Real Wood Veneers Cherry Engineered Wood Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of the Cherry Engineered Wood Veneer

| Length | 2150-3100mm |

| Width | 320-900mm |

| Thickness | 0.15-2.0mm |

| Normal size | 2500*640*05mm |

Instruction of the Cherry Engineered Wood Veneer

Engineered Veneer is a sliced reconstructed real wood veneer. It is made from natural timber

which color is enhanced, reformed to a square "log" and then re-sliced in rectangular veneer

sheets.

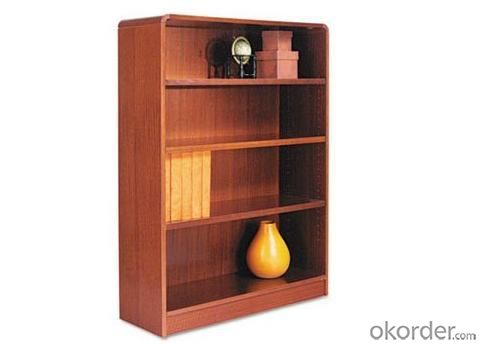

The usage of the Cherry Engineered Wood Veneer

It is widly applid in the following regions: door inserts, wall panels, ceiling panels, privacy

screens, architectural millwork, and furniture inlays, hotel, shopping mall, restaurtant, loung,

commercial space, chains, office, halll dinning, expo, column, furniture,slide door, interior door,

house, bar etc.

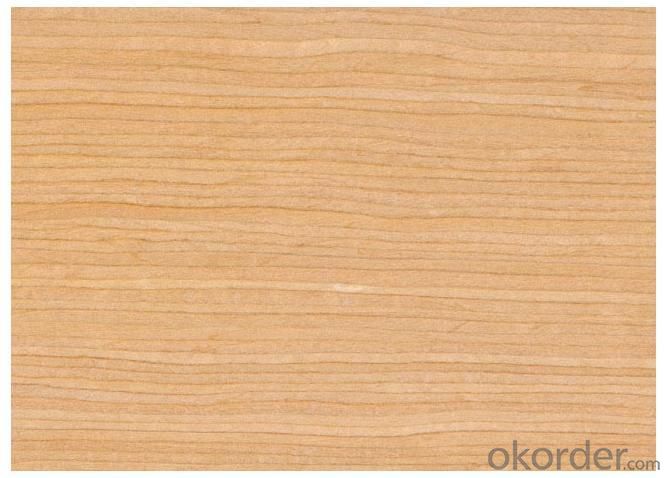

The main wood grain of Cherry Engineeres Wood Veneer includes

Teak, Oak, Elm, Wenge, Walnut, Cherry, Maple, Ash, Ebony, Zebrawood, Rosewood, Apricot,

Sapelli, Vine Burt etc.

The package of the Cherry Engineers Wood Veneer

Package details: Wood pallet packing and wrapped with waterproof plastic, then fixed by iron belt.

Delivery details: China main port and 7-30 days after we receive your deposit.

Engineered Wood Veneer are good used for furniture decoration

- Q: Advantages and disadvantages of Technology veneer and natural veneer

- In personal terms. Science and technology veneer in the next few years will be to a certain extent, replace the natural veneer. hope this helps. Pure hand hope to give points. You can also ask

- Q: Often, the processing of natural vines is done by slicing the method. The process flow is as follows

- The program is reasonable not only the high rate of production, and the system is made of chopped thin wood, chord thin wood, the resulting high value of decorative products.

- Q: Paste veneer craft specifically refers to what

- through unremitting efforts, independent research and development of "Jin Yi" hand paste veneer came into being The

- Q: What is the veneer process?

- especially not suitable for large arc substrate and the thickness of more than 0.3mm hard wood.

- Q: What can the veneer be classified?

- according to the manufacturing method of classification Can be divided into sliced thin wood; peeling veneer; sawing thin wood; semi-circular peeling veneer. Often the use of slicing method

- Q: The principle of veneer dyeing

- in the preservation of natural veneer original natural texture and texture at the same time, the veneer dyeing, so rich Color and wood texture with a different decorative effect

- Q: What is the veneer panel

- Veneer panel commonly known as panel. Is the solid wood board precision cut into a thickness of about 0.2mm meager veneer for the surface layer to the splint as the substrate,

- Q: Different cutting processes of wood veneer

- Domestic and foreign names are different, but are in the description of the same product

- Q: What is the size of the veneer?

- Simple veneer operation, will be applied to the veneer of the wood surface treatment is clean, there are rugged to be dealt with first flat

- Q: The Sliced ??veneer manufacturing process

- The width of the veneer is not less than the relevant requirement.

Send your message to us

Real Wood Veneers Cherry Engineered Wood Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords