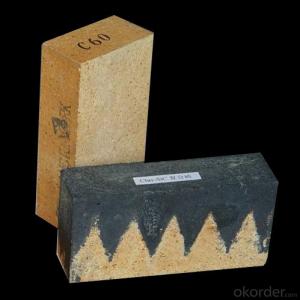

High Alumina Brick - SK36 & SK38 Refractory Bricks

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fire clay brick SK32,SK34,high alumina brick SK36,SK38

Sk36 And Sk38 Refractory High Alumina Brick

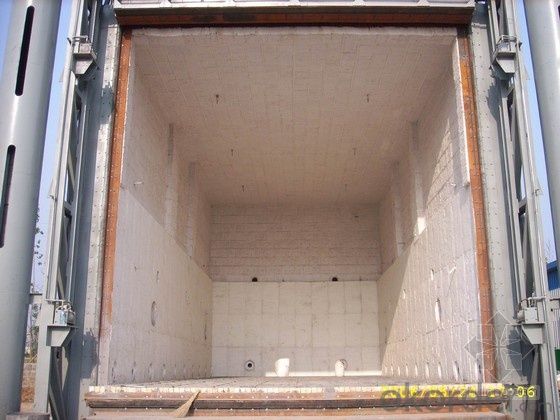

It is widely used in metallurgy, petroleum, chemical industry, building materials, machinery processing, military, etc of thermal technology equipment.It is widely used for MgO Reduction Furnace, Blast furnace, Hot Blast Stove, Tunnel kiln , Steel Ladle, Steel smelting furnace, Coke oven,chimney,Waste incinerators ,Casting products, Boilers, Cement kilns, Carbon furnace, Glass kilns and a variety of furnace linings and thermal equipment.etc.

Sk36 And Sk38 Refractory High Alumina Brick

Specifications

refractory brick Al2O3:65%

2.B.D:2.4--2.5g/cm3

3.Fe2O3:less than 2%;

4.Porosity:20%--22%

5.CCS:25MpaSk36 And Sk38 Refractory High Alumina Brick

- Q: What are the grades of high alumina bricks?

- High alumina brick according to the aluminum content is generally divided into: super high alumina brick, a high aluminum brick, two high alumina brick, three high alumina brick

- Q: What is the standard size of high alumina brick?

- The country has laid down a number of criteria for the use of refractory bricks to unify market demand.

- Q: What's the price of high alumina refractory bricks?

- The price of high alumina refractory bricks varies greatly according to the content of AL2O3.

- Q: Difference between low creep high alumina brick and ordinary high alumina brick

- The emphasis is on the physical and chemical indexes of low creep and high alumina bricks. The physical and chemical indexes of the high alumina bricks are different, too. They are DRL-1550And LZ-75 perform GB GB/T2988-2012

- Q: What are the characteristics of high alumina bricks?

- High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining. High R.U.L, low creep high alumina brick with high grade bauxite, fused corundum, fused mullite as main raw material of high-grade refractory materials.

- Q: Corundum, high alumina and fireclay refractory difference is what

- In fact, they are not consistent with raw materials, corundum refractories can use white corundum, white corundum, brown corundum corundum material, alumina content of these materials is higher than 90%, while the high aluminum refractory material is bauxite, alumina in 90 to less than 70, and clay raw materials the aluminum content is less than 70..

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Hollow brick is divided into cement hollow brick, clay hollow brick, shale hollow brick. In March 2011 Yunnan Yingjiang earthquake occurred in 5.8, the use of cement hollow brick houses collapsed and killed several people, due to safety concerns that Yunnan intends to disable the cement brick, Shandong Qingdao in the construction of real estate has also been halted the use of cement hollow brick. Professional claims in the construction industry argue that the prohibition of the use of such statements is unscientific and unprofessional. Misleading the public, it must be corrected. Hollow brick is only a kind of building material, and it is no problem to use it in scientific way. Hollow brick in use is very scientific, high quality requirements, the investigation of the foundation is suitable for the use of hollow bricks, how to design, construction, cement and other related ingredients, there are no problems. According to strict procedures, scientific use, strict implementation of relevant national standards, the use of qualified hollow bricks, there is no problem. Similarly, if the use of solid bricks does not strictly comply with the relevant standards of the state, the same will be a problem.

- Q: What is the apparent porosity of high alumina brick?

- Total porosity is porosity refers to the total volume of sample porosity in the percentage of total volume of samples. Apparent porosity refers to the percentage of the total volume of openings, pores, and total specimens in the sample.

- Q: What is the difference between metal compounds and metal solid solutions?

- Sigma phase belongs to Affirmative system, there are 30 atoms in the unit cell, two element alloy, sigma phase formation is related with the following conditions: (1) the atomic size difference, phase difference between the maximum sigma atomic radius of a tungsten cobalt, the atomic radius difference is 12%. (2) there is a set of cubic lattice elements (coordination number 8), and another component is face centered cubic or dense six square lattice (coordination number is 12). (3) appear in "average number of races" (s+d layer electron number) in the range of 5.7 ~ 7.5. The region of the presence of sigma in the two - element alloy is shown in table 3. In the three element system, the concentration and temperature range of the formation of the sigma phase are affected by the addition of third components. Usually in chromium stainless steel in Fe Cr phase, in Fe - Cr - Mn three yuan, sigma phase iron chromium and chromium can form Mn two element, when the addition of manganese in stainless steel, will promote the formation of sigma phase, and stabilizes the wide temperature range. Many of the Fe Cr alloy elements. The phase temperature range increases. In less than 820C stable Fe Cr phase, silicon promotes the formation of D phase and the stable temperature increased to 900 to 960 DEG C, manganese and molybdenum can improve the temperature stability of sigma phase to 1000 DEG C.

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- Because the hot air outlet of the top burning hot blast furnace is high, the installation requirement of the hot air manifold is high, and the requirement of the strength of the pillar structure is higher, so the rectangular arrangement of the hot blast stove is arranged. The top burning hot blast stove is located on the furnace top because of burner and hot air valve,Therefore, operation, maintenance and installation all require mechanization and automation. Also, because these water cooled valves are mounted with a high elevation,Therefore, the demand for cooling water supply pressure should be improved accordingly, the use of large top burning hot blast stove, the key lies in the design of high-power high-efficiency short flame burner. The top combustion hot blast furnace absorbs the advantages of internal combustion and external combustion hot blast stoves, and overcomes some of their shortcomings,Its structure can meet the requirements of modern blast furnace for high temperature, high pressure and large scale development,Combustion capacity, while meeting production requirements, has been successfully reduced by many devices,

Send your message to us

High Alumina Brick - SK36 & SK38 Refractory Bricks

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords