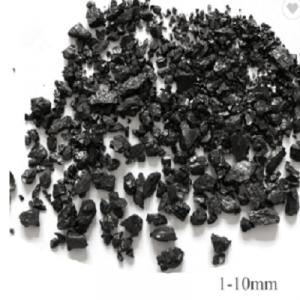

Recarburizer 94% F.C Higher quality and Lower price

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of graphite powder:

- 98%-99% graphite powder

- high fixed carbon

- low sulphur and nitrogen

- ten year experience in processing of graphite products

- Graphite powder / Graphite carburant

Graphite powder purposes:

- As non-metallic mineral resources, has important defense strategic role

- Can be used for high and new technical projects, is of great economic and social benefits

- Is the metallurgical industry refractory material

- Is the chemical industry all kinds of corrosion of vessels, general equipment of carbon products

- Light industry is in pencil, ink and the main raw material of artificial diamond

- Is the electrical industry production carbon electrode and electrode carbon rods, battery materials

Graphite powder data sheet:

Our carbon additive has the features of high carbon, low sulphur, nitrogen and harmful impurities. So it has been widely used for steel-smelting, casting, brake pedal and friction material. | |||||||

Data sheet | |||||||

Product No. | Fixed Carbon | Sulphur | Ash | Volatile Matter | Moisture | Particle Size | Nitrogen Content |

Min | Max | Max | Max | Max | 90% | Max | |

HY-CA-01 | 98.5% | 0.50% | 0.80% | 0.80% | 0.50% | 1-5MM | N/A |

HY-CA-02 | 99.00% | 0.30% | 0.50% | 0.50% | 0.50% | 1-5MM | 100PPM |

HY-CA-03 | 98.50% | 0.05% | 0.80% | 0.70% | 0.50% | 0.3-5MM | 300PPM |

HY-CA-04 | 95.00% | 0.30% | 3.50% | 1.50% | 0.50% | 1-4MM | 700PPM |

HY-CA-05 | 99.00% | 0.03% | 0.50% | 0.50% | 0.50% | 0.3-5MM | 300PPM |

HY-CA-06 | 80.00% | 0.10% | 16.50% | 3.50% | 2.00% | 1-5MM | N/A |

Remark:The above mentioned grain sizes are recommended standard, if your have special requirements, please feel free to contact us. | |||||||

- Q: What materials can be carbonitriding?

- Low temperature carbonitriding for high alloy tool steel, high-speed steel tools, etc., in temperature carbonitriding is under great pressure not only in carbon steel wear parts, high temperature carbonitriding is mainly used for medium carbon steel and alloy steel under great pressure.

- Q: Is there any difference between carbon plate and universal board?

- Generally referred to as "Pu plate" is "hot-rolled ordinary carbon structural steel plate", usually refers to single rolled steel plate (original flat plate). The common grades are: Q235, Q345, SS400, St12 and so on.Usually referred to as "carbon tie plate" refers to the "ordinary carbon structural steel hot-rolled coil", refers to the continuous rolling process with hot rolling mill rolling, finished products are steel coil delivery of ordinary carbon steel plate (coil).

- Q: Carbon injection molding machine heating several degrees

- The quick test method for judging drying effect is to use the "air injection" on the injection molding machine". If the material flowing slowly from the nozzle is uniform and transparent, light silver strips and bubbles, is qualified. This method applies to all plastics.The melt viscosity of PC is much larger than that of PA, PS, PE, and the flowability is poor. Melt flow properties close to Newtonian fluid. The viscosity of the melt shear rate had little effect, and is very sensitive to changes in temperature, therefore, only by adjusting the molding processing temperature, viscosity can effectively control PC.The selection of molding temperature is relative to the average molecular weight of the resin and its distribution, the shape and size of the product, the type of the injection molding machine, and so on. It is generally controlled in the range of 250~310 centigrade. For injection molding, the resin with relatively low average molecular weight should be selected, MFR is 5 to 7g/10min; complex shape or thin wall products. Molding temperature should be high, 285~305 degrees; and thick wall products, molding temperature is slightly lower, to 250~280 degrees. Different injection molding machine, molding temperature is not the same. The screw type is 260~285 degrees, and the plunger type is 270~310 degrees centigrade. The setting of the material temperature is in the form of front high and low, near the end of the hopper, the temperature of the barrel should be controlled above the softening temperature of PC, that is greater than 230 degrees, to reduce the material resistance and injection pressure loss. In spite of increasing molding temperature, melt filling is beneficial. But not more than 230 DEG C, otherwise PC will degrade, make the products become darker in color, appear on the surface of silver, dark, black spots, bubbles and other defects, at the same time, the physical and mechanical properties will be significantly decreased.

- Q: How does carbon affect the formation of toxic algal blooms?

- Toxic algal blooms can be influenced by carbon in both direct and indirect ways. Eutrophication is one direct effect, where carbon, in the form of organic matter, enters water bodies from various human activities. This excess carbon acts as a nutrient for algae, promoting their rapid growth and leading to algal blooms. Another direct effect is the impact of carbon on the composition of algal communities. Certain algae species, known as harmful algal blooms (HABs), can produce toxins that are harmful to aquatic organisms, humans, and animals. The concentration of carbon can influence the growth and dominance of HABs, creating favorable conditions for their development. Furthermore, carbon affects the chemistry of the water, including its pH levels. Changes in pH can significantly affect the physiology and behavior of algae. Some toxic algae species are more tolerant of low pH levels, which can be worsened by increased carbon dioxide levels in the water. This creates an environment that favors the growth of harmful algal blooms. Indirectly, carbon can also impact the temperature and nutrient dynamics in water bodies. Climate change, driven by increased carbon emissions, can result in warmer temperatures, which stimulate algal growth. Additionally, changes in nutrient availability due to carbon-induced alterations in the water cycle can favor the development of toxic algal blooms. In conclusion, carbon plays a significant role in the formation of toxic algal blooms through eutrophication, changes in algal community composition, alterations in water chemistry, and indirect impacts on temperature and nutrient dynamics. Understanding these relationships is crucial for developing strategies to mitigate the occurrence and impact of harmful algal blooms.

- Q: What are the impacts of carbon emissions on the stability of kelp forests?

- Kelp forests are significantly affected by carbon emissions, which have a major impact on their stability. The increased levels of carbon dioxide in the atmosphere lead to ocean acidification, causing harmful effects on kelp. When carbon dioxide dissolves in seawater, it creates carbonic acid, which lowers the ocean's pH. This acidification prevents kelp from growing and developing properly, making them more vulnerable to stressors and reducing their overall stability. Ocean acidification affects kelp physiology in various ways. It impairs their ability to absorb essential nutrients like nitrogen and phosphorus, which are crucial for their growth. This nutrient deficiency weakens the kelp, making them more susceptible to diseases, predation, and damage from storms. Moreover, acidified seawater hinders the development of kelp spores, which impairs their ability to reproduce and regenerate kelp forests. Furthermore, carbon emissions contribute to the increase in sea temperatures, which also harm kelp forests. As the climate warms, kelp may face thermal stress, resulting in slower growth rates and higher mortality rates. Warmer waters also create favorable conditions for harmful algae species, which can outcompete kelp for space and resources, further destabilizing kelp forests. The stability of kelp forests is crucial because they provide numerous ecosystem services. They act as important carbon sinks, absorbing and storing large amounts of carbon dioxide from the atmosphere. Kelp forests also serve as habitats and nursery grounds for a wide range of marine species, including commercially important fish and invertebrates. They play a vital role in maintaining the health and productivity of coastal ecosystems by reducing coastal erosion, improving water quality, and supporting biodiversity. To mitigate the impacts of carbon emissions on kelp forests, it is crucial to reduce our carbon footprint by transitioning to cleaner and more sustainable energy sources. Additionally, protecting and restoring coastal habitats, including kelp forests, can enhance their resilience to climate change and other stressors. Implementing sustainable fishing practices and establishing marine protected areas can also help preserve and maintain the stability of kelp forests and the valuable ecosystem services they provide.

- Q: How is carbon dioxide released into the atmosphere?

- Carbon dioxide is released into the atmosphere through various natural and human activities. Natural processes like volcanic eruptions and the decomposition of organic matter release carbon dioxide. However, human activities such as burning fossil fuels, deforestation, and industrial processes are the primary sources of carbon dioxide emissions into the atmosphere.

- Q: What are the main sources of carbon emissions?

- The main sources of carbon emissions are primarily attributed to human activities, particularly the burning of fossil fuels such as coal, oil, and natural gas. The combustion of these fossil fuels for electricity generation, transportation, and industrial processes releases significant amounts of carbon dioxide (CO2) into the atmosphere. Another major source of carbon emissions is deforestation and land-use changes. When forests are cleared or burned, the carbon stored in trees and vegetation is released as CO2, contributing to greenhouse gas emissions. Additionally, the loss of forests reduces their ability to absorb carbon dioxide through photosynthesis, exacerbating the problem. Industrial processes such as cement production and chemical manufacturing also generate substantial carbon emissions. Cement production, in particular, is responsible for a significant amount of CO2 due to the chemical reactions involved in the production of cement. Agriculture is another source of carbon emissions, primarily through the release of methane (CH4) and nitrous oxide (N2O). Livestock farming, especially cattle, produces methane through enteric fermentation and manure management. Nitrous oxide is released from the use of synthetic fertilizers and manure in agricultural practices. Finally, waste management and disposal contribute to carbon emissions. Landfills, where organic waste decomposes, release methane gas. Additionally, the incineration of waste also releases CO2 and other greenhouse gases into the atmosphere. Overall, reducing carbon emissions requires addressing these primary sources through transitioning to cleaner energy sources, promoting sustainable land-use practices, improving industrial processes, adopting more sustainable agricultural practices, and implementing effective waste management strategies.

- Q: What does carbon burning mean?

- As the word says, it is boiled and boiled with carbon

- Q: How is carbon used in the production of carbon fiber?

- Carbon plays a vital role in the production of carbon fiber. Carbon fiber production involves subjecting a precursor material, typically a polymer like polyacrylonitrile (PAN) or rayon, to a series of heating and chemical treatments. Initially, the precursor material undergoes carbonization, a process where it is heated to a high temperature without oxygen. This carbonization stage includes pyrolysis, which breaks down the molecular structure and eliminates non-carbon elements such as hydrogen, oxygen, and nitrogen. Once carbonization is complete, the resulting material becomes a carbon-rich structure referred to as char. However, it is not yet considered carbon fiber. To convert the char into carbon fibers, further processing steps called stabilization and graphitization are necessary. During stabilization, the char is exposed to heat in the presence of oxygen, resulting in the formation of cross-linked structures. This step enhances the fiber's thermal stability and prevents shrinkage or deformation during subsequent processing. Following stabilization, the material is heated at a higher temperature in an inert atmosphere during graphitization. This process aligns the carbon atoms within the fiber, creating a highly ordered and crystalline structure. Throughout this entire process, carbon serves as the primary constituent of the resulting carbon fiber. Starting from the precursor material containing carbon atoms, the carbonization and graphitization steps remove impurities and rearrange the carbon atoms, producing a durable and lightweight fiber. The resulting carbon fiber possesses exceptional properties, including high strength-to-weight ratio, stiffness, and resistance to heat and chemicals. These attributes make it a valuable material in numerous industries, such as aerospace, automotive, and sporting goods.

- Q: How is carbon used in water filtration systems?

- Carbon is commonly used in water filtration systems due to its impressive adsorption properties. Adsorption involves the molecules of a substance binding to the surface of another material, in this case, carbon. Activated carbon, which is carbon that has been specially processed to create a large surface area, is particularly effective in water filtration. When water passes through the filtration system, the carbon captures and retains a wide range of impurities, including organic compounds, chlorine, volatile organic compounds (VOCs), and certain heavy metals. This adsorption process helps to remove unpleasant odors and tastes from the water, making it more palatable. Carbon also plays a crucial role in removing potentially harmful contaminants such as pesticides, herbicides, and pharmaceutical residues. Additionally, carbon filtration systems can help reduce the risk of waterborne illnesses by removing bacteria, viruses, and parasites. Overall, carbon is an essential component of water filtration systems as it significantly improves the quality and safety of drinking water.

Send your message to us

Recarburizer 94% F.C Higher quality and Lower price

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches