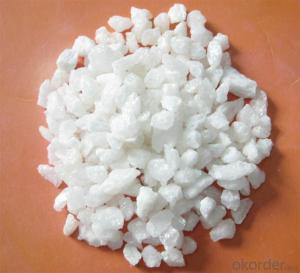

Raw Materials for Refractory - White Fused Alumina WF A with Good Price and Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

99.2% White Fused Alumina

1.high AL2O3 content:99.2%

2,high quality and competitive price

Name of goods:White fused alumina

size:3-5, 1-3, -1, 0.5-1, 0.5mm

Spec.:

Al2O3:>99.2%

SiO2:<0.1%

Na2O:<0.4%

Fe2O3:<0.1%

----------------------------------------

size:0-0.15mm

Spec.:

Al2O3:>99%

Na2O:<0.45%

Fe2O3:<0.15%

Packaging & Shipping

In 1MT jumbo bag or as the buyer request.

We ship the cargo in 20' GP containers,each container loads 25MT/20bags.

Application of White Fused Alumina

1.Light-weight insulating refractories

2.Shaped and unshaped refractories

3.Pre-cast shapes and castables

4.High Alumina Refractory mixes and gunning mixes

Our Services

1.We will keep the client informed about the cargo situation,from production time to the shipment.

2.We test samples picked up from the plant or loading port in our designated third party lab or SGS lab.We tes sample before every shipment to make sure each lot quality is good for our client.

- Q: What advantage and disadvantages it has compared to common fire insulation materials

- Main advantage of A-level fire proof heat retaining plate is A-level non-conbustibility. Now residential areas strictly require the external walls to be high-level fire proof, to be specific, high fire resistance, non combustible. Standards for evaluation varies according to different types, which includes anti-corrosion, acid and alkali resistance, waterproof, anti termites and so on. Disadvantage is the insulation effect is quite ordinary. It will absorb water, get deformed, need some water prevention measures after constrcuting thermal insulating layer for it. Its thermal conductivity far below the benzene plate, and plastic extruded palte, half the thickness of the polyurethane insulation layer can reach heat perservation effectiveness of the benzene plate and extruded plate of the same thickness.

- Q: How to use fire-resistant soil?

- Clay refractory soil 1, characteristics and uses: Clay refractory brick is a weak acid refractory material, its thermal stability is good, suitable for hot air furnace, all kinds of boiler lining, and flue, smoke room, etc.. 2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

- Q: How much modulus is used as refractories material of sodium silicate.

- Storage and use are very convenient, especially for mechanized and the evenly refractory material and the sodium silicatemodulus is generally...2. transportation. The appearance of product is pure white. Instant powdered sodium silicate, also known as instant sodium metasilicate.4 to 3, in powder form, automation. in the range of 3, hydrated sodium silicate

- Q: What is the function of refractory in ceramics?

- In addition, the quality of refractory determines the finish and color of ceramic glaze.

- Q: What's the classification of flameproof glass, the refractory time of fireproofing glass.

- who knows the classification of fireproofing glasses, how long is the fire-resistant time?

- Q: I would like to ask a friend that how much is the fire endurance of level A fireproofing glass?

- Fireproofing doors can be divided into Class A, Class B and Class C by the fire endurance, the fire endurance is seperately not less than 1.20h, 0.90h and 0.60h. Fireproofing glass is a kind of special glass which can retain its integrity and insulation in the prescribed fire test, it can be divided into three categories according to fire resistance rating: class A is the fireproofing glass with refractory integrity and refractory thermal insulation. Such glass has the properties of transmittance, fireproofing (smoke insulation, fire insulation, heat radiation shielding), sound insulation and shock resistance, which is suitable for architectural steel and wood fire doors, windows, partition walls, daylighting?roof, ceiling?screen, perspective floor and other building components required both transparent and fireproofing. Class B is a fireproofing glass with refractory integrity and thermal radiation intensity. Such fireproofing glass is mostly composite fireproofing glass with transmittance, fireproofing and smoke insulation. Class C is a fireproofing glass with refractory integrity. Such glass has the features of transmittance, fireproofing, smoke insulation and high strength. it can used in partition wall, fire window and outdoor curtain wall without the thermal insulation requirements. fireproofing glass can be divided into composite fireproofing galss and monolithic fireproofing glass by the structure.

- Q: who knows the fire resistant level of fireproof gypsum board ?

- The most commonly used ceiling decoration materials rates B1, including gypsum board, fibrous plaster, cement particle board, mineral wool sound-absorbing panels, glass wool decorative acoustic?panel?absorber, perlite decorating acoustic board, nonflammable plywood, nonflamable medium density fiberboard, mineral wool decorative board, flame retardant wood, aluminum foil composites, flame retardant phenolic plywood, aluminum foil glass fiber reinforced plastic composite materials. The fire gypsum board fire rating can reach A. Of course, many of the suspended ceiling gypsum board of inferior quality rates below B1. plasterboard is non-flammable B1 level products. There are introductions in Fireproof Specification of National Standard Building Interior Decoration Design. plaster board mounted on steel stud can be used as A level decoration materials. in accordance with the national fire safety rules on fire durance of walls and ceilings and other components. we can not simply say whether a piece of gypsum board can meet the requirements.

- Q: What kind of refractory decorative board has good quality?

- Baby Rabbit has excellent refractory decorative board. It once won the Chinese famous brand, and was awarded iconic brand in plywood industry and the most influential integrated service providers of indoor decoration materials . Fireproof?panel is made from body paper(titanium coated paper, kraft paper) in high temperature and pressure through impregnation technology of melamine and phenolic resin. Refractory door slab is made by sticking fireproof?panel on base materials such as density board or chipboard.

- Q: Can anyone tell me what is a high alumina refractory?

- Refractories refer to a class of inorganic non-metallic materials whose refractoriness are no less than 1580 ℃. Refractoriness is the Celsius temperature when cone-shaped samples can resist high temperature without softening and melting down in the absence of a load. But it is not accurate to define refractory merely by judging that whether the refractoriness is no less than 1580 ℃. Currently, the materials whose physical and chemical properties allow them to be used in high temperature environments are called refractories. Refractory materials are widely used in metallurgy, chemical industry, petroleum, machinery manufacturing, power and so on, among which the metallurgical industry is the largest demander in this regard, accounting for 50% to 60% of total output. Hope it will help you out!

- Q: What is the limit of fireproof rolling shutter?

- Fire proof door can be divided into Serie A, B and C in terms of fire endurance limit, fire resisting limit are not should be less than 1.20h, 0.90h and 0.60h. Set firewall has difficult sites can use fire shutter fire partition separating, when the back fire surface temperature rise refractory limit determination conditions of fire shutter, the fire resistant limit not less than 3H; when employed does not include back fire surface temperature rise do fireproof limit determination conditions of fireproof rolling curtain, on both sides of the shutter should be set up a separate closed type automatic water spraying system protection, sprinkler system continuation of time should not be less than three hours.

Send your message to us

Raw Materials for Refractory - White Fused Alumina WF A with Good Price and Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords