥75 | ≥65 | ≥55 | ≥48 |

Cold crushing strength ,MPa | ≥54 | ≥49 | ≥44 | ≥40 |

Apparent porosity ,% | ≤23 | ≤23 | ≤22 | ≤22 |

Refractoriness under load , °C | ≥1520 | ≥1500 | ≥1470 | ≥1420 |

Reheating linear change (1500°C,2h) % | +0.1-0.4 | +0.1-0.4 | +0.1-0.4 | (1450°C,2h)+0.1-0.4 |

Refractoriness °C | >1790 | >1790 | >1770 | >1750 |

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- From the year 2015 to the year 16 the end of the year, refractories industry presents two kinds of situations: one is a small business, a single product variety and equipment, to meet the demands of both environmental protection and the downstream market, such enterprises are generally in the Qing state inventory;

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: How many cubic bricks does a high alumina brick have?

- It is related to the content of aluminum in high alumina bricks.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- Box annealing furnace application: mainly used for quenching, normalizing, annealing and other conventional heat treatment equipment for steel parts. Features: 1, electric loading, high productivity, heat treatment is especially suitable for small and medium-sized parts, such as 30%, uniform temperature, intelligent digital display meter PID (pictured) automatic temperature control, high precision; 2, electric discharge loading convenient, as good; 3, door and seal the oven body is sealed automatically, without manual seal; 4, equipped with electric interlock protection device, and can prevent the fault accident due to the error. Bell type annealing furnace four bell type annealing furnace bell type annealing furnace is mainly used for annealing sheet metal in natural atmosphere and normalizing treatment of steel parts. 1, special steel, precision alloy large all fiber trolley type resistance furnace, strip, wire bright annealing. 2 、 annealing of special steel casting and forging. 3. Annealing of silicon steel sheet. 4, metal and non metal powder sintering pieces etc..

- Q: What are the common thermal insulation materials for thermal conductivity?

- The vacuum heat insulation plate is a kind of high efficiency thermal insulation board made of inorganic fiber core material and high resistance gas composite film. It is made of vacuum encapsulation technology and covered with special interface mortar.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Halide. A few species, about 120 species, accounting for only 0.1% of the earth's crust. Most of them formed in the surface conditions, forming a salt mineral, containing less pigment ions, light color, low hardness, generally less than 3.5. Common mineral halite (NaCl), potassium (KCl), fluorite (CaF2) etc..

- Q: What is spalling resistant high alumina brick?

- Spalling resistant high alumina brick is a kind of high alumina brick. Antistripping high alumina brick with high grade bauxite and containing Zr02 synthesis as raw material, according to a certain proportion by high pressure molding system in sintering products, products with anti stripping ability, and have the anti erosion potassium, sodium, sulfur, chlorine and alkali salt, low thermal conductivity and other properties that is the transition zone of cement kiln and decomposition of ideal material with remarkable characteristics, the product is good thermal shock resistance, strong ability to adapt to the environment. It is used in the preheating or decomposing furnace, grate cooler and so on.

- Q: What does refractory consist of?

- According to the chemical characteristics of refractory raw materials can be divided into acidic refractory materials, such as silica, zircon etc.; neutral refractory raw material, such as corundum, bauxite, mullite (acidic) (acidic), Ge (alkaline) iron and graphite; alkaline refractory materials, such as magnesite, dolomite, magnesium sand calcium sand.

- Q: What kind of material is the general metal case?

- Ordinary computer chassis and the material itself does not produce high-energy radiation, only in the space environment of the computer is the external defense requirements, and in the space structure, the use of lead as protective materials, unbearable weight.

Send your message to us

High Alumina Brick - Refractory Firebrick SK36 Supplied by CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords